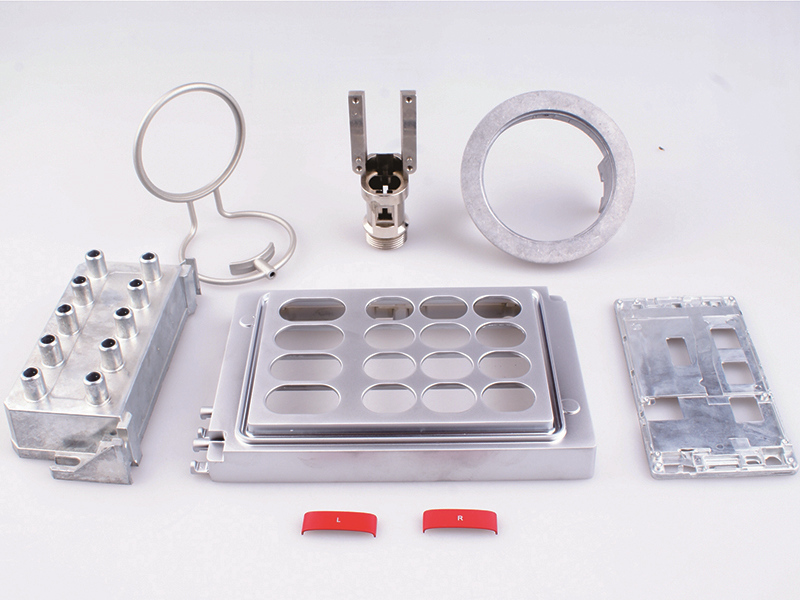

Excellent quality Sheet Metal Fabrication Process - Sheet Metal Fabrication For Headphone – Anebon

Based on the leader from markets and customers requirements, the company is developing steadily with professional standard constant improvements and technical innovation doing our best to provide customers with high performance toolings.

| Tool&Die Material | SKD11,DC53 ,45# steel,SKH-51,Cr12mov |

| Accuracy | 0.01mm |

| Capacity | Tool &die :30sets/month parts :1million /month |

| Design software | 3D:PROE UG 2D: auto CAD |

| Surface Treatment | Powder coating,Hot galvanized,Painting,Polishing,Brushing,Chrome,plating titanium |

| Test Equipment | Hardness tester,Chemical analysis,Digital Measuring Projector |

| Thickness | 0.1-10.0mm or other special available |

| Lead time | 15-55 days according to products |

| Standard | ANSI. API.BS.DIN.JIS.GB.etc |

| Equipment | 1) Stamping machine 2) CNC milling and turning, grinding, honing, lapping, broaching and other secondary machining. 3) integral CNC machineries & four machining centers, such as milling, broaching, drilling, turning, planning, grinding machinery and three-axle machining centers. |

| Productions Cover | Sheet metal auto parts, Auto stamping parts,Home Electrics stampingparts, Device stamping parts |

About our product:

1. Precision technology

2. Competitive price

3. Quality guarantee

4. Quick delivery

Write your message here and send it to us