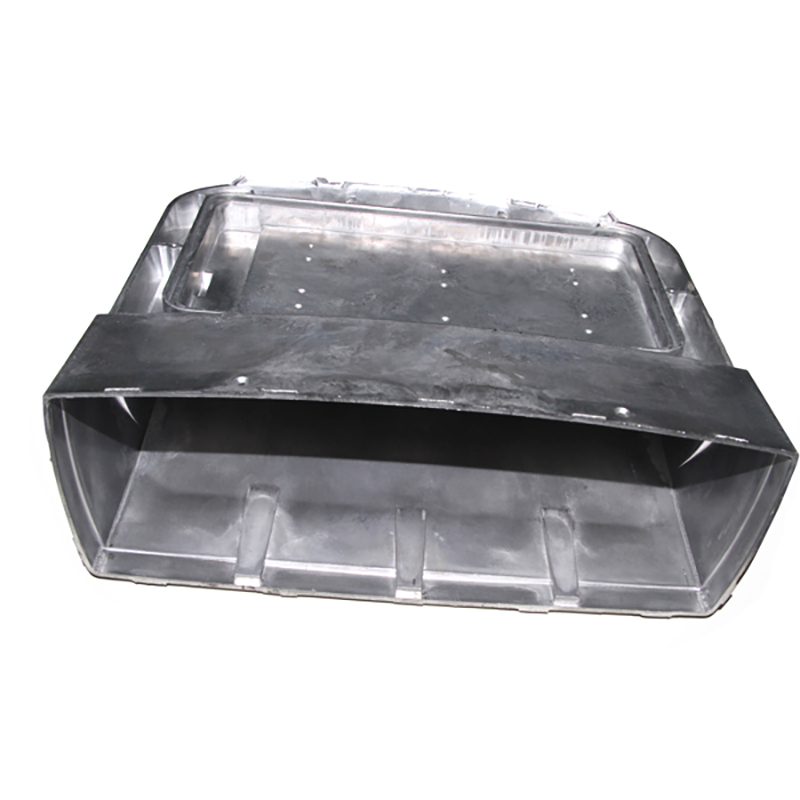

Good Quality Zinc Die Casting Parts - Die Casting Mechanical Parts – Anebon

Technical Information on Aluminum Die Casting Auto Parts

| Siz Range | Not normally over 2.7feet square |

| Parts Weight | 0.01pounds to 14 pounds |

| Setup Cost | New die casting tooling is free |

| Tolerances | 0.02inch,add0.01inch to 0.015inch across parting line up to part size |

| Die Casting Finish | 32~63 RMS |

| Minium Draft | normally 1° |

| Billet | normally 0.04inch |

| Normal Minimum Section Thickness | 0.060inch for small parts;0.090inch for medium parts |

| Ordering Quantity | For first trial order: not less than 100pcs;Usually 1,000pcs or more. |

| Normal Leadtime | Tooling: 4~12 weeks update part size;Samples: one week if no finish and CNC machining required;Production:2~3weeks |

FAQs

ISO 9001:2015 Certified Factory OEM Machined Clutch Housing Aluminum Die Casting Auto Parts

1. What service can you offer?

We can offer one- stop solution for Aluminum Die Casting Auto Parts from tool engineering, designing & developing, casting, machining, finishing, assembling, packing and shipping.

2. How to custom Aluminum Die Casting Auto Parts?

- Customers send the IGS/STEP drawings or sample to us for offer;

- Will talk about the details to meet castabilities;

- After customer`s acceptance on our prices, we will send our 3D molding drawing for approval;

- After approving the 3D molding drawing, we will start the production of the tooling/mold after the deposit of mold/tooling cost paid;

- After mold/tooling finished, will send the samples for customer`s check;

- After samples approved, will prepare the production on trial order after customer`s payment for the balance for the mold/tooling cost.

Write your message here and send it to us