1. Z-direction kayan aiki saitin na machining cibiyar

Gabaɗaya akwai hanyoyi guda uku don saitin kayan aikin-direction na cibiyoyin injuna:

1) Hanyar saitin kayan aiki akan injin 1

Wannan hanyar saitin kayan aiki shine don ƙayyade alaƙar matsayi tsakanin kowane kayan aiki da kayan aiki a cikin tsarin daidaita kayan aikin injin ta hanyar saitin kayan aiki a lokacin.CNC machining sassakumaCNC juya sassa.Matakan aikinsa na musamman sune kamar haka.

(1) Kwatanta tsayin kayan aiki, gano kayan aiki mafi tsayi azaman kayan aikin tunani, aiwatar da saitin kayan aikin Z-direction, da amfani da ƙimar saitin kayan aiki (C) a wannan lokacin azaman ƙimar Z na tsarin daidaitawa na workpiece, da H03= 0 a wannan lokacin.

(2) Shigar da kayan aikin T01 da T02 a kan sandar bi da bi, kuma ƙayyade ƙimar A da B a matsayin ƙimar diyya tsawon ta hanyar saitin kayan aiki.(Wannan hanyar ba ta auna diyya ta kayan aiki kai tsaye ba, amma ta bambanta da hanyar 3 da aka ƙaddara ta saitin kayan aiki na jeri.)

(3) Cika ƙayyadaddun ƙimar diyya mai tsayi (tsawon kayan aiki mafi tsayi banda sauran tsawon kayan aiki) cikin shafin saiti.G43 da G44 sun ƙaddara alamun tabbatacce da korau a cikin shirin, kuma a wannan lokacin G44H - gabaɗaya ke wakilta.Lokacin amfani da G43, tsayin ramuwa mara kyau ne.

Wannan hanyar saitin kayan aiki yana da ingantaccen saitin kayan aiki da daidaito, da ƙarancin saka hannun jari, amma bai dace ba don rubuta takaddun tsari, wanda ke da wani tasiri akan ƙungiyar samarwa.

2) Hanyar saitin kayan aikin kan injin 2

Takamaiman matakan aiki na wannan hanyar saitin kayan aiki sune kamar haka:

(1) Saitin daidaita alkiblar XY iri ɗaya ne kamar da, shigar da ƙimar kashewa a cikin abun XY a G54, sannan saita abu Z zuwa sifili.

(2) Sauya T1 da aka yi amfani da shi don sarrafawa tare da babban shaft, yi amfani da ma'auni na toshe don daidaita hanyar Z, karanta darajar Z1 na tsarin daidaitawa na kayan aikin injin bayan daɗaɗɗen ya dace, kuma cika tsawon ƙimar diyya H1 bayan. cire tsayin ma'aunin toshe.

(3) Shigar da T2 akan babban shaft, daidaita shi tare da ma'aunin toshe, karanta Z2, cire tsayin ma'aunin toshe kuma cika H2.

(4) Ta hanyar kwatanci, yi amfani da ma'aunin toshe don daidaita duk jikin kayan aiki, da cika Hi bayan cire tsayin ma'aunin toshe.

(5) Lokacin yin shirye-shirye, yi amfani da hanyoyi masu zuwa don ramawa:

T1;

G91 G30 Z0;

M06;

G43 H1;

G90 G54 G00 X0 Y0;

Z100;

…(Mai zuwa shine sarrafa kayan aiki na kayan aiki na No. 1 har zuwa ƙarshe)

T2;

G91 G30 Z0;

M06;

G43 H2;

G90 G54 G00 X0 Y0;

Z100;

…(Dukkan abubuwan sarrafawa na wuka No.2)

…M5;

M30;

3) Saitin kayan aikin kashe-kashe + saitin kayan aikin kan na'ura

Wannan hanyar saitin kayan aiki shine don amfani da mai saiti na kayan aiki don auna daidai girman axial da radial na kowane kayan aiki a waje da kayan aikin injin, ƙayyade tsawon ƙimar diyya na kowane kayan aiki, sannan amfani da kayan aiki mafi tsayi akan kayan injin don aiwatar da Z To. kayan aiki saitin, ƙayyade workpiece daidaita tsarin.

Wannan hanyar saitin kayan aiki yana da babban saitin kayan aiki daidai da inganci, kuma yana dacewa da shirye-shiryen takaddun tsari da ƙungiyar samarwa, amma saka hannun jari yana da girma.

2. Shigar da bayanan saitin kayan aiki

(1) Bayanan saitin kayan aiki da aka samu bisa ga ayyukan da ke sama, wato, ƙimar X, Y, da Z na asalin tsarin haɗin gwiwar shirye-shirye a cikin tsarin haɗin gwiwar injin, dole ne a shigar da su da hannu cikin G54 ~ G59 don ajiya.Matakan aikin sune kamar haka:

①Latsa【MENU OFFSET】 maɓalli.

② Danna maɓallin siginan kwamfuta don matsawa zuwaCNC niƙa sassakumaCNC juya sassatsarin daidaitawa G54~G59 don sarrafa shi.

③Latsa【X】 maɓalli don shigar da ƙimar daidaitawar X.

Latsa【INPUT】 maɓalli.

Danna maɓalli【Y】 don shigar da ƙimar daidaitawar Y.

Latsa【INPUT】 maɓalli.

⑦Latsa【Z】 maɓalli don shigar da ƙimar daidaitawar Z.

Latsa【INPUT】 maɓalli.

(2) Ƙimar diyya ta kayan aiki gabaɗaya ita ce shigarwa cikin kayan aikin injin kafin shirin gyara kuskure ta MDI (shigarwar bayanai ta hannu).Matakan aiki na gaba ɗaya sune kamar haka:

①Latsa【MENU OFFSET】 maɓalli.

② Danna maɓallin motsi na siginan kwamfuta zuwa lambar ramuwa.

③ Ƙimar shigar da diyya.

Latsa【INPUT】 maɓalli.

3. Hanyar yanke gwaji don saitin wuka

Hanyar yankan gwaji hanya ce mai sauƙi na saitin kayan aiki, amma zai bar alamomi akan kayan aikin, kuma daidaiton saitin kayan aikin yana da ƙasa.Ya dace da saitin kayan aiki a lokacin m machining na sassa.Hanyar saitin kayan aiki iri ɗaya ne da na mai gano gefen injina.

4. Lever dial dial ma'auni kayan aiki saitin

Daidaitaccen saitin kayan aiki na alamar bugun bugun lefa yana da girma, amma wannan hanyar aiki tana da wahala kuma ingancin yana da ƙasa.Ya dace da saitin kayan aiki na ramin ƙarewa (surface), amma bai dace da ramin machining ba.

Hanyar saitin kayan aiki shine kamar haka: Yi amfani da tushen agogon maganadisu don jawo alamar bugun bugun lefa zuwa sandar cibiyar injin, kuma sanya ma'aunin kai kusa da bangon rami (ko saman silinda).A cikin kuskuren, kamar 0.02, ana iya la'akari da cewa cibiyar jujjuyawar igiya ta zo daidai da tsakiyar ramin da aka auna a wannan lokacin, kuma shigar da ƙimar daidaitawar X da Y a cikin tsarin daidaita na'ura a wannan lokacin zuwa G54.

5. Saitin kayan aiki a hanyar Z

Idan akai la'akari da samar da saitin kayan aiki, saman saman kayan aikin yawanci ana ɗaukar shi azaman asalin tsarin Z na tsarin daidaitawa na workpiece.Lokacin da saman saman ɓangaren yana da ɗan ƙanƙara kuma ba za a iya amfani dashi azaman saitin kayan aiki ba, ana iya amfani da vise ko workbench azaman tushen tushen tsarin tsarin aikin aikin, sa'an nan kuma an gyara tsayin aikin. zuwa sama a cikin G54 ko tsawaita tsarin daidaitawa don cika. Saitin kayan aikin na'ura na Z-direction ya haɗa da saitin kayan aikin aunawa na Z-direction, saitin kayan aikin toshe kayan aiki da saitin hanyar yankan gwaji da sauran hanyoyin.

6. Saitin kayan aiki ta hanyar auna ma'aunin Z-direction

Daidaitaccen saitin kayan aiki na ma'aunin ma'aunin Z-direction yana da girma, musamman lokacin da aka saita kayan aikin da yawa akan injin a cikin cibiyar injin milling, ingantaccen saitin kayan aikin yana da girma, saka hannun jari yana da ƙarami, kuma ya dace da sashi guda ɗaya. sarrafawa.

1) Saitin kayan aiki na Z-direction yayin aikin kayan aiki guda ɗaya na cibiyar injin

Kayan aiki guda ɗaya a cikin cibiyar sarrafa kayan aiki yana kama da matsalar cewa babu tsayin diyya don saitin kayan aiki akan injin milling na CNC.Matakan sune kamar haka:

(1) Sauya kayan aikin da za a yi amfani da shi don sarrafawa;

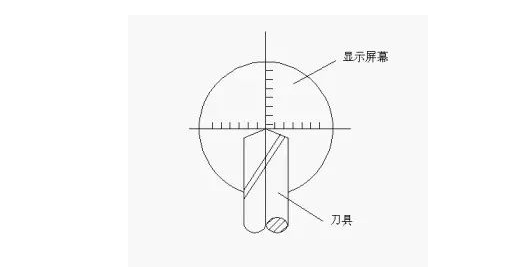

(2) Matsar da kayan aiki zuwa saman workpiece, auna nisa tsakanin workpiece da kayan aiki tare da Z-direction kayan aiki aunawa, da kuma rikodin Z-axis karanta Z na halin yanzu inji kayan aiki (na inji) daidaita tsarin;

(3) Cire ƙimar Z daga tsayin kayan aunawa na Z-direction a wannan lokacin (kamar 50.03mm), sannan cika ƙimar da aka auna a cikin abin Z na OFFSETSETTING–> tsarin daidaitawa–> G54;

(4) Gudun G90 G54G0 X0 Y0 Z100;duba ko jeri daidai ne

Lokacin aikawa: Janairu-09-2023