Menene sassan eccentric?

Sassan eccentric sassa ne na injina waɗanda ke da kusurwar juyawa ta tsakiya ko kuma siffa mara kyau wacce ke sa su jujjuya ta hanyar da ba ta dace ba.Ana amfani da waɗannan sassa sau da yawa a cikin injina da tsarin injina inda ake buƙatar takamaiman motsi da sarrafawa.

Misali ɗaya na gama gari na ɓangaren eccentric shine cam ɗin eccentric, wanda shine faifan madauwari tare da fitowa a saman sa wanda ke sa shi motsawa ta hanyar da ba ta dace ba yayin da yake juyawa.Har ila yau, sassan sassa na iya nufin duk wani abu da aka ƙera da gangan don juyawa daga tsakiya, kamar ƙayyadaddun ƙugiya tare da rarraba mara daidaituwa.

Ana amfani da sassa masu ƙazafi sau da yawa a aikace-aikace kamar injuna, famfo, da tsarin isar da saƙo inda ake buƙatar takamaiman motsi da sarrafawa.Za su iya taimakawa don rage girgiza, haɓaka aiki, da ƙara tsawon rayuwar injin.

Gabatarwa

A cikin tsarin watsawa, sassan eccentric kamar eccentric workpieces ko crankshafts ana amfani da su gabaɗaya don kammala aikin jujjuyawar juna tsakanin motsin jujjuyawa da motsi mai maimaitawa, don haka ana amfani da sassan eccentric a watsawar injina.Matsayin fasahar sarrafa sassa na eccentric (musamman manyan kayan aikin eccentric) na iya nuna iyawar fasahar injina na kamfani.

Eccentric workpieces suna taka muhimmiyar rawa a ainihin samarwa da rayuwa.A cikin watsawar inji, jujjuya motsin motsi zuwa motsin layi ko jujjuya motsin linzamin kwamfuta zuwa motsin jujjuyawar gabaɗaya ana cika shi ta hanyar kayan aiki na eccentric ko crankshafts.Misali, famfon mai mai mai a cikin akwatin dunƙule yana motsa shi ta hanyar madaidaicin shaft, kuma motsin motsi na crankshaft na mota da tarakta ana motsa shi ta hanyar motsi madaidaiciya na piston.

Ƙwararrun sharuddan / sunaye

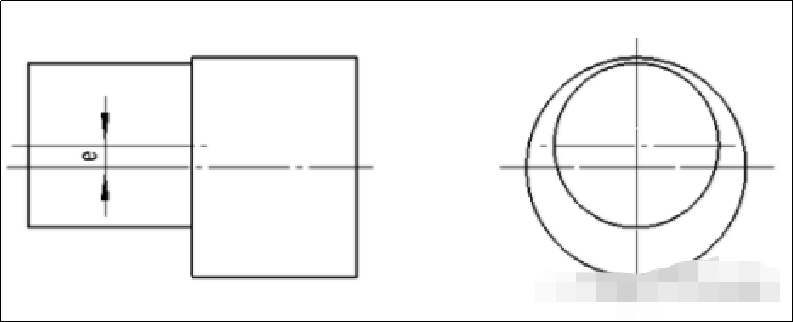

1) Eccentric workpiece

The workpiece wanda gatari na waje da'ira da m da'irar ko m da'irar da ciki rami ne a layi daya amma ba daidai ba ya zama eccentric workpiece.

2) Eccentric shaft

The workpiece wanda gatari na waje da'ira da m da'irar ne a layi daya da kuma ba daidai ba ne ake kira eccentric shaft.

3) Eccentric hannun riga

The workpiece wanda gatari na waje da'irar da na ciki rami suke a layi daya amma ba daidai ba ne ake kira eccentric hannun riga.

4) Rashin daidaituwa

A cikin kayan aikin eccentric, nisa tsakanin axis na sashin eccentric da axis na sashin tunani ana kiransa eccentricity.

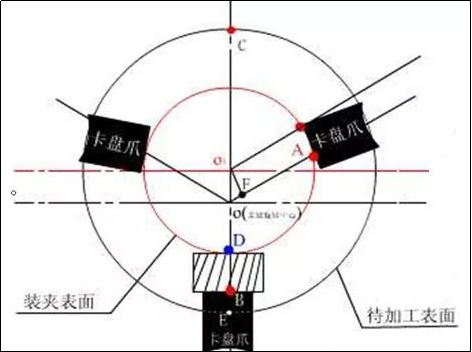

Chuck mai kaifin baki uku ya dace da kayan aikin eccentric waɗanda ba sa buƙatar jujjuya madaidaicin juzu'i, ƙaramin nesa mai nisa, da ɗan gajeren tsayi.Lokacin juyawa, eccentricity na workpiece yana da garantin kauri na gasket da aka sanya akan muƙamuƙi.

Kodayake hanyoyin sarrafa gargajiya na eccentricCNC machining sassakuma ingantacciyar hanyar jujjuyawar muƙamuƙi uku na iya kammala aikin sarrafa sassan kayan aiki na eccentric, lahani na aiki mai wahala, ƙarancin inganci, musanyawa da daidaito suna da wahala a ba da garanti.Na zamani high-inganci dahigh-daidaici machiningConcepts ba za su iya jure wa.

Ƙa'ida, Hanya da Mahimman Bayanan Kulawa na Ƙarfafa Ƙaƙƙarfan Jaw Chuck Uku

Ka'idar eccentricity na muƙamuƙi uku: daidaita tsakiyar jujjuyawar farfajiyar aikin da za a sarrafa don zama mai da hankali tare da axis na sandar kayan aikin injin.Daidaita geometric centroid na ɓangaren matsewa zuwa nisa daga igiyar igiya daidai da eccentricity.

Lissafin kauri na Gasket (farko, ƙarshe) l dabarar lissafin kauri na Gasket: x=1.5e+k inda:

e-workpiece eccentricity, mm;

k——Ƙimar gyare-gyare (wanda aka samu bayan gwajin gwajin, wato, k≈1.5△e), mm;

△e—kuskuren tsakanin ma'aunin da aka auna da ma'aunin da ake buƙata bayan gwajin gwajin (watau △e=ee auna), mm;

e ma'auni - ma'auni na eccentricity, mm;

Misali 1

Juya workpiece tare da eccentricity na 3mm, idan kauri na gasket aka juya tare da wani gwaji selection, da ma'auni eccentricity ne 3.12mm, da kuma daidai darajar kauri na gasket aka samu.l Magani: Kaurin gasket ɗin gwaji shine:

X=1.5e=1.5×3mm=4.5mm

△e=(3-3.12)mm=-0.12mm

K=1.5△e=1.5×(-0.12)mm=-0.18mm

Bisa ga dabara: x=1.5e+k=(4.5-0.18) mm=4.32mm

Madaidaicin ƙimar gasket kauri shine 4.32mm.

Misali 2

Ana amfani da gasket tare da kauri na 10mm don kunna kayan aikin eccentric akan kushin muƙamuƙi na chuck mai kaifin baki uku.Bayan juyawa, ana auna girman girman aikin don zama 0.65mm ƙarami fiye da buƙatun ƙira.Nemo madaidaicin ƙimar kaurin gasket.

Kuskuren eccentricity da aka sani △e=0.65mm

Kimanin kauri na gasket: X gwajin = 1.5e = 10mm

K=1.5△e=1.5×0.65mm=0.975mm

Bisa ga dabara: x=1.5e+k=(10+0.975)mm=10.975mm

Madaidaicin ƙimar gasket kauri shine 10.975mm.

Lalacewar juyar da muƙamuƙi uku

Juyin muƙamuƙi uku, wanda kuma aka sani da eccentric chucking, wani tsari ne na juyi inda aka gudanar da aikin aiki a cikin chuck ɗin da ke da muƙamuƙi uku waɗanda ba a tsakiya tare da axis na chuck.Madadin haka, an saita ɗayan jaws a tsakiyar tsakiya, ƙirƙirar eccentricrotation na aikin aikin.

Duk da yake jujjuyawar muƙamuƙi guda uku yana da wasu fa'idodi, kamar ikon juzu'i masu siffa ba bisa ka'ida ba da rage buƙatar kayan aiki na musamman, shima yana da rashin amfani, gami da:

1. Tsare-tsare mara kyau: Saboda aikin aikin yana tsaye a tsakiya, yana iya zama da wahala a daidaita shi don ainihin ayyukan injina.Wannan na iya haifar da ɓangarorin da ba su da juriya ko kuma ba su da daidaito.

2. Rage ikon riƙewa: The kashe-tsakiya jaw yana da ƙasa da gripping iko fiye da the2other biyu jaws, wanda zai iya haifar da a kasa amintacce riƙe a kan workpiece.Wannan na iya haifar da kayan aiki don motsawa ko zamewa yayin aikin injiniya, wanda ke haifar da yanke mara daidai kuma yanayi mai haɗari.

3. Ƙara kayan aiki: Saboda workpiece ba a tsakiya ba, kayan aikin yankan na iya samun rashin daidaituwa mara kyau, wanda zai iya haifar da gajeren rayuwar kayan aiki da ƙarin farashi don maye gurbin kayan aiki.

4. Iyakantattun sassa na sassa: Eccentric chucking gabaɗaya ya fi dacewa da ƙananan sassa zuwa 4.matsakaici, dacnc juya parttare da siffar yau da kullum.Maiyuwa bazai dace da manyan sassa ko hadaddun sassa ba, saboda muƙamuƙi na tsakiya bazai samar da isasshen tallafi ba.

5. Tsawon lokacin saitin: Saita chuck don jujjuyawar eccentric na iya zama mafi ɗaukar lokaci fiye da kafa daidaitaccen chuck, saboda yana buƙatar sanyawa a hankali na muƙamuƙi na tsakiya don cimma ƙimar da ake so.

A cikin CNC Lathe, ana ƙirƙira sassan eccentric ta hanyar sarrafa ɓangaren akan alathe ta amfani da ƙugiya ta musamman ko abin ɗamara wanda ke riƙe da sashin tsakiya.

Waɗannan su ne matakan gabaɗayan don ƙirƙirar sassa na eccentric a cikin lathe CNC:

1. Zabi madaidaicin eccentric chuck ko kayan aiki wanda ya dace da aikin aiki kuma yana ba da izini

eccentricity da ake so.

2. Saita lathe tare da chuck ko kayan aiki da kuma hawan kayan aikin amintacce.

3. Yi amfani da software na lathe don saita saiti don ƙimar da ake so.

4. Shirya na'ura na CNC don yanke sashin bisa ga tsarin da ake so, tabbatar da yin lissafin biya a cikin hanyar yanke.

5. Gudanar da shirin gwaji don tabbatar da cewa an yanke sashin daidai kuma cewa girman kai yana cikin juriyar da ake so.

6. Yi duk wani gyare-gyare mai mahimmanci ga shirin yanke ko saitin don cimma sakamakon da ake so.

7. Ci gaba da yanke sashin har sai an kammala shi, tabbatar da duba lokaci-lokaci da kuma yin gyare-gyare masu mahimmanci.

Gabaɗaya, ƙirƙirar ɓangarori masu ma'ana a cikin lathe CNC yana buƙatar tsarawa a hankali da daidaito don tabbatar da cewa samfurin ƙarshe ya cika ƙayyadaddun abubuwan da ake so.

Abubuwan da ke sama ƙungiyar Anebon ne kawai ke bayarwa, dole ne a bincika cin zarafi

Anbonwani kamfani ne na masana'antu da ke Shenzhen, China wanda ya ƙware wajen samar da sabis na injin CNC na musamman.Kamfanin yana ba da sabis na masana'antu da dama, ciki har da CNC milling, juyawa, hakowa, da niƙa, da kuma jiyya da sabis na taro.

Anebon yana da gogewa da aiki tare da kayan aiki iri-iri, gami da aluminum, tagulla, bakin karfe, titanium, da robobi, kuma yana iya samar da sassa tare da hadaddun geometries da matsananciyar haƙuri.Kamfanin yana amfani da kayan aiki na ci gaba, irin su 3-axis da 5-axis CNC inji, da kayan aikin dubawa, don tabbatar da samfurori masu inganci.

Baya ga ayyukan injina na CNC, Anebon kuma yana ba da sabis na samfuri, yana bawa abokan ciniki damar gwadawa da kuma daidaita ƙirar su cikin sauri kafin motsawa zuwa samarwa da yawa.Kamfanin yana alfahari da sadaukar da kai ga sabis na abokin ciniki da inganci, kuma yana aiki tare da abokan ciniki don tabbatar da takamaiman bukatunsu da buƙatun su.

Lokacin aikawa: Fabrairu-27-2023