1. Z-direction tool setting of machining center

There are generally three methods for Z-direction tool setting of machining centers:

1) On-machine tool setting method 1

This tool setting method is to sequentially determine the mutual positional relationship between each tool and the workpiece in the machine tool coordinate system through tool setting during CNC machining parts and CNC turning parts. Its specific operation steps are as follows.

(1) Compare the tool lengths, find out the longest tool as the reference tool, perform Z-direction tool setting, and use the tool setting value (C) at this time as the Z value of the workpiece coordinate system, and H03=0 at this time.

(2) Install the tools T01 and T02 on the spindle in turn, and determine the values of A and B as the length compensation value through tool setting. (This method does not directly measure tool compensation, but is different from method 3 determined by sequential tool setting.)

(3) Fill in the determined length compensation value (the longest tool length minus the remaining tool length) into the setting page. The positive and negative signs are determined by G43 and G44 in the program, and at this time it is generally represented by G44H—. When using G43, the length compensation is a negative value.

This tool setting method has high tool setting efficiency and precision, and less investment, but it is inconvenient to write process documents, which has a certain impact on production organization.

2) On-machine tool setting method 2

The specific operation steps of this tool setting method are as follows:

(1) The XY direction alignment setting is the same as before, input the offset value in the XY item in G54, and set the Z item to zero.

(2) Replace the T1 used for processing with the main shaft, use the block gauge to align the Z direction, read the Z value Z1 of the machine tool coordinate system after the tightness is appropriate, and fill in the length compensation value H1 after deducting the height of the block gauge.

(3) Install T2 on the main shaft, align it with a block gauge, read Z2, deduct the height of the block gauge and fill in H2.

(4) By analogy, use block gauges to align all tool bodies, and fill in Hi after deducting the height of the block gauges.

(5) When programming, use the following methods to compensate:

T1;

G91 G30 Z0;

M06;

G43 H1;

G90 G54 G00 X0 Y0;

Z100;

…(The following is the tool-pass processing of No. 1 tool until the end)

T2;

G91 G30 Z0;

M06;

G43 H2;

G90 G54 G00 X0 Y0;

Z100;

…(All processing contents of No.2 knife)

…M5;

M30;

3) Off-machine tool presetting + on-machine tool setting

This method of tool setting is to use the tool presetter to accurately measure the axial and radial dimensions of each tool outside the machine tool, determine the length compensation value of each tool, and then use the longest tool on the machine tool to perform Z To tool setting, determine the workpiece coordinate system.

This tool setting method has high tool setting accuracy and efficiency, and is convenient for the preparation of process documents and production organization, but the investment is relatively large.

2. Input of tool setting data

(1) The tool setting data obtained according to the above operations, that is, the X, Y, and Z values of the origin of the programming coordinate system in the machine coordinate system, must be manually input into G54~G59 for storage. The operation steps are as follows:

①Press【MENU OFFSET】key.

②Press the cursor key to move to the CNC milling parts and CNC turning parts coordinate system G54~G59 to be processed.

③Press【X】key to input X coordinate value.

④Press【INPUT】key.

⑤Press【Y】key to input Y coordinate value.

⑥Press【INPUT】key.

⑦Press【Z】key to input Z coordinate value.

⑧Press【INPUT】key.

(2) The tool compensation value is generally input into the machine tool before program debugging by MDI (manual data input). The general operation steps are as follows:

①Press【MENU OFFSET】key.

②Press the cursor movement key to the compensation number.

③Input compensation value.

④Press【INPUT】key.

3. Trial cutting method for knife setting

Trial cutting method is a simple tool setting method, but it will leave marks on the workpiece, and the tool setting accuracy is low. It is suitable for tool setting during rough machining of parts. Its tool setting method is the same as that of the mechanical edge finder.

4. Lever dial gauge tool setting

The tool setting accuracy of the lever dial indicator is high, but this operation method is cumbersome and the efficiency is low. It is suitable for the tool setting of the finishing hole (surface), but it is not suitable for the rough machining hole.

The tool setting method is as follows: use the magnetic watch base to attract the lever dial indicator to the spindle of the machining center, and make the gauge head close to the hole wall (or cylindrical surface). Within the error, such as 0.02, it can be considered that the rotation center of the spindle coincides with the center of the measured hole at this time, and input the X and Y coordinate values in the machine coordinate system at this time into G54.

5. Tool setting in Z direction

Considering the manufacturability of tool setting, the upper surface of the workpiece is usually taken as the origin of the Z direction of the workpiece coordinate system. When the upper surface of the part is relatively rough and cannot be used as the tool setting reference, the vise or workbench can also be used as the origin of the Z direction of the workpiece coordinate system, and then the height of the workpiece is corrected upward in the G54 or extended coordinate system to fill in. Z-direction machine tool setting mainly includes Z-direction measuring instrument tool setting, tool setting block tool setting and trial cutting method tool setting and other methods.

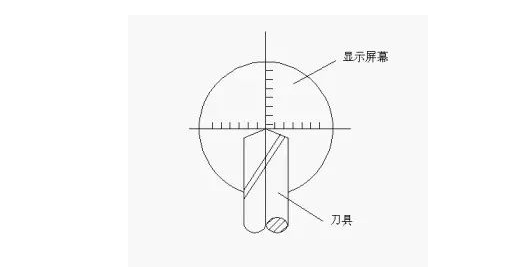

6. Tool setting by Z-direction measuring instrument

The tool setting accuracy of the Z-direction measuring instrument is high, especially when multiple tools are set on the machine in the milling machining center, the tool setting efficiency is high, the investment is small, and it is suitable for single-piece part processing.

1) Z-direction tool setting during single-tool machining of the machining center

Single-tool machining in a machining center is similar to the problem that there is no length compensation for tool setting on a CNC milling machine. The steps are as follows:

(1) Replace the tool that will be used for processing;

(2) Move the tool to the top of the workpiece, measure the distance between the workpiece and the tool with a Z-direction measuring instrument, and record the Z-axis reading Z of the current machine tool (mechanical) coordinate system;

(3) Subtract the Z value from the height of the Z-direction measuring instrument at this time (such as 50.03mm), and then fill the measured value into the Z item of OFFSETSETTING–>coordinate system–>G54;

(4) Run G90 G54G0 X0 Y0 Z100; check whether the alignment is correct

Post time: Jan-09-2023