The simple point of CNC prototype model planning is to make one or several first based on product appearance drawings or structural drawings without opening the mold to check the functional model of the appearance or structure.

The evolution of prototype planning: The early prototypes were constrained by various conditions. The first manifestation was that most of their work was done by hand, which made it difficult to strictly meet the scale requirements of appearance and structural drawings. , So its function of checking appearance or structural rationality is also greatly reduced. Prototype model planning follows the advancement of science and technology, and the rapid development of CAD and CAM skills provides better technical support for prototype production, making it possible to make the prototype accurate. On the other hand, with the increasingly fierce social competition, the speed of product development has increasingly become the primary contradiction of the competition, and prototype production can effectively improve the speed of product development. It is under this situation that the prototype manufacturing industry is fully exposed. Become a relatively independent profession and flourish. aluminum part

Classification of prototype model planning:

Prototype model planning is divided into production methods: Prototypes can be divided into technical prototypes and CNC prototypes according to the production methods:

(1) Craftsmanship: Its primary workload is completed by hand.

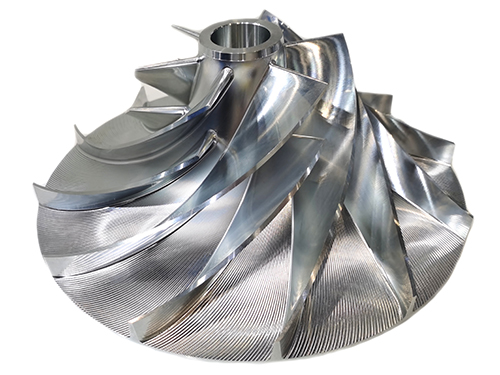

(2) Numerical control prototype: its primary workload is completed by CNC machine tools, and depending on the equipment used, it can be divided into laser rapid prototyping (RP, Rapid Prototyping) prototypes and machining center (CNC) prototypes. anodizing aluminum part

A: RP prototype: prototype model planning is primarily a prototype produced with laser rapid prototyping skills.

B: CNC prototype: the first is the prototype produced by the machining center.

RP prototypes have their own advantages compared with CNC prototypes: the strengths of RP prototypes are mainly reflected in its rapidity, but it is mainly formed by stacking skills, so RP prototypes are generally relatively rough and have certain requirements for the wall thickness of the product, for example, The wall thickness is too thin to produce. machined part

Anebon Metal Products Limited can provide CNC machining, die casting, sheet metal machining services, please feel free to contact us.

Tel: +86-769-89802722 Email: info@anebon.com Website: www.anebon.com

Post time: Dec-30-2020