The spline shaft is a kind of mechanical transmission. The peace key, the semi-circle key and the oblique key function as the mechanical torque. The outer surface of the shaft has a longitudinal keyway, and the rotating part sleeved on the shaft also has a corresponding keyway, which can be maintained. Rotate synchronously with the axis. While rotating, some can also slide longitudinally on the shaft, such as gearbox shifting gears.

1. Function: It is a kind of mechanical transmission. The function of the peace key, the semi-circle key and the oblique key is the transmission of mechanical torque.

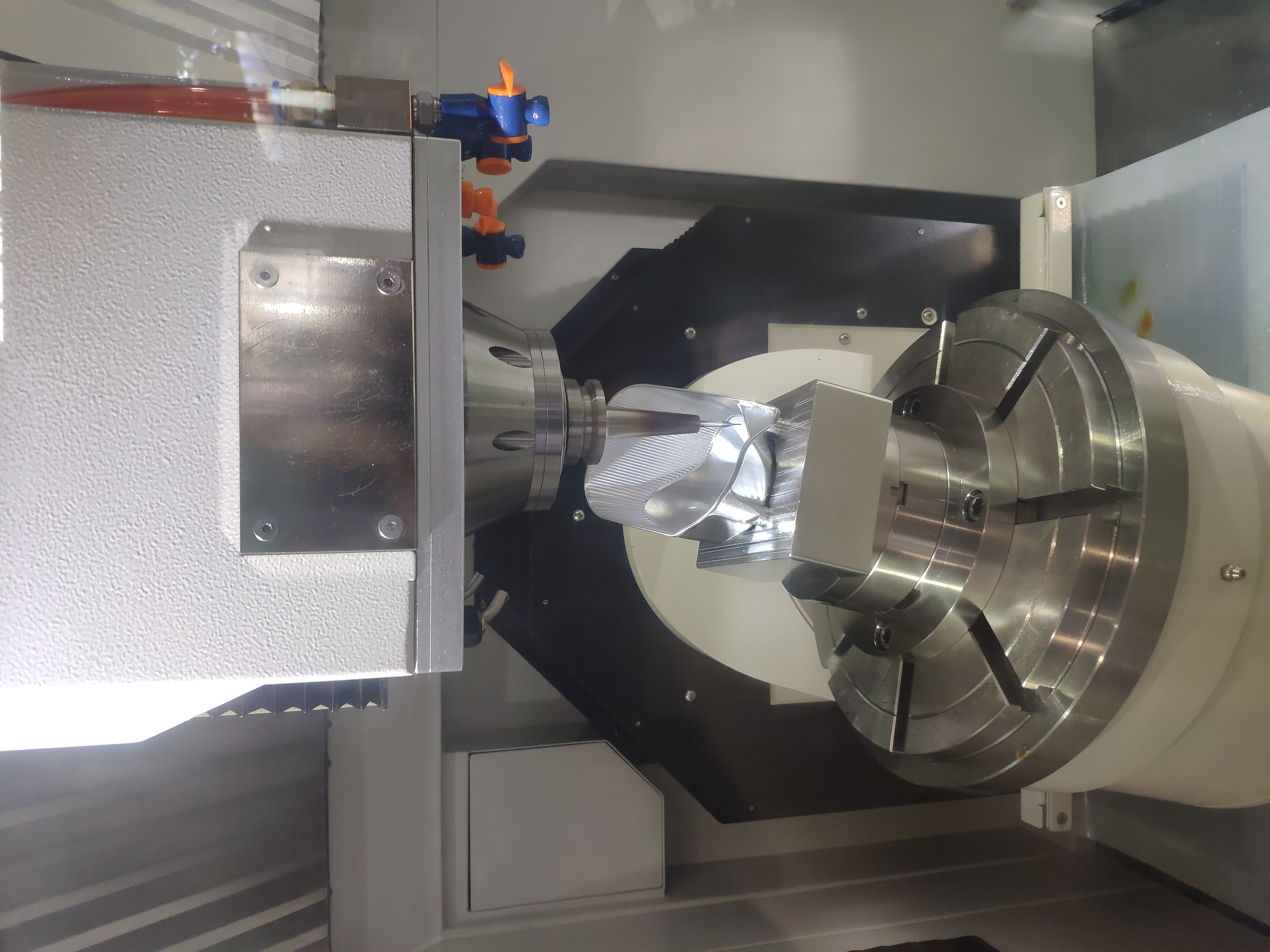

2. Structure: There is a longitudinal keyway on the outer surface of the shaft, and the rotating part sleeved on the shaft also has a corresponding keyway, which can keep rotating synchronously with the shaft. While rotating, some can also slide longitudinally on the shaft, such as gearbox shifting gears. cnc machining part

3. Application examples: in the brake and steering mechanism. There is also a retractable shaft consisting of inner and outer tubes, the outer tube having internal teeth and the inner tube having external teeth and sleeved together. In use, it can be extended and contracted in the longitudinal direction while transmitting the rotational torque. machined part

4, material: 40Cr

5. Heat treatment. Quenching surface hardness HRC45--50

Rectangular spline shaft

Rectangular spline shafts are used in a wide range of applications such as aircraft, automobiles, tractors, machine tool manufacturing, agricultural machinery and general mechanical transmissions.

Its characteristics: multi-tooth work, high bearing capacity, good neutrality, good guiding, shallow root, low stress concentration, weak shaft and hub strength, easy processing, high precision with grinding method. There are two series in the standard (light series and medium series). plastic part

Involute spline shaft

The involute spline shaft is used for large loads, high centering accuracy requirements, and large size links.

Its characteristics: the tooth profile is involute, there is radial force on the tooth when loading, it can automatically fix the heart, so that the teeth are evenly stressed, high strength and long life, the processing technology is the same as the gear, easy to obtain higher precision And interchangeability.

Processing methods

Spline processing method] rl] Spline shaft url] b] processing method is a lot. Mainly used in the cutting process such as hobbing, milling and grinding, it can also be used in the cold deformation, cold rolling and other plastic deformation processing methods.

1. Rolling method: It is processed by the spline hob on the spline shaft milling machine or hobbing machine according to the forming method. This method has high productivity and precision and is suitable for mass production.

2. Milling method: directly milling the inter-tooth profile with a special forming cutter on the universal milling machine, and milling the teeth with the indexing head. If the milling cutter is not used, the two milling cutters can also be used to simultaneously mill one tooth. On both sides, after milling by tooth, use a disc cutter to slightly trim the bottom diameter. The milling method has low productivity and precision, and is mainly used for processing spline shafts with outer diameter centering and roughing before hardening in single-piece small batch production.

3. Grinding method: Grinding spline flank and bottom diameter on a spline shaft grinding machine with a forming grinding wheel, suitable for processing hardened spline shafts or splines with higher precision, especially with inner diameter centering splines axis.

4, cold play: on a special machine. The two heads symmetrically arranged outside the circumference of the workpiece, with the indexing rotary motion of the workpiece and the axial feed for a constant speed ratio of high-speed rotation, the workpiece per revolution of 1 tooth, the forming wheel on the head is on the tooth groove of the workpiece Hammering once, under the continuous high-speed, high-energy motion hammering, the surface of the workpiece is plastically deformed into splines. The accuracy of cold punching is between milling and grinding, and the efficiency is about 5 times higher than milling. Cold hitting can also improve material utilization. The above introduction is a detailed explanation of the spline shaft processing method.

Anebon Metal Products Limited can provide CNC machining, die casting, sheet metal machining services, please feel free to contact us.

Tel: +86-769-89802722 Email: info@anebon.com Website : www.anebon.com

Post time: Aug-31-2019