Turned Parts

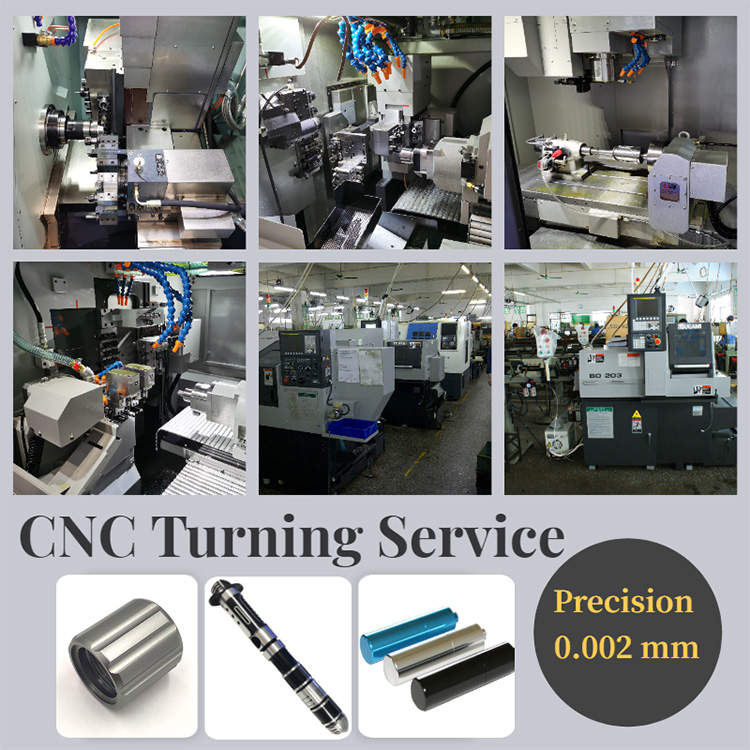

Turning center

Turning machining center: On the basis of ordinary CNC lathe, C axis and power head are added. The more advanced machine tool also has a tool magazine, which can control three coordinate axes of X, Z and C. The linkage control axis can be (X, Z), (X, C) or (Z, C). Thanks to the addition of the C-axis and the milling power head, the machining function of this CNC lathe is greatly enhanced. In addition to general turning, radial and axial milling, surface milling, and the center line are not in the center of the part. Machining to holes, etc.

Write your message here and send it to us