Aluminum - China Factory, Suppliers, Manufacturers

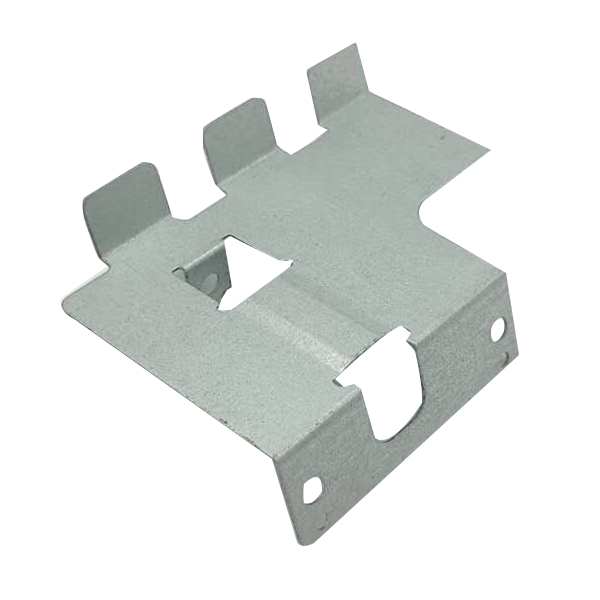

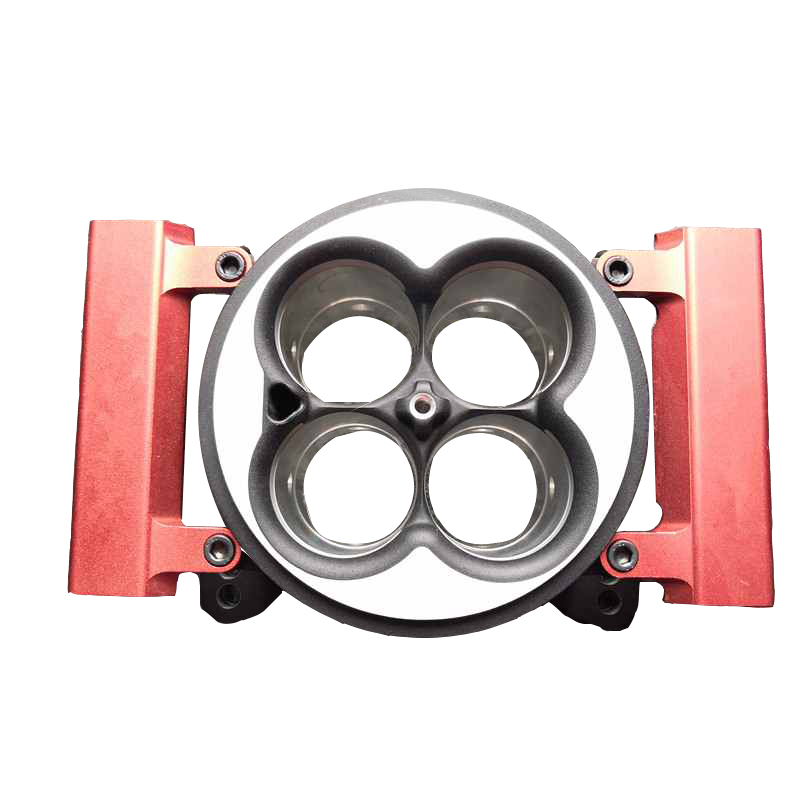

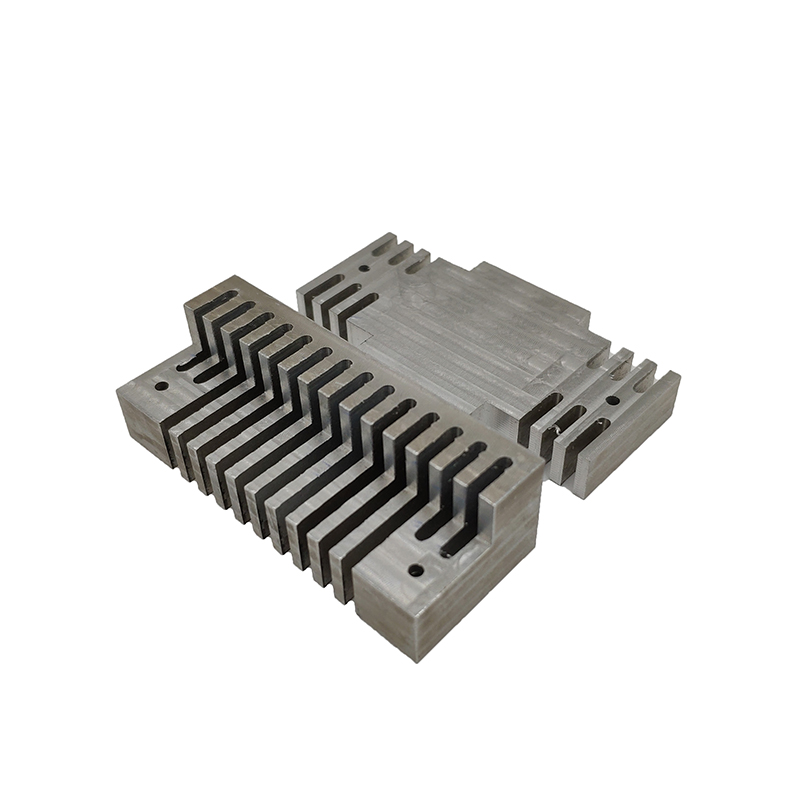

Whether you are a repeat customer or a new customer, we look back from you.We hope you can find what you want here, and if not, please contact us immediately.We pride ourselves in our superb customer service and response.Thanks for your business and support!We hope that we can become one of the largest exporters in the region, to meet the additional consumer demand for Chinese personalized products of bronze / copper / brass forgings, Anebon is committed to providing you with professional purification technology and solutions!Your inquiries is welcome and will be appreciated. Aluminum, Aluminum Cnc Machining , Cnc Fabrication Service , Medical Machining ,Aluminum Component . It is a good way to enhance our products and solutions and repair. Our mission will be to build creative solutions to consumers with a great experience for Professional China Personal Customization cnc aluminum parts,cnc machinery parts,brass turned parts,cheap metal fabrication, Aluminum CNC Turning Part, In case you are looking for a high quality, quickly delivery, best just after assistance and good value supplier in China for long-term organization connection, we're going to be your most effective choice. The product will supply to all over the world, such as Europe, America, Australia,Nicaragua, Sacramento,Mexico, Austria.We have now a specialist, efficiency staff to provide good quality company for our consumer. We normally follow the tenet of customer-oriented, details-focused for Factory For Customized Precision Metal Aluminum Plastic Machined/Machinery/Machine CNC Turnning/Milling/Welding/Stamping Machining Parts/die casting service for Motorcycle Auto Spare Parts, We sincerely welcome buddies to negotiate business enterprise and start cooperation with us. We hope to join hands with good friends in different industries to produce a brilliant long term.

Related Products