Die Casting Service

Die casting has been a specialty of Anebon for over 10 years. Our aluminum casting services have been helping engineers, product designers and architects bring their designs to life with state of the art part designs and reliable quality. Given our experience in the industry, together with our state-of-the-art equipment, our expert manufacturing and quality engineers, and production staff, you are guaranteed quality manufacturing of your parts and products at an economical rate with Anebon.We’re an ISO 9001:2015 certified die casting manufacturer that specializes in die casting services for the world’s leading industries and companies. Our equipment covers almost all die casting engineering, designing and development needs your company may require.

Casting equipment and molds are expensive, so the die casting process is generally only used to mass produce a large number of products. It is relatively easy to manufacture die-cast parts, which generally requires only four major steps, with a single cost increment being low. Die casting is particularly suitable for the manufacture of a large number of small and medium-sized castings, so die casting is the most widely used of various casting processes. Compared to other casting techniques, the die-cast surface is flatter and has a higher dimensional consistency.

What is Die Casting?

Die casting is a metal casting process characterized by the use of a mold cavity to apply high pressure to the molten metal. Molds are usually machined from higher strength alloys, some of which are similar to injection molding. Most die castings are iron-free, such as zinc, copper, aluminum, magnesium, lead, tin, and lead-tin alloys and other alloys. Depending on the type of die casting, a cold chamber die casting machine or a hot chamber die casting machine is required.

Characteristics

Die casting is a casting method in which a molten alloy liquid is poured into a pressure chamber, a cavity of a steel mold is filled at a high speed, and the alloy liquid is solidified under pressure to form a casting. The main features of die casting that distinguish it from other casting methods are high pressure and high speed.

1. The molten metal fills the cavity under pressure and crystallizes at a higher pressure. The common pressure is 15-100 MPa.

2 . Metal liquid fills the cavity at high speed, usually at 10-50 m / s, and some can also exceed 80 m / s, (line speed through the ingate into the cavity - ingate speed), so the molten metal‘s filling time is extremely short, and the cavity can be filled in about 0.01-0.2 seconds (depending on the size of the casting).

Die-casting is a precision casting method. Die-casting parts cast by die-casting, have very small dimensional tolerances and high surface precision. In most cases, die-casting parts can be assembled without turning. Parts can also be cast directly.

What are the benefits of die casting services?

Our revolutionary die casting process offers many important benefits, including:

l Customization: It helps to achieve complex designs and forms that make it easy to customize castings to specific manufacturing processes.

l l Low cost

l l l High effiency

l l l l Multi-functional and corrosion-resistant

As an die-casting manufacturer, Anebon Die Casting offers complete, comprehensive assembly and testing of all die-cast parts and products. Whether you are interested in special components such as aluminum die casting or vacuum die casting, or just want to be a prototype of a new part, you can get a full service experience in our factory.

Material

The metal we used for die casting mainly include zinc, copper, aluminum, magnesium, lead, tin, and lead-tin alloys, etc. Although cast iron is rare, it is also feasible. The characteristics of various metals during die casting are as follows:

• Zinc: The most easily die-cast metal, economical when manufacturing small parts, easy to coat, high compressive strength, high plasticity, and long casting life.

• Aluminum: High quality, complex manufacturing and thin-walled castings with high dimensional stability, high corrosion resistance, good mechanical properties, high thermal conductivity and electrical conductivity, and high strength at high temperatures.

• Magnesium: Easy to machine, high strength to weight ratio, the lightest of the commonly used die-cast metals.

• Copper: High hardness and strong corrosion resistance. The most commonly used die-cast metal has the best mechanical properties, anti-wear and strength close to steel.

• Lead and tin: High density and high dimensional accuracy for special corrosion protection parts. For reasons of public health, this alloy cannot be used as a food processing and storage facility. Lead-tin-bismuth alloys (sometimes also containing a little copper) can be used to make hand-finished lettering and hot stamping in letterpress printing.

Aluminum Casting

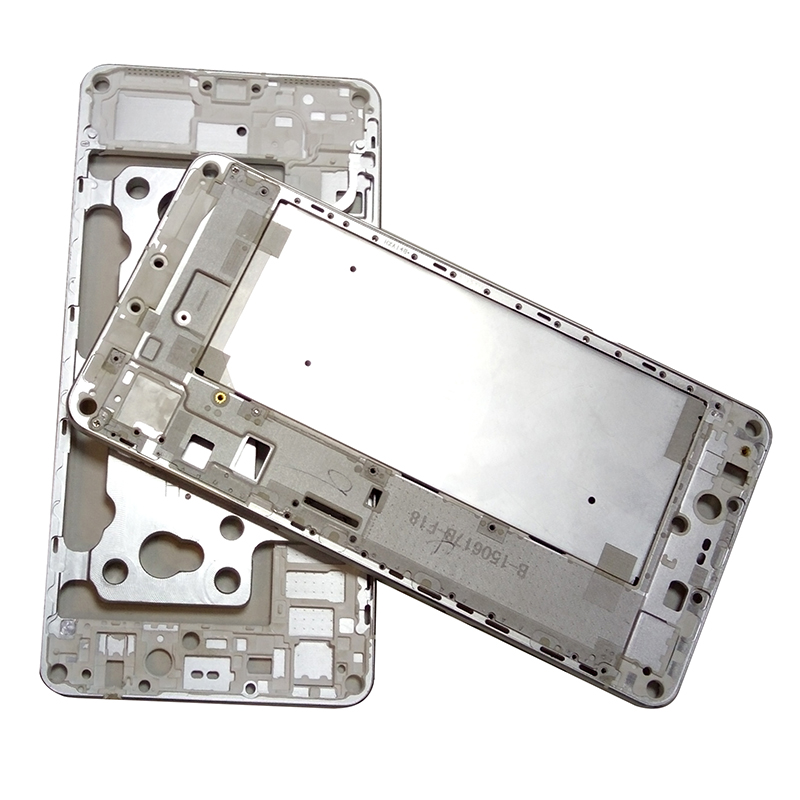

Casting Mobile Phone Accessories

Aluminum Die Cast