Advantages of 5-Axis CNC Milling

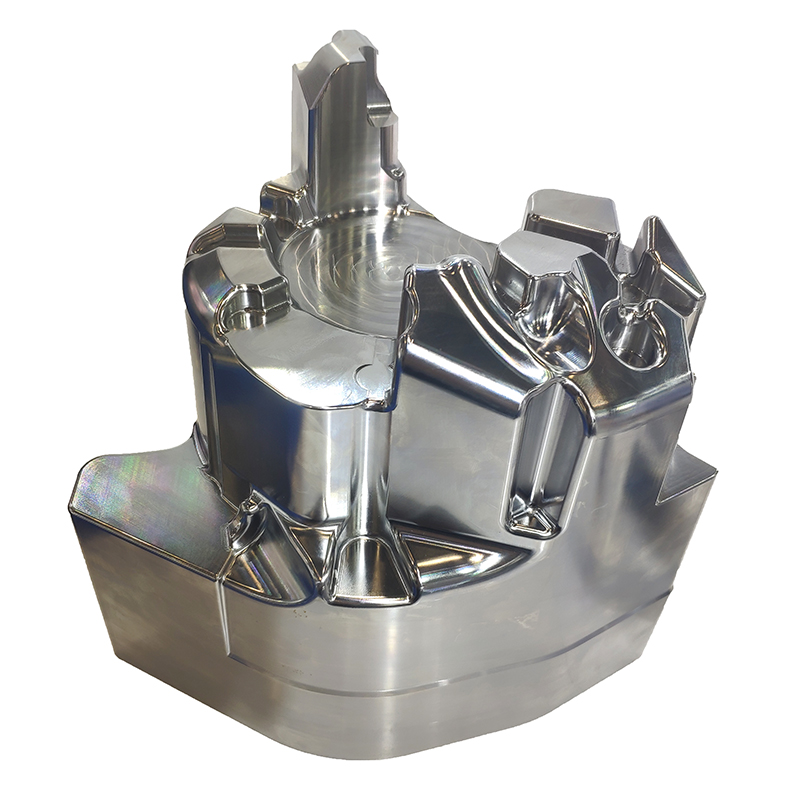

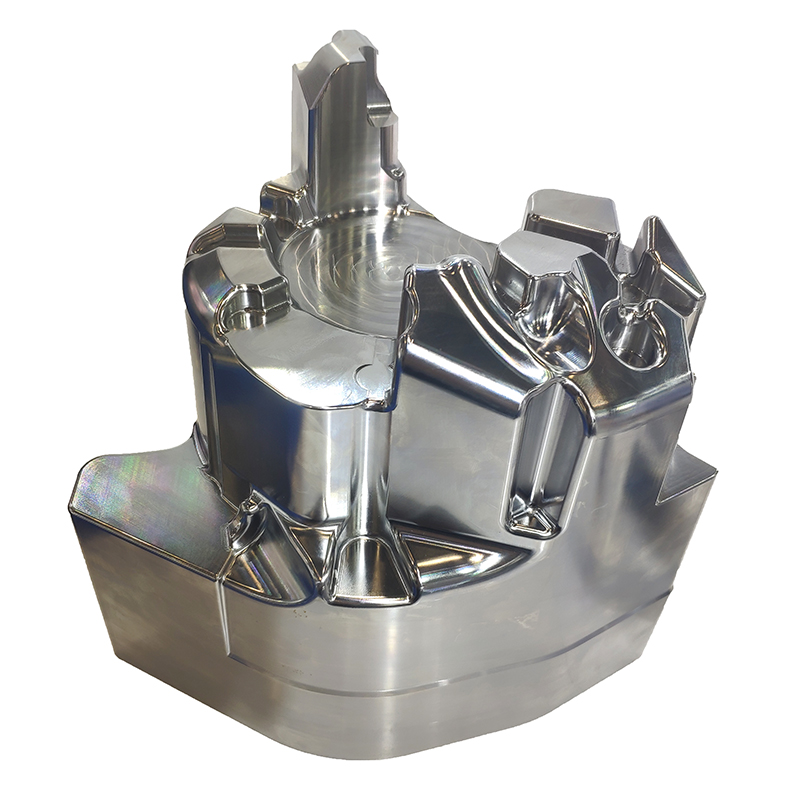

High-quality surface finish: It is feasible to produce high-quality machined finish parts with the use of shorter cutters with a higher cutting speed, which can reduce the vibration that frequently occurs when machining deep cavities with a 3-axis process. It makes a smooth surface finish after machining.

Positioning accuracy: 5-axis simultaneous milling and machining has become crucial if your finished products must adhere to strict quality and performance specifications.5-axis CNC machining also eliminates the need to move the work piece among multiple workstations, thereby reducing the risk of error.

Short lead times: The enhanced capabilities of the 5-axis machine results in decreased production times, which translate into shorter lead times for production compared to the 3-axis machine.