Nuacht

-

An Idirghníomh Criticiúil Idir Lamháltais Gheoiméadracha agus Toiseacha i gCodanna CNC

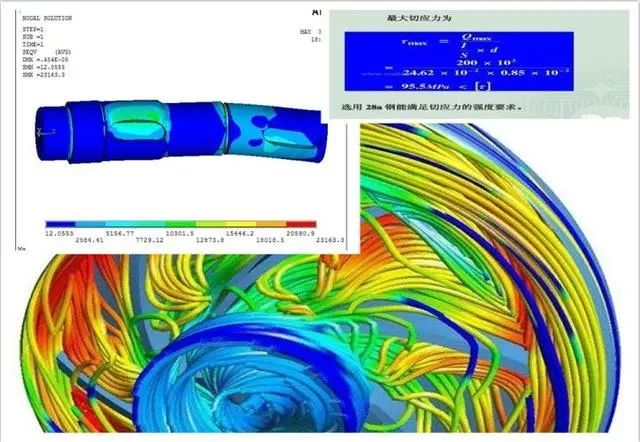

Bíonn tionchar ag earráid tríthoiseach agus earráid chruth araon ar chruinneas paraiméadair gheoiméadracha páirteanna meicniúla.Is minic a shonraíonn dearaí páirteanna meicniúla lamháltais tríthoiseacha agus lamháltais gheoiméadracha ag an am céanna.Cé go bhfuil difríochtaí agus naisc idir an dá, an cruinneas ...Leigh Nios mo -

Cruinn go Miocrón: Mar a Cruthaíonn Draoi Meaisínithe Ár nDomhan

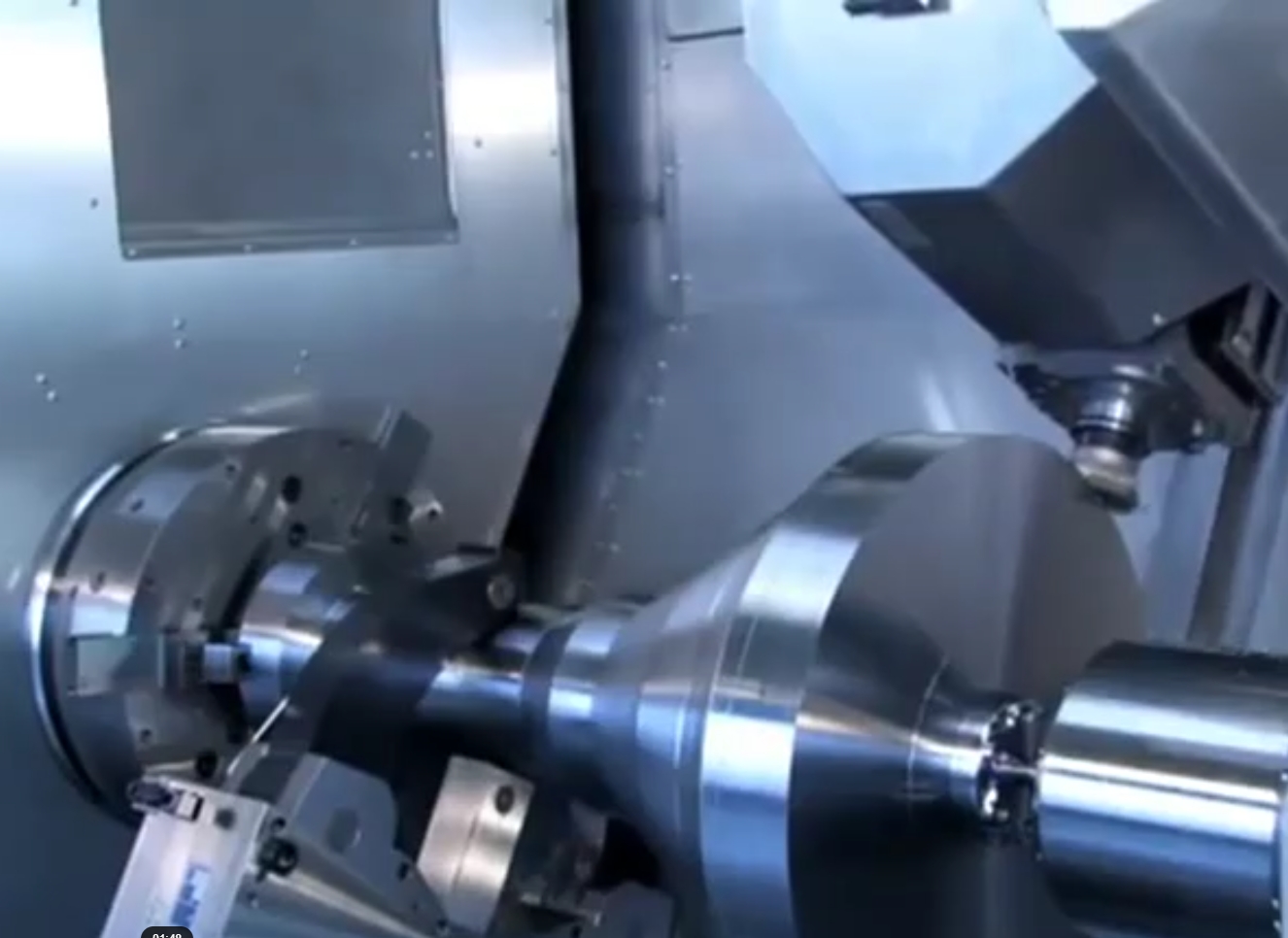

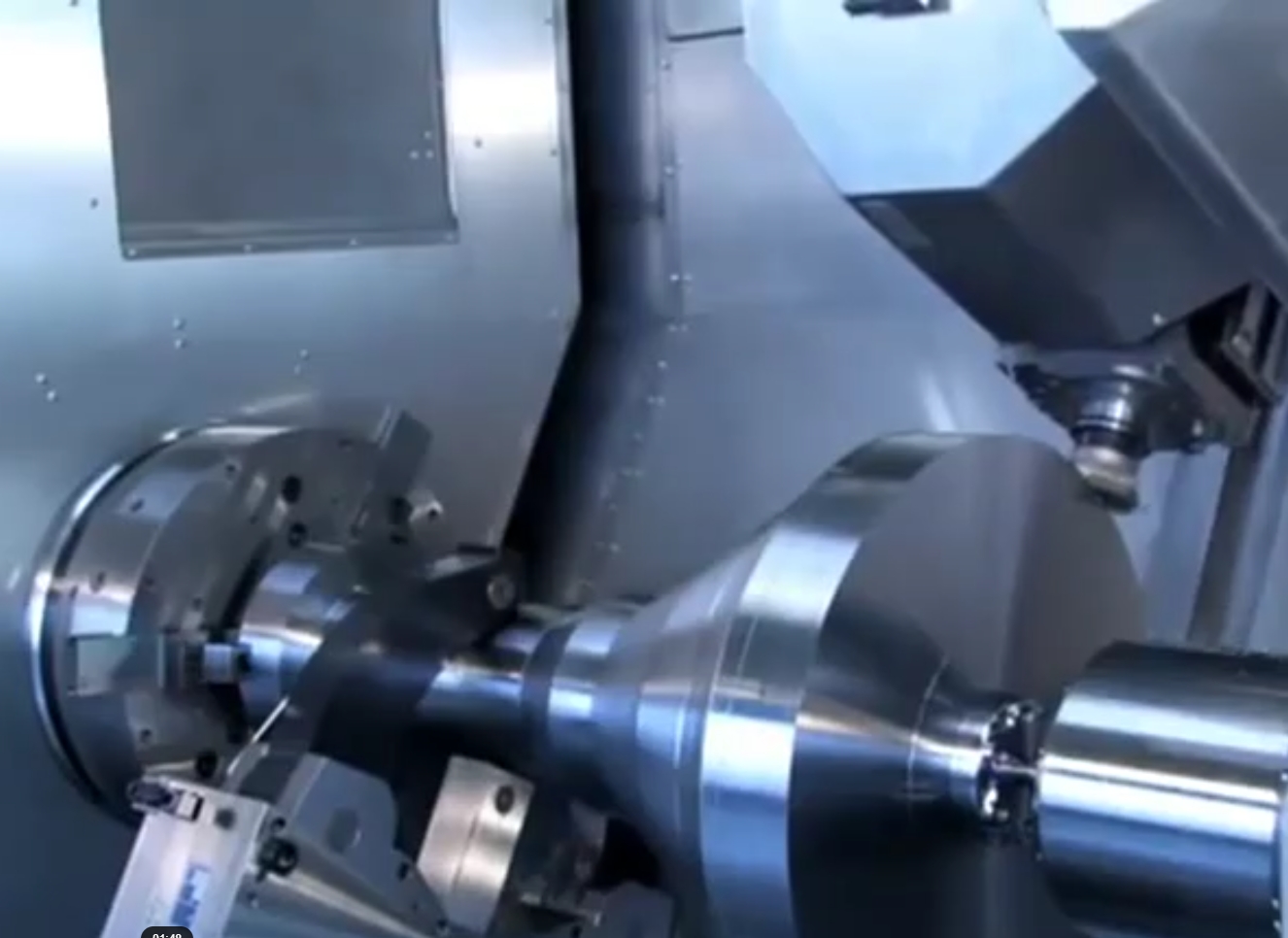

Is é cruinneas próiseála an méid a mheaitseálann méid, cruth agus suíomh iarbhír na dtrí pharaiméadar geoiméadrach de chuid próiseáilte na paraiméadair gheoiméadracha idéalach a éilíonn an líníocht.Tagraíonn na paraiméadair gheoiméadracha foirfe do mheánmhéid na coda, an geoiméadracht dromchla cosúil le ciorclach...Leigh Nios mo -

Agallamh Eisiach: An Tábhacht a bhaineann le hEolas Próisis Meaisínithe a Thuiscint

1. Cad iad na trí mhodhanna clampála workpieces?Tá trí mhodhanna ann chun píosaí oibre a chlampáil lena n-áirítear: 1) Clampáil sa daingneán 2) An clamp ceart a aimsiú go díreach 3) An líne a mharcáil agus an clamp ceart a aimsiú.2. Cad a chuimsíonn an córas próiseála?An phróiseáil...Leigh Nios mo -

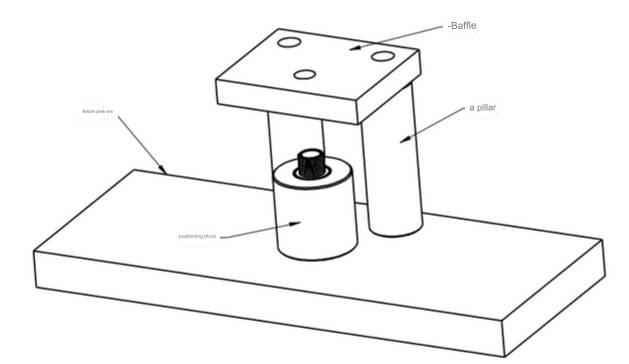

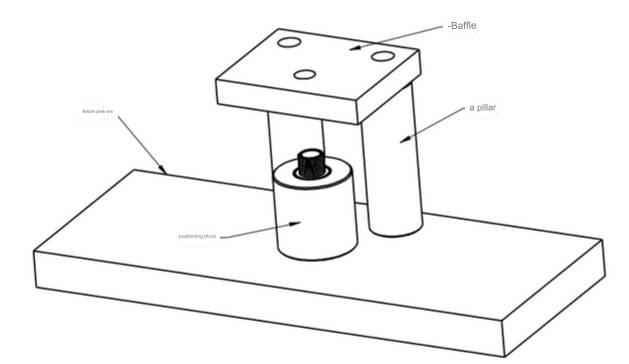

Faigh amach na Gnéithe Riachtanacha de 9 Daingneáin Oibre Éagsúla

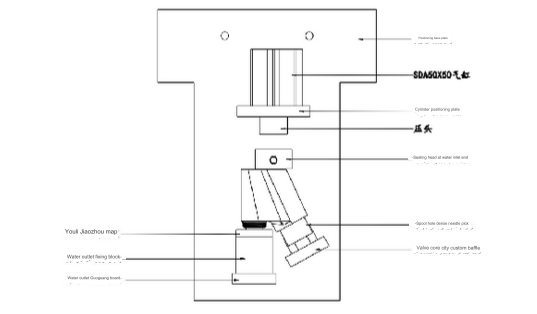

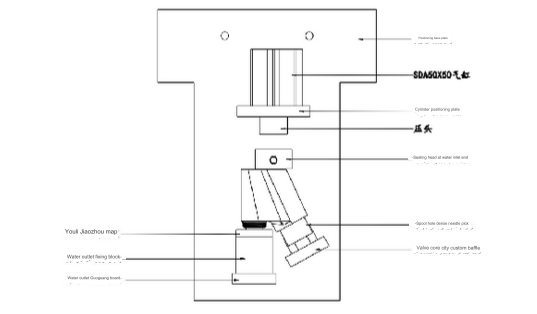

Is próiseas é dearadh daingneáin uirlisí atá oiriúnaithe do riachtanais shonracha próiseas déantúsaíochta ar leith.Déantar é seo tar éis próiseas meaisínithe na gcodanna a thabhairt chun críche.Agus an próiseas déantúsaíochta á fhorbairt, tá sé tábhachtach machnamh a dhéanamh ar fhéidearthacht feidhmithe...Leigh Nios mo -

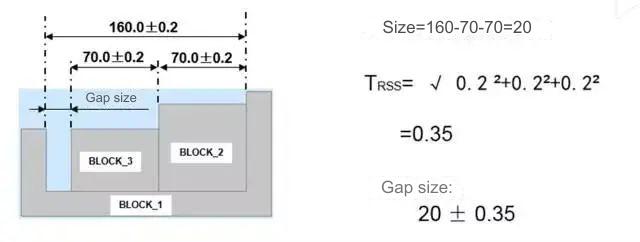

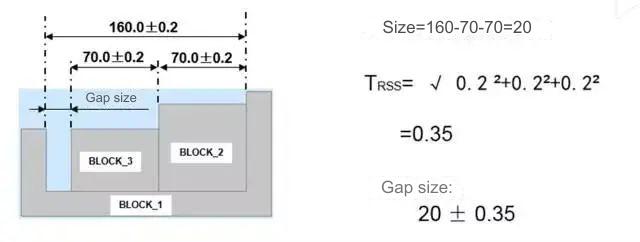

Mionsonraí rialaithe méide i ndearadh meicniúil a thuiscint |Teaglaim de phictiúir agus téacs

I ndearadh meicniúil, is léiriú ar chumas an dearthóra é toisí táirge a rialú.Mura bhfuil na scileanna deartha riachtanacha agat, féadfaidh sé a bheith deacair rialú méide a bhaint amach.Mar sin, ba mhaith liom roinnt próisis agus modhanna dearaidh bunúsacha a roinnt leat a d'fhéadfadh cabhrú leat a phriontáil ...Leigh Nios mo -

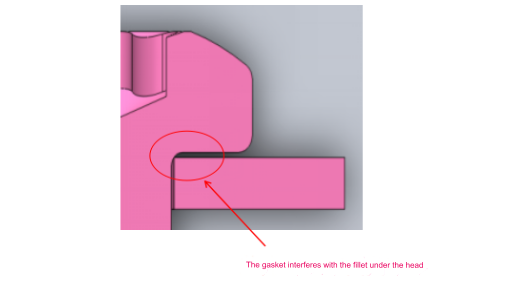

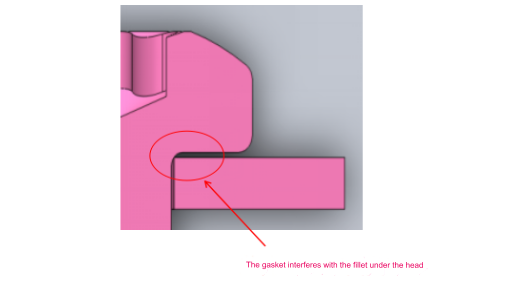

Agus tú ag géarú boltaí agus cnónna, ar chóir duit leicneáin árasán nó leicneáin earraigh a úsáid?

Ba mhaith le go leor daoine leicneáin árasán nó leicneáin earraigh a shábháil chun costais a shábháil.Go deimhin, tá ról fíor-riachtanach ag leicneáin árasán agus leicneáin earraigh in úsáid boltaí.Sa lá atá inniu cuirfimid pillíní árasán agus pillíní earraigh in aithne duit.Ceap árasán ar chlé, eochaircheap earrach ar dheis Is éard atá i níocháin árasán...Leigh Nios mo -

An tábhacht a bhaineann le leaba scríobtha láimhe le haghaidh uirlisí meaisín cruinneas

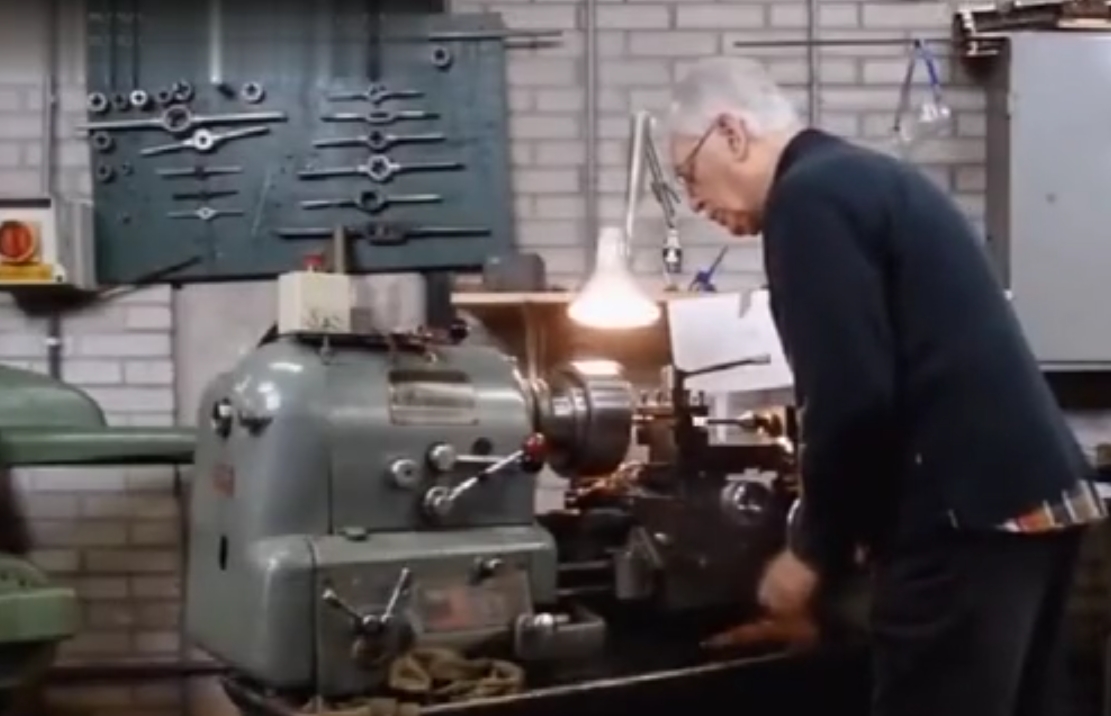

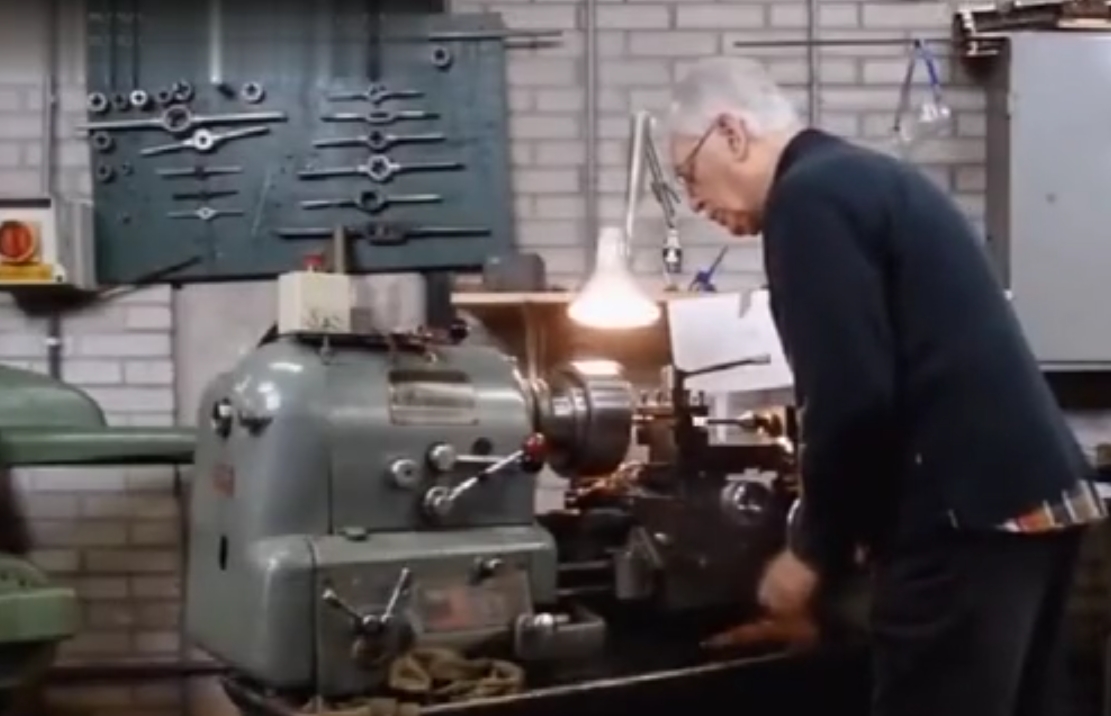

Cén fáth a gcaithfear uirlisí meaisín beachtais a scrapeadh de láimh?Is teicníocht an-dhúshlánach í an scríobadh a sháraíonn snoíodóireacht adhmaid ó thaobh castachta de.Feidhmíonn sé mar bhunús bunúsach le haghaidh feidhmeanna uirlisí cruinneas trí chríochnú dromchla cruinn a chinntiú.Cuireann scrapáil deireadh lenár spleáchas ar mheaisíní eile...Leigh Nios mo -

Coinnigh i gcuimhne na pointí dearaidh de daingneáin uirlisí speisialta |Cinntigh cobhsaíocht agus cruinneas próiseála uasta

De ghnáth tarlaíonn forbairt daingneáin uirlisí de réir riachtanais ar leith próiseas áirithe, a luaithe a bheidh próiseas meaisínithe na gcodanna bunaithe.Tá sé tábhachtach breithniú iomlán a dhéanamh ar an bhféidearthacht na daingneáin a chur i bhfeidhm agus an próiseas á fhoirmiú.Nuair a chruthaítear...Leigh Nios mo -

Máistreacht an Deil: Nochtadh Ocht dTeicnící Riachtanacha

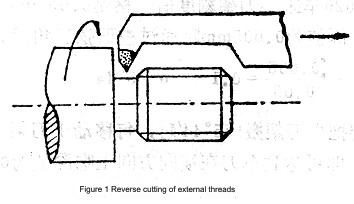

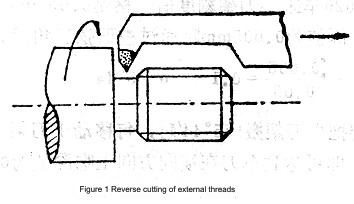

1. Faigh méideanna beaga bídeacha bia go cliste agus bain úsáid as feidhmeanna triantánúla go cliste Faigh méideanna beaga bia le hintleacht agus cuir feidhmeanna triantánúla i bhfeidhm go héifeachtach. Le linn an phróisis casadh, is minic a phróiseáiltear píosaí oibre le ciorcail laistigh agus lasmuigh a éilíonn cruinneas ard....Leigh Nios mo -

Modhanna Ceannródaíocha agus Feidhmchláir Sciliúla chun Dífhoirmiú Páirt Alúmanam a Chosc

Cuireann go leor fachtóirí le saobhadh comhpháirteanna alúmanaim le linn an phróisis déantúsaíochta, lena n-áirítear airíonna ábhar, céimseata páirteanna, agus paraiméadair táirgthe.Cuimsíonn na fachtóirí príomhúla strus inmheánach laistigh den amhábhar, saobhadh mar thoradh ar fhórsaí meaisínithe agus ...Leigh Nios mo -

Riachtanais Chriticiúla le haghaidh Blueprints Innealra

Clúdaíonn na Riachtanais Theicniúla maidir le líníochtaí meicniúla arna dtiomsú ag foireann Anebon an t-eolaire bunriachtanais seo a leanas: 1. Ceanglais theicniúla ghinearálta 2. Riachtanas cóireála teasa 3. Ceanglas lamháltais 4. Cuid Uillinn 5. Ceanglas cóimeála 6. Riachtanas réitigh 7. Riachtanas sciath .. .Leigh Nios mo -

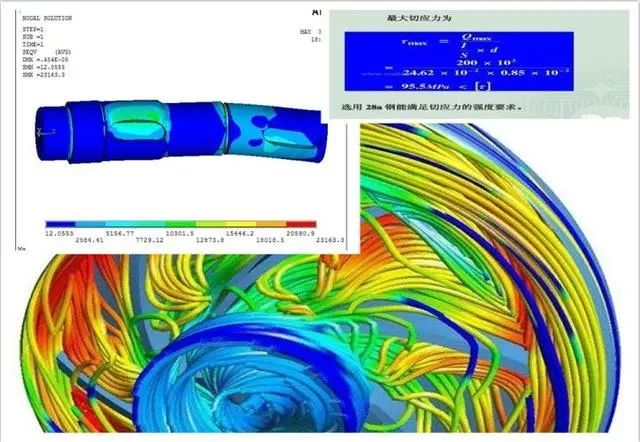

Treoir Chuimsitheach maidir le Cruach Dhosmálta

Is rogha coitianta é cruach dhosmálta chun ionstraimí a dhéanamh.Is féidir le foghlaim faoi chruach dhosmálta cabhrú le húsáideoirí uirlisí a bheith níos cumasaí maidir le huirlisí a roghnú agus a úsáid go héifeachtach.Tá cruach dhosmálta, a ghiorrú go minic mar SS, in ann nochtadh d'aer, gal, uisce agus eile a sheasamh ...Leigh Nios mo