Kulondola kwa magawo amakanika a geometric kumatengera zolakwika zonse ndi mawonekedwe.Mapangidwe a magawo amakina nthawi zambiri amawonetsa kulolerana kwazithunzi ndi kulekerera kwa geometric nthawi imodzi.Ngakhale pali kusiyana ndi kugwirizana pakati pa ziwirizi, zolondola zofunikira za magawo a geometric zimatsimikizira mgwirizano pakati pa kulolerana kwa geometric ndi kulolerana kwapakati, malingana ndi momwe mawotchi amagwiritsira ntchito.

1. Mfundo zingapo zololera zokhudzana ndi ubale pakati pa kulolerana kwazithunzi ndi kulolerana kwa geometric

Mfundo zololera ndi malamulo omwe amatsimikizira ngati kulolerana kwazithunzi ndi kulekerera kwa geometric kungagwiritsidwe ntchito mosiyana kapena ayi.Ngati kulolerana uku sikungasinthidwe wina ndi mzake, kumatengedwa ngati mfundo zodziimira.Kumbali ina, ngati kutembenuka kumaloledwa, ndi mfundo yogwirizana.Mfundozi zimagawidwanso m'magulu onse ofunikira, zofunikira zonse za bungwe, zofunikira zochepa za bungwe, ndi zomwe zingathe kusinthidwa.

2. Mawu oyambira

1) Kukula kwenikweni komweko D al, d al

Mtunda woyezedwa pakati pa mfundo ziwiri zofananira pagawo lililonse lodziwika bwino.

2) Kukula kwa zochita zakunja D fe, d fe

Tanthauzoli limatanthawuza m'mimba mwake kapena m'lifupi mwa malo abwino kwambiri omwe amalumikizidwa kunja ndi malo enieni amkati kapena malo ang'onoang'ono abwino kwambiri omwe amalumikizidwa kunja ndi mawonekedwe enieni akunja pautali woperekedwa wa mawonekedwe omwe akuyesedwa.Pazinthu zomwe zimagwirizanitsidwa, mbali yozungulira kapena yapakati pa malo abwino iyenera kusunga ubale wa geometric woperekedwa ndi kujambula ndi datum.

3) Mu vivo zochita kukula D fi, d fi

M'mimba mwake kapena m'lifupi mwa malo ang'onoang'ono abwino kwambiri pokhudzana ndi thupi lenileni lamkati kapena malo abwino kwambiri okhudzana ndi thupi ndi mawonekedwe enieni akunja pautali woperekedwa wa mawonekedwe omwe akuyezedwa.

4) Zolemba malire thupi ogwira kukula MMVS

Kukula kwakukulu kwakuthupi kumatanthawuza kukula kwa zotsatira zakunja m'boma komwe kumakhala kothandiza kwambiri mwakuthupi.Zikafika pamtunda wamkati, kukula kwakukulu kolimba kolimba kumawerengedwa pochotsa mtengo wololera wa geometric (wosonyezedwa ndi chizindikiro) kuchokera pakukula kolimba.Kumbali ina, kumtunda wakunja, kukula kwake kolimba kokwanira kumawerengedwa powonjezera mtengo wololera wa geometric (womwe umasonyezedwanso ndi chizindikiro) mpaka kukula kolimba kwambiri.

MMVS= MMS± T-mawonekedwe

M'njirayi, mawonekedwe akunja amaimiridwa ndi chizindikiro "+", ndipo mkati mwake amaimiridwa ndi chizindikiro "-".

5) Kukula kochepa kothandiza kwa thupi LMVS

Kuchepa kogwira mtima kwa bungwe kumatanthawuza kukula kwa thupi pamene likugwira ntchito pang'ono.Ponena za malo amkati, kukula kocheperako kwa thupi kumawerengedwa powonjezera mtengo wa kulekerera kwa geometric pa kukula kwa thupi (monga momwe zikuwonetsera ndi chizindikiro pa chithunzi).Kumbali inayi, ponena za kumtunda kwakunja, kukula kwa thupi kocheperako kumawerengedwa pochotsa mtengo wa kulekerera kwa geometric kuchokera ku kukula kwa thupi (kusonyezedwanso ndi chizindikiro pa chithunzi).

LMVS= LMS ±t-mawonekedwe

M'mapangidwewo, chamkati chimatenga chizindikiro "+", ndipo chakunja chimatenga chizindikiro "-".

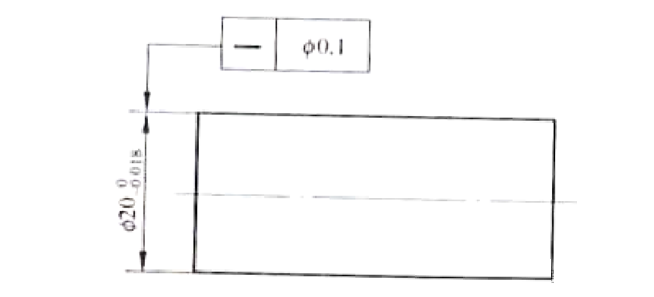

3. Mfundo ya ufulu wodziimira

Mfundo yodziyimira pawokha ndi mfundo yololera yomwe imagwiritsidwa ntchito popanga uinjiniya.Izi zikutanthauza kuti kulolerana kwa geometric ndi kulolerana kwapang'onopang'ono komwe kumatchulidwa muzojambula ndizosiyana ndipo palibe mgwirizano wina ndi mzake.Kulekerera konseku kumayenera kukwaniritsa zofunikira zawo palokha.Ngati kulolerana kwa mawonekedwe ndi kulolerana kwazithunzi kumatsata mfundo yodziyimira pawokha, ziwerengero zawo ziyenera kulembedwa pachojambula padera popanda zolembera zina.

Kuti muwonetsetse kuti magawo omwe akuwonetsedwa pachithunzichi, ndikofunikira kulingalira za kulekerera kwa shaft m'mimba mwake Ф20 -0.018 komanso kulolerana mowongoka kwa axis Ф0.1 paokha.Izi zikutanthauza kuti gawo lililonse liyenera kukwaniritsa zofunikira pazokha, motero ziyenera kuyang'aniridwa padera.

Dera la shaft liyenera kugwera pakati pa Ф19.982 mpaka 20, ndi cholakwika chololedwa kuwongoka pakati pa Ф0 mpaka 0.1.Ngakhale kuchuluka kwake kwa kukula kwenikweni kwa shaft kumatha kupitilira mpaka Ф20.1, sikuyenera kuyendetsedwa.Mfundo yodziyimira pawokha imagwira ntchito, kutanthauza kuti m'mimba mwake simayang'aniridwa mozama.

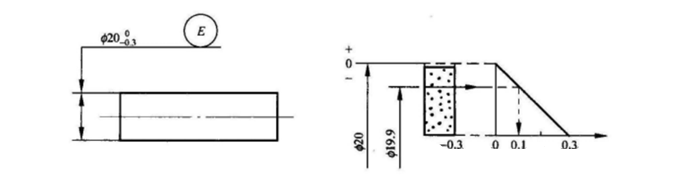

4. Mfundo yololera

Pamene chithunzi chophiphiritsa chikuwonekera pambuyo pa kupatuka kwa malire a dimensional kapena tolerance zone code ya chinthu chimodzi pajambula, zikutanthauza kuti chinthu chimodzi chimakhala ndi zofunikira zololera.Kuti mukwaniritse zofunikira zachitetezo, gawo lenileni liyenera kutsata malire akuthupi.Mwa kuyankhula kwina, kukula kwa mawonekedwe akunja sayenera kupitirira malire ake enieni, ndipo kukula kwake kwenikweni sikuyenera kukhala kochepa kuposa kukula kwake kochepa.

Chiwerengerochi chikuwonetsa kuti mtengo wa dfe uyenera kukhala wocheperako kapena wofanana ndi 20mm, pomwe mtengo wa dal uyenera kukhala wokulirapo kapena wofanana ndi 19.70mm.Poyang'anira, mawonekedwe a cylindrical adzaonedwa kuti ndi oyenerera ngati angadutse muyeso wathunthu wokhala ndi mainchesi a 20mm ndipo ngati kukula kwenikweni komweko komwe kuyeza pamfundo ziwiri ndikokulirapo kapena kofanana ndi 19.70mm.

The kulolerana chofunika ndi kulolerana chofunika kuti nthawi imodzi amazilamulira kukula kwenikweni ndi mawonekedwe zolakwika mkati dimensional kulolerana osiyanasiyana.

5. Zofunikira zazikulu zamabungwe ndi zofunika kuti zisinthe

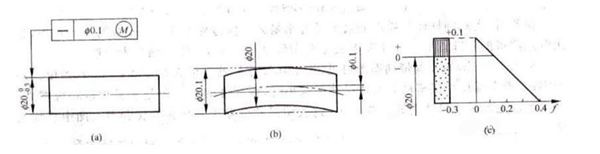

Pa chojambula, pamene chithunzi chophiphiritsa chikutsatira mtengo wololera mu bokosi la kulekerera kwa geometric kapena kalata yofotokozera, zikutanthauza kuti chinthu choyezera ndi chinthu cholozera kutengera zofunikira kwambiri zakuthupi.Tiyerekeze kuti chithunzicho chalembedwa pambuyo pa chithunzi cha chizindikiro pambuyo pa mtengo wa geometric tolerance wa chinthu choyezedwa.Zikatero, zikutanthawuza kuti kufunikira kosinthika kumagwiritsidwa ntchito pazofunikira zolimba kwambiri.

1) Kufunika kwakukulu kwazinthu kumagwiritsidwa ntchito pazinthu zoyezedwa

Poyezera chinthu, ngati chiwongola dzanja chikugwiritsidwa ntchito, kulekerera kwa geometric kuperekedwa kokha pamene mawonekedwewo ali mumpangidwe wake wokhazikika.Komabe, ngati mkombero weniweni wa mawonekedwewo ukupatuka pazigawo zake zolimba kwambiri, kutanthauza kuti kukula kwake komweko kuli kosiyana ndi kukula kwake kolimba, mawonekedwe ndi mawonekedwe olakwika amatha kupitilira mtengo wololera womwe umaperekedwa pazigawo zolimba kwambiri, ndi Pazipita owonjezera kuchuluka adzakhala wofanana pazipita olimba boma.Ndikofunikira kudziwa kuti kulolerana kwapang'onopang'ono kwa chinthu choyezedwa kuyenera kukhala mkati mwake komanso kukula kwake kochepa, ndipo kukula kwake kwenikweni kuyenera kusapitilira kukula kwake kwakukulu.

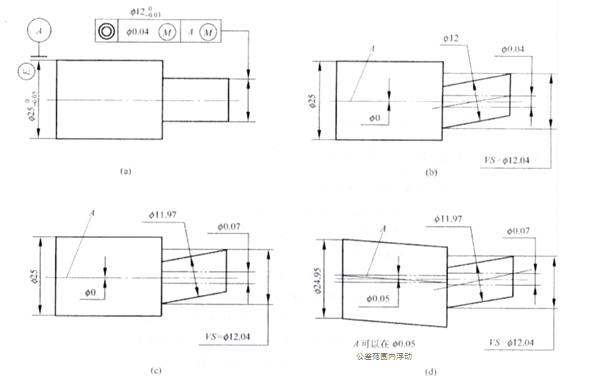

Chithunzichi chikuwonetsa kulolerana mowongoka kwa axis, komwe kumatsatira zofunikira kwambiri zakuthupi.Pamene shaft ili pamtunda wake wolimba kwambiri, kulolerana mowongoka kwa axis yake ndi Ф0.1mm (Chithunzi b).Komabe, ngati kukula kwenikweni kwa shaft kumachoka pamlingo wake wolimba kwambiri, cholakwika chovomerezeka chololeka f cha axis yake chikhoza kuonjezedwa moyenerera.Chithunzi cha malo olekerera choperekedwa mu Chithunzi C chikuwonetsa ubale wofananira.

Kutalika kwa shaft kuyenera kukhala pakati pa Ф19.7mm mpaka Ф20mm, ndi malire a Ф20.1mm.Kuti muwone momwe shaft ilili, yesani kaye chiwongolero chake molingana ndi geji yomwe ikugwirizana ndi kukula kwake kwamphamvu kwa Ф20.1mm.Kenaka, gwiritsani ntchito njira ziwirizi kuti muyese kukula kwake kwenikweni kwa shaft ndikuwonetsetsa kuti ikugwera mumiyeso yovomerezeka ya thupi.Ngati miyeso ikukwaniritsa izi, shaft imatha kuonedwa ngati yoyenera.

Chithunzi chosinthika cha malo olekerera chikuwonetsa kuti ngati kukula kwenikweni kumachepa kuchokera pamlingo wokhazikika wokhazikika ndi Ф20mm, cholakwika chololeka chololeka f mtengo chimaloledwa kuwonjezeka molingana.Komabe, kuwonjezeka kwakukulu sikuyenera kupitirira kulolerana kwa dimensional.Izi zimathandiza kusintha kwa dimensional kulolerana mu mawonekedwe ndi udindo kulolerana.

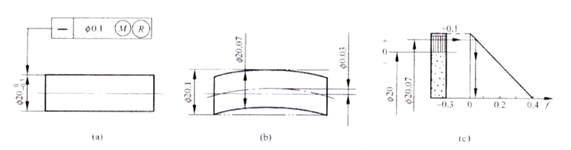

2) Zofunikira zosinthika zimagwiritsidwa ntchito pazomwe zimafunikira kwambiri

Zofunikira pakubwezeretsanso zikagwiritsidwa ntchito pakufunika kolimba kwambiri, mizere yeniyeni ya chinthu chomwe ikuyezedwa iyenera kugwirizana ndi malire ake olimba kwambiri.Ngati kukula kwenikweni kumapatuka pakukula kolimba kwambiri, cholakwika cha geometric chimaloledwa kupitilira mtengo womwe wapatsidwa.Kuonjezera apo, ngati cholakwika cha geometric ndi chocheperapo kusiyana ndi kusiyana kwa geometric kusiyana mu chikhalidwe cholimba kwambiri, kukula kwenikweni kungathenso kupitirira miyeso yolimba kwambiri, koma kupitirira kovomerezeka kovomerezeka ndi kufanana kwamtundu wakale komanso kulolerana kwamtundu wopatsidwa. kwa omaliza.

Chithunzi A ndi fanizo la kugwiritsa ntchito zofunikira zosinthika pazofunikira zolimba kwambiri.Mzere uyenera kukhutiritsa d fe ≤ Ф20.1mm, Ф19.7 ≤ d al ≤ Ф20.1mm.

Ndondomeko yomwe ili pansipa ikufotokoza kuti ngati kukula kwenikweni kwa shaft kumachokera ku malo olimba kwambiri kupita ku malo olimba kwambiri, cholakwika chowongoka cha axis chikhoza kufika pamtengo wapatali, womwe ndi wofanana ndi 0.1mm kulolerana kwa 0.1mm yoperekedwa muzojambula. kukula kulolerana kwa kutsinde ndi 0.3mm.Izi zimabweretsa chiwerengero cha Ф0.4mm (monga momwe tawonetsera pa Chithunzi c).Ngati mtengo wa zolakwika zowongoka wa axis ndi wocheperapo kusiyana ndi kulekerera kwa 0.1mm woperekedwa pachithunzicho, ndi Ф0.03mm, ndipo kukula kwake kwenikweni kungakhale kokulirapo kuposa kukula kwake kwa thupi, kufika ku Ф20.07mm (monga momwe tawonetsera pa Chithunzi) b).Kulakwitsa kowongoka kukakhala ziro, kukula kwake kwenikweni kumatha kufika pamtengo wokwera kwambiri, womwe umafanana ndi kukula kwake kwamphamvu kwamphamvu kwa Ф20.1mm, motero kukwaniritsa kufunikira kosintha kulolerana kwa geometric kukhala kulolerana kwapang'onopang'ono.Chithunzi c ndi chithunzi chosinthika chomwe chikuwonetsa kulolerana kwa ubale womwe wafotokozedwa pamwambapa.

Pakuwunika, makulidwe enieni a shaft amafaniziridwa ndi mawonekedwe athunthu, omwe amapangidwa kutengera kukula kwamalire kogwira mtima kwa 20.1mm.Kuonjezera apo, ngati kukula kwenikweni kwa shaft, monga momwe amayezera pogwiritsa ntchito njira ya mfundo ziwiri, ndi yaikulu kuposa kukula kwa thupi kwa 19.7mm, ndiye kuti gawolo limaonedwa kuti ndiloyenera.

3) Zofunikira zazikulu zamabizinesi zimagwiranso ntchito pazinthu zamadatum

Mukamagwiritsa ntchito zofunikira zolimba kwambiri pamawonekedwe a datum, datum iyenera kugwirizana ndi malire.Izi zikutanthauza kuti kukula kwa zochitika zakunja kwa gawo la datum kukasiyana ndi kukula kwa malire ake, chinthu cha datum chimaloledwa kuyenda mkati mwamitundu ina.Mulingo woyandama ndi wofanana ndi kusiyana pakati pa kukula kwa zochitika zakunja kwa chinthu cha datum ndi kukula kwamalire kofananira.Pamene chinthu cha datum chikupatuka kuchokera ku malo ocheperako, kuchuluka kwake koyandama kumawonjezeka mpaka kukafika pachimake.

Chithunzi A chikuwonetsa kulolerana kwa coaxiality kwa axis yakunja kwa bwalo lakunja.Zinthu zoyezedwa ndi ma datamu zimatengera zofunikira kwambiri panthawi imodzi.

Pamene chinthucho chili cholimba kwambiri, kulekerera kwa coaxiality kwa axis yake ku datum A ndi Ф0.04mm, monga momwe tawonetsera mu Chithunzi B. Mzere woyezera uyenera kukhutiritsa d fe≤Ф12.04mm, Ф11.97≤d al≤Ф12mm .

Pamene chinthu chaching'ono chikuyesedwa, ndizovomerezeka kuti cholakwika cha coaxiality cha axis yake chifike pamtengo wapatali.Mtengo uwu ndi wofanana ndi kuchuluka kwa kulolerana kuwiri: kulolerana kwa coaxiality kwa 0.04mm komwe kumatchulidwa pachithunzichi ndi kulolerana kwapang'onopang'ono kwa axis, komwe ndi Ф0.07mm (monga momwe tawonetsera pa Chithunzi c).

Pamene nsonga ya datum ili pamtunda waukulu, ndi kukula kwakunja kwa Ф25mm, kulolerana kwapang'onopang'ono pajambula kungakhale Ф0.04mm.Ngati kukula kwakunja kwa datum kumachepetsa kukula kwake kwa Ф24.95mm, olamulira a datum amatha kuyandama mkati mwa kulolerana kwa Ф0.05mm.Pamene olamulira ali mu mkhalidwe woyandama kwambiri, kulekerera kwa coaxiality kumawonjezeka kufika pa datum dimensional tolerance value ya Ф0.05mm.Chotsatira chake, pamene zinthu zoyezera ndi datum zimakhala zolimba nthawi imodzi, zolakwika zazikulu za coaxiality zimatha kufika ku Ф0.12mm (Chithunzi d), chomwe ndi chiwerengero cha 0.04mm cha kulekerera kwa coaxiality, 0.03mm kwa kulolerana kwa datum dimensional ndi 0.05mm pakulolera koyandama kwa datum axis.

6. Zofunikira zochepa zamabizinesi ndi zofunika kuti zisinthe

Ngati muwona chithunzi cha chizindikiro cholembedwa pambuyo pa mtengo wololera kapena chilembo cha datum mu bokosi la kulekerera kwa geometric pajambula, zimasonyeza kuti chinthu choyezera kapena datum chiyenera kukwaniritsa zofunikira zochepa za thupi, motero.Kumbali ina, ngati pali chizindikiro pambuyo pa mtengo wa geometric tolerance wa chinthu choyezedwa, zikutanthauza kuti chofunikira chosinthika chimagwiritsidwa ntchito pazomwe zimafunikira.

1) Zofunikira zochepa zamabizinesi zimagwira ntchito pazofunikira pakuyesedwa

Mukamagwiritsa ntchito zinthu zochepera zomwe zimafunikira pa chinthu choyezedwa, autilaini yeniyeni ya chinthucho sayenera kupitilira malire ake pautali uliwonse.Kuphatikiza apo, kukula kwenikweni kwa chinthucho kuyenera kusapitilire kapena kuchepera kwa chinthucho.

Ngati chocheperako cholimba chikagwiritsidwa ntchito poyezedwa, mtengo wa geometric tolerance umaperekedwa pomwe mawonekedwewo ali olimba.Komabe, ngati mkombero weniweni wa mawonekedwewo upatuka pakukula kwake kolimba kocheperako, mawonekedwe ndi malo olakwika atha kupitilira mtengo wololera womwe waperekedwa mugawo lolimba locheperako.Zikatero, yogwira kukula kwa mbali anayeza sayenera upambana osachepera olimba, ogwira malire kukula kwake.

2) Zofunikira zosinthika zimagwiritsidwa ntchito pazofunikira zochepa za bungwe

Mukamagwiritsa ntchito zomwe zimafunikira kuti zisinthidwe pazomwe zimafunikira, gawo lenileni la gawo lomwe layezedwa siliyenera kupitilira malire ake olimba, ogwira ntchito pautali uliwonse.Kuonjezera apo, kukula kwake kwenikweni sikuyenera kupitirira kukula kolimba.Pansi pazimenezi, osati kokha kuti cholakwika cha geometric chimaloledwa kupitirira mtengo wololera wa geometric womwe umaperekedwa mu chikhalidwe chochepa cha thupi pamene kukula kwenikweni kwa chinthu choyezera kumapatuka ku kukula kochepa kwa thupi, komanso kumaloledwa kupitirira kukula kwa thupi pamene kukula kwenikweni ndi kosiyana, malinga ngati cholakwika cha geometric ndi chaching'ono kuposa mtengo womwe wapatsidwa.

Thecnc makinazofunikira zolimba zocheperako komanso kusinthika kwake ziyenera kugwiritsidwa ntchito pokhapokha kulolerana kwa geometric kumagwiritsidwa ntchito kuwongolera gawo logwirizana.Komabe, kugwiritsa ntchito zofunikira izi kapena ayi kumadalira zofunikira zenizeni za chinthucho.

Pamene mtengo wololera wa geometric ndi ziro, zofunikira kwambiri (zochepa) zolimba ndi zofunikira zosinthika zimatchedwa zero tolerances.Pakadali pano, malire ofananira adzasintha pomwe mafotokozedwe ena sasintha.

7. Kudziwitsa za kulekerera kwa geometric

1) Kutsimikiza kwa mawonekedwe a jekeseni ndi kulekerera kwa malo

Ambiri, Ndi bwino kuti kulolerana makhalidwe ayenera kutsatira ubale wapadera, ndi mawonekedwe kulolerana kukhala ang'onoang'ono kuposa malo kulolerana ndi dimensional kulolerana.Komabe, ndikofunikira kuzindikira kuti muzochitika zachilendo, kulolerana mowongoka kwa axis ya shaft yocheperako kungakhale kokulirapo kuposa kulolerana kwazithunzi.Kulekerera kwa malo kuyenera kukhala kofanana ndi kulolerana kwapang'onopang'ono ndipo nthawi zambiri kumafanana ndi kulolerana kwa ma symmetry.

Ndikofunika kuonetsetsa kuti kulolerana kwa malo nthawi zonse kumakhala kwakukulu kuposa kulolerana kwamayendedwe.Kulekerera kwa malo kungaphatikizepo zofunikira za kulolerana, koma zosiyana sizowona.

Kuphatikiza apo, kulolerana kokwanira kuyenera kukhala kwakukulu kuposa kulolerana kwamunthu payekha.Mwachitsanzo, kulolerana kwa cylindricity kwa pamwamba pa silinda kumatha kukhala kwakukulu kuposa kapena kofanana ndi kulolerana mowongoka kwa kuzungulira, mzere woyamba, ndi axis.Mofananamo, kulolerana kwa flatness kwa ndegeyo kuyenera kukhala kwakukulu kuposa kapena kofanana ndi kulolerana mowongoka kwa ndege.Potsirizira pake, kulolerana kwamtundu uliwonse kuyenera kukhala kwakukulu kuposa kuthamanga kozungulira kozungulira, kuzungulira, cylindricity, kuwongoka kwa mzere woyamba ndi axis, ndi kulekerera kofanana kofanana.

2) Kudziwitsa za kulekerera kwa geometric zosadziwika

Kuti zojambula zaumisiri zikhale zazifupi komanso zomveka bwino, ndizosankha kuwonetsa kulolerana kwazithunzi pazithunzi za kulondola kwa geometric zomwe ndizosavuta kutsimikizira pakukonza zida zamakina.Pazinthu zomwe zofunikira zololera mawonekedwe sizikunenedwa mwachindunji pajambula, mawonekedwe ndi malo olondola amafunikiranso.Chonde tchulani malamulo ogwiritsira ntchito GB / T 1184. Zojambula zojambula popanda kulekerera zikhalidwe ziyenera kuzindikiridwa muzolemba za block block kapena muzofunikira zamakono ndi zolemba zamakono.

Zida zosinthira zamagalimoto zapamwamba kwambiri,mphero,ndizitsulo zotembenuzidwa mbaliamapangidwa ku China, Anebon.Zogulitsa ku Anebon zakhala zikudziwika mochulukirachulukira kuchokera kwa makasitomala akunja ndikukhazikitsa maubale anthawi yayitali komanso ogwirizana nawo.Anebon ipereka chithandizo chabwino kwambiri kwa kasitomala aliyense ndikulandila abwenzi moona mtima kuti azigwira ntchito ndi Anebon ndikukhazikitsa zopindulitsa zonse pamodzi.

Nthawi yotumiza: Apr-16-2024