Ukunemba kwezinhlaka zejiyomethri zezingxenye zomshini kuthonywa kokubili iphutha le-dimensional kanye nephutha lomumo.Imiklamo yezingxenye zemishini ivame ukucacisa ukubekezelela kobukhulu kanye nokubekezelelana kwejometri kanyekanye.Nakuba kunomehluko nokuxhumana phakathi kwakho kokubili, izidingo zokunemba zamapharamitha wejiyomethri zinquma ubudlelwano phakathi kokubekezelelana kwejometri nokubekezelelana kobukhulu, kuye ngezimo zokusetshenziswa kwengxenye yomshini.

1. Izimiso ezimbalwa zokubekezelela mayelana nobudlelwano phakathi kokubekezelelana kwe-dimensional nokubekezelelana kwejometri

Izimiso zokubekezelela ziyimithethonqubo enquma ukuthi ukubekezelelana kwe-dimensional nokubekezelelana kwejometri kungasetshenziswa ngokushintshana noma cha.Uma lokhu kubekezelelana kungenakuguqulelwa komunye nomunye, kubhekwa njengezimiso ezizimele.Ngakolunye uhlangothi, uma ukuguqulwa kuvunyelwe, kuyisimiso esihlobene.Le migomo iphinde ihlukaniswe yaba yizidingo ezibandakanya bonke abantu, izidingo eziphezulu zebhizinisi, izimfuneko eziyisisekelo zebhizinisi, nezimfuneko ezingahlehliswa.

2. Amagama ayisisekelo

1) Usayizi wangempela wendawo D al, d al

Ibanga elikalwa phakathi kwamaphoyinti amabili ahambelanayo kunoma iyiphi ingxenye evamile yesici sangempela.

2) Usayizi wesenzo sangaphandle D fe, d fe

Le ncazelo ibhekisela kububanzi noma ububanzi bendawo enkulu kunazo zonke ekahle exhunywe ngaphandle endaweni yangempela yangaphakathi noma indawo encane efanelekile exhunywe ngaphandle endaweni yangempela yangaphandle ngobude obunikeziwe besici esilinganiswayo.Ezicini ezihlotshaniswayo, i-eksisi noma indiza emaphakathi yendawo ekahle kufanele igcine ubudlelwano bejiyomethri obunikezwa umdwebo nedatum.

3) Usayizi wesenzo se-vivo D fi, d fi

Ububanzi noma ububanzi bendawo encane efanelekile ekuthintaneni komzimba nendawo yangempela yangaphakathi noma indawo enkulu kunazo zonke ekahle ekuthintaneni komzimba nendawo engaphandle yangempela ngobude obunikeziwe besici esilinganiswayo.

4) Usayizi omkhulu osebenzayo we-MMVS

Ubukhulu bosayizi obusebenzayo obungokomzimba bubhekisela kusayizi womphumela wangaphandle esimweni lapho usebenza khona kakhulu ngokomzimba.Uma kuziwa endaweni engaphakathi, ubukhulu obuqinile obuqinile obusebenzayo bubalwa ngokukhipha inani lokubekezelela ijometri (elikhonjiswe uphawu) kusukela kusayizi oqinile ophelele.Ngakolunye uhlangothi, endaweni yangaphandle, ubukhulu obuqinile obuqinile obusebenzayo bubalwa ngokungeza inani lokubekezelela ijometri (futhi elikhonjiswe uphawu) kusayizi omkhulu oqinile.

MMVS= MMS± T-shape

Efomini, indawo engaphandle imelelwa uphawu oluthi “+”, kanti ingaphakathi limelwe uphawu elithi “-”.

5) Ubuncane bosayizi osebenzayo we-LMVS

Usayizi omncane osebenzayo webhizinisi ubhekisela kusayizi womzimba lapho usesimweni esisebenzayo okungenani.Uma kubhekiselwa endaweni engaphakathi, usayizi omncane osebenzayo osebenzayo ubalwa ngokwengeza inani lokubekezelela ijometri kusayizi womzimba omncane (njengoba kukhonjiswe uphawu esithombeni).Ngakolunye uhlangothi, uma kubhekiselwa endaweni engaphandle, ubuncane besayizi bomzimba obusebenzayo bubalwa ngokukhipha inani lokubekezelela ijometri kusuka kusayizi womzimba omncane (futhi okhonjiswe uphawu esithombeni).

LMVS= LMS ±t-shape

Efomini, indawo engaphakathi ithatha uphawu "+", futhi ingaphandle ithatha uphawu "-".

3. Isimiso sokuzimela

Umgomo wokuzimela uwumgomo wokubekezelelana osetshenziswa ekwakhiweni kobunjiniyela.Lokhu kusho ukuthi ukubekezelelana kwejiyomethri nokubekezelelana kobukhulu okucaciswe emdwebeni kuhlukene futhi akukho kuhlobana.Kokubili ukubekezelelana kufanele kuhlangabezane nezidingo zabo ezithile ngokuzimela.Uma ukubekezelelana komumo nokubekezelelana kwe-dimensional kulandela isimiso sokuzimela, amanani abo ezinombolo kufanele amakwe emdwebeni ngokuhlukana ngaphandle kwanoma yiziphi izimpawu ezengeziwe.

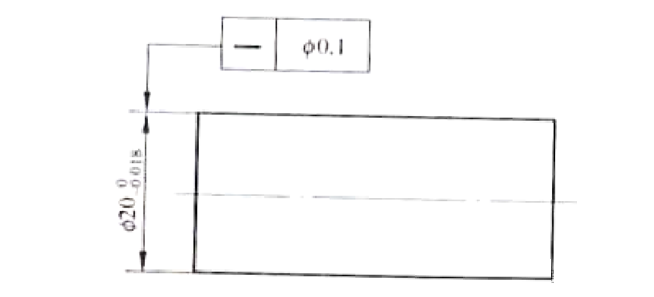

Ukuze kuqinisekiswe ikhwalithi yezingxenye ezivezwe emfanekisweni, kubalulekile ukucabangela ukubekezelelana kobukhulu bobubanzi be-shaft Ф20 -0.018 kanye nokubekezelelana kokuqondile kwe-axis Ф0.1 ngokuzimela.Lokhu kusho ukuthi ubukhulu obunye kufanele buhlangabezane nezidingo zokuklama bubodwa, ngakho-ke kufanele buhlolwe ngokwehlukana.

Ububanzi be-shaft kufanele buwele phakathi kobubanzi obungu-Ф19.982 ukuya ku-20, kube nephutha elivunyelwe lokuqondisa phakathi kobubanzi buka-Ф0 ukuya ku-0.1.Nakuba inani eliphezulu losayizi wangempela wobubanzi be-shaft lingase lidlulele ku-Ф20.1, alidingi ukulawulwa.Umgomo wokuzimela uyasebenza, okusho ukuthi ububanzi abuhlolisiswa ngokuphelele.

4. Isimiso sokubekezelelana

Uma isithombe sophawu sivela ngemva kokuchezuka komkhawulo we-dimensional noma ikhodi yendawo yokubekezelela ye-elementi eyodwa emdwebeni, kusho ukuthi isici esisodwa sinezidingo zokubekezelela.Ukuze kuhlangatshezwane nezimfuneko zokuqukatha, isici sangempela kufanele sithobelane nomkhawulo omkhulu ongokwenyama.Ngamanye amazwi, usayizi obambekayo wangaphandle wesici akumele udlule umkhawulo waso omkhulu obonakalayo, futhi usayizi wangempela wendawo akumele ube mncane kunosayizi oyisisekelo womzimba.

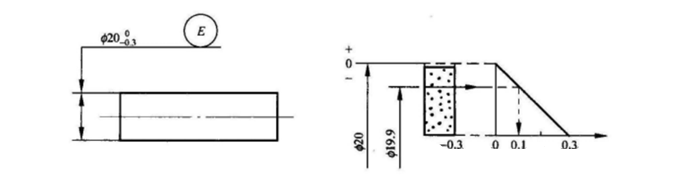

Isibalo sibonisa ukuthi inani le-dfe kufanele libe ngaphansi noma lilingane no-20mm, kuyilapho inani le-dal kufanele libe likhulu noma lilingane no-19.70mm.Ngesikhathi sokuhlolwa, indawo eyisilinda izothathwa njengefanelekile uma ingadlula kugeji yomumo ogcwele enobubanzi obungu-20mm futhi uma isamba sosayizi wangempela wasendaweni olinganiswa ngamaphoyinti amabili sikhulu noma silingana no-19.70mm.

Imfuneko yokubekezelelana iyisidingo sokubekezelelana esilawula ngesikhathi esisodwa ubukhulu bangempela namaphutha omumo ngaphakathi kwebanga lokubekezelela kobukhulu.

5. Ubuningi bezidingo zebhizinisi kanye nezidingo zabo zokuhlehla

Emdwebeni, uma isithombe sophawu silandela inani lokubekezelela ebhokisini lokubekezelela ijiyomethri noma uhlamvu lwereferensi, kusho ukuthi isici esilinganisiwe kanye nesici sereferensi sisebenzisa ubuningi bezidingo zomzimba.Ake sithi isithombe sifakwe ilebula ngemva kwesithombe sophawu ngemva kwevelu yokubekezelela kwejometri yento elinganisiwe.Kuleso simo, kusho ukuthi imfuneko ehlehliswayo isetshenziselwa isidingo esiphezulu esiqinile.

1) Isidingo esiphezulu sebhizinisi sisebenza kuzinto ezilinganisiwe

Lapho kukalwa isici, uma kusetshenziswa imfuneko enkulu yokuqina, inani lokubekezelela kwejiyomethri lesici lizonikezwa kuphela uma isici sikumumo waso oqinile omkhulu.Kodwa-ke, uma i-contour yangempela yesici ichezuka esimweni sayo esiphezulu esiqinile, okusho ukuthi usayizi wangempela wasendaweni uhlukile kusayizi oqinile omkhulu, inani lephutha lomumo nendawo lingeqa inani lokubekezelela elinikezwe esimweni esiqinile esiphezulu, futhi inani elikhulu eleqile lizolingana nesimo esiphezulu esiqinile.Kubalulekile ukuqaphela ukuthi ukubekezelela kobukhulu bento elinganisiwe kufanele ibe phakathi kobukhulu bayo kanye nosayizi omncane ongokomzimba, futhi usayizi wayo wangempela wasendaweni akufanele weqe ubukhulu bobukhulu bawo obungokomzimba.

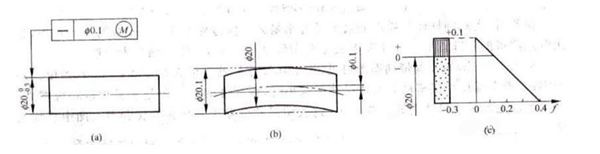

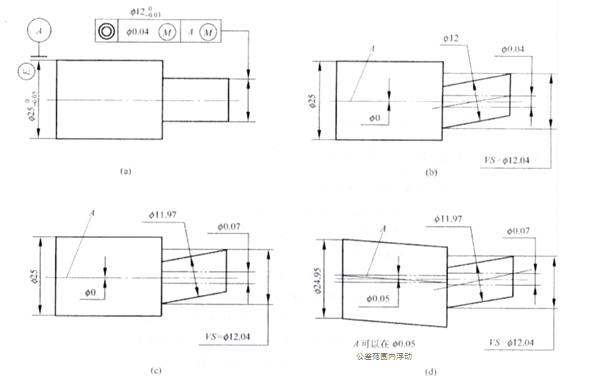

Isibalo sibonisa ukubekezelelana kokuqondisa kwe-eksisi, okuhambisana nesidingo esiphezulu somzimba.Uma i-shaft isesimweni esiqinile esiphezulu, ukubekezelelana kokuqondile kwe-eksisi yayo ngu-Ф0.1mm (Umfanekiso b).Kodwa-ke, uma usayizi wangempela we-shaft uchezuka esimweni sawo esiphezulu esiqinile, iphutha elivumelekile lokuqondisa f le-eksisi yalo linganyuswa ngokufanele.Umdwebo wendawo yokubekezelelana onikezwe kuMfanekiso C ubonisa ubudlelwano obuhambisanayo.

Ububanzi be-shaft kufanele bube phakathi kwebanga lika-Ф19.7mm ukuya ku-Ф20mm, kube nomkhawulo omkhulu ongu-Ф20.1mm.Ukuze uhlole ikhwalithi ye-shaft, qala kala uhlaka lwayo oluyisilinda ngokumelene negeji yendawo evumelana nobukhulu bomngcele osebenza ngokomzimba omkhulu ongu-Ф20.1mm.Bese, sebenzisa indlela enamaphuzu amabili ukukala usayizi wangempela wendawo we-shaft futhi uqinisekise ukuthi iwela ngaphakathi kobukhulu bomzimba obamukelekayo.Uma izilinganiso zihlangabezana nalezi zindlela, i-shaft ingathathwa njengefanelekile.

Umdwebo oguquguqukayo wendawo yokubekezelela ubonisa ukuthi uma usayizi wangempela wehla ukusuka kusimo esiqinile esiphezulu ngo-Ф20mm, iphutha elivumelekile lokuqondisa inani lika-f livunyelwe ukukhula ngokufanele.Kodwa-ke, ukukhuphuka okuphezulu akufanele kudlule ukubekezelelana kwe-dimensional.Lokhu kwenza ukuguqulwa kokubekezelelana kwe-dimensional kube ukuma nokubekezelelana kwesikhundla.

2) Izidingo ezibuyiseleka emuva zisetshenziselwa izidingo eziphezulu zebhizinisi

Uma imfuneko yokubuyisela emuva isetshenziswa esicelweni esiphezulu sokuqina, i-contour yangempela yesici esilinganiswayo kufanele ihambisane nomkhawulo wayo osebenzayo wokuqina.Uma usayizi wangempela uchezuka kusayizi omkhulu oqinile, iphutha lejometri livunyelwe ukweqa inani elinikeziwe lokubekezelela ijometri.Ukwengeza, uma iphutha lejiyomethri lingaphansi kwevelu yomehluko wejiyomethri enikeziwe kusimo esiqinile esiphezulu, usayizi wangempela ungase futhi udlule ubukhulu bobukhulu bobukhulu besimo esiqinile, kodwa umkhawulo oweqile ovunyelwe uwukufana kobukhulu kokubekezelela kwangaphambili kanye nokubekezelela kwejometri okunikeziwe. okwakamuva.

Umdwebo A uwumfanekiso wokusetshenziswa kwezidingo ezihlehliswayo zesidingo esiphezulu esiqinile.I-eksisi kufanele yanelise i-d fe ≤ Ф20.1mm, Ф19.7 ≤ d al ≤ Ф20.1mm.

Ifomula engezansi ichaza ukuthi uma usayizi wangempela we-shaft uchezuka kusukela kusimo esiqinile esiphezulu ukuya esimweni esiqinile esincane, iphutha lokuqondisa kwe-eksisi lingafinyelela inani eliphakeme, elilingana nenani lokubekezelela ukuqondisa elingu-0.1mm elinikezwe emdwebeni wokuhlanganisa ukubekezelela usayizi shaft 0.3mm.Lokhu kubangela isamba esingu-Ф0.4mm (njengoba kukhonjisiwe kuMfanekiso c).Uma inani lephutha lokuqondisa kwe-eksisi lingaphansi kwenani lokubekezelela elingu-0.1mm elinikezwe emdwebeni, liyi-Ф0.03mm, futhi usayizi walo wangempela ungaba mkhulu kunobukhulu bomzimba obuphelele, ufinyelele ku-Ф20.07mm (njengoba kuboniswe kuMfanekiso b).Uma iphutha lokuqondisa liyiziro, ubukhulu balo bangempela bungafinyelela inani eliphakeme, elilingana nobukhulu bomngcele osebenzayo obungokomzimba obungu-Ф20.1mm, ngaleyo ndlela ihlangabezane nemfuneko yokuguqula ukubekezelelana kwejiyomethri kube ukubekezelelana kwe-dimensional.Umdwebo c uwumdwebo oguquguqukayo obonisa indawo yokubekezelela yobudlelwano obuchazwe ngenhla.

Ngesikhathi sokuhlolwa, ububanzi bangempela be-shaft buqhathaniswa negeji yokuma ephelele, eklanywe ngokusekelwe kusayizi omkhulu womngcele osebenzayo osebenzayo ongu-20.1mm.Ukwengeza, uma ubukhulu bangempela be-shaft, njengoba kulinganiswa kusetshenziswa indlela yamaphuzu amabili, bukhulu kunobukhulu obuncane bomzimba obungu-19.7mm, khona-ke ingxenye ibhekwa njengefanelekile.

3) Izimfuneko eziphezulu zebhizinisi ziyasebenza kuzici zedatha

Lapho usebenzisa izimfuneko eziphezulu zokuqina kuzici zedatha, i-datum kufanele ihambisane nemingcele ehambisanayo.Lokhu kusho ukuthi uma usayizi wesenzo sangaphandle wesici se-datum ehluka kusayizi womngcele ohambisanayo, ingxenye yedatha ivunyelwe ukuhamba ngaphakathi kobubanzi obuthile.Ububanzi obuntantayo bulingana nomehluko phakathi kosayizi wesenzo sangaphandle wesici sedatha kanye nosayizi womngcele ohambisanayo.Njengoba i-elementi ye-datum ichezuka kusimo sebhizinisi esincane, ububanzi bayo obuntantayo buyanda kuze kube yilapho bufinyelela ubuningi.

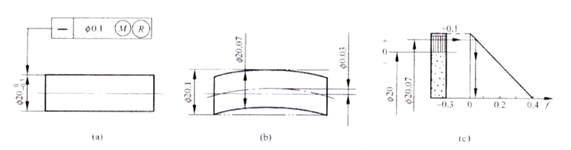

Umfanekiso A ubonisa ukubekezelelana kwe-coaxiality kwe-eksisi yendilinga yangaphandle ukuya eksisi yendilinga yangaphandle.Ama-elementi akaliwe nama-elementi e-datum asebenzisa izimfuneko ezibonakalayo eziphezulu ngesikhathi esisodwa.

Uma i-elementi isesimweni sayo esiphezulu esiqinile, ukubekezelelana kwe-coaxiality kwe-axis yayo ku-datum A kungu-Ф0.04mm, njengoba kuboniswe kuMfanekiso B. I-eksisi elinganisiwe kufanele yanelise d fe≤Ф12.04mm, Ф11.97≤d al≤Ф12mm .

Uma i-elementi encane ikalwa, kuvunyelwe ukuthi iphutha le-coaxiality le-eksisi yalo lifinyelele inani eliphezulu.Leli nani lilingana nesamba sokubekezelelana okubili: ukubekezelelana kwe-coaxiality okungu-0.04mm okucaciswe emdwebeni kanye nokubekezelelana kwe-dimensional kwe-eksisi, okungu-Ф0.07mm (njengoba kuboniswe kuMfanekiso c).

Lapho i-axis ye-datum isemngceleni ophezulu wenyama, ngosayizi wangaphandle we-Ф25mm, ukubekezelela i-coaxiality okunikezwayo emdwebeni kungaba ngu-Ф0.04mm.Uma usayizi wangaphandle wedatha wehlela kusayizi womzimba omncane ongu-Ф24.95mm, i-axis yedatha ingantanta ngaphakathi kokubekezelela kobukhulu okungu-Ф0.05mm.Uma i-axis isesimweni sokuntanta ngokwedlulele, ukubekezelela i-coaxiality kukhuphukela kunani lokubekezelela ubukhulu bedatum elingu-Ф0.05mm.Ngenxa yalokho, lapho izakhi ezilinganisiwe nezedatha zisesimweni esiqinile esincane ngesikhathi esifanayo, iphutha eliphezulu le-coaxiality lingafinyelela ku-Ф0.12mm (Umfanekiso d), okuyisamba esingu-0.04mm sokubekezelelana kwe-coaxiality, 0.03mm ngokubekezelela kwe-datum dimensional kanye no-0.05mm wokubekezelelana okuntantayo kwe-axis ye-datum.

6. Izidingo ezincane zebhizinisi kanye nezidingo zabo zokuhlehla

Uma ubona isithombe sophawu esimakwe ngemva kwevelu yokubekezelelana noma uhlamvu lwedatha ebhokisini lokubekezelela ijiyomethri emdwebeni, kubonisa ukuthi isici esilinganisiwe noma isici se-datum kufanele sihlangabezane nezidingo zomzimba ezincane, ngokulandelana.Ngakolunye uhlangothi, uma kukhona uphawu ngemva kwevelu yokubekezelela kwejometri yento elinganisiwe, kusho ukuthi imfuneko ehlehliswayo isetshenziselwa imfuneko encane yebhizinisi.

1) Izidingo ezincane zebhizinisi ziyasebenza ezidingweni ezingaphansi kokuhlolwa

Uma usebenzisa imfuneko encane yebhizinisi ye-elementi elinganisiwe, uhlaka lwangempela lwe-elementi akufanele ludlule umngcele walo osebenzayo kunoma ibuphi ubude obunikeziwe.Ukwengeza, usayizi wangempela wendawo we-elementi akufanele weqe umkhawulo noma usayizi omncane webhizinisi.

Uma ubuncane bemfuneko eqinile busetshenziswa esicini esilinganisiwe, inani lokubekezelela ijiyomethri linikezwa uma isici sisesimweni esiqinile esiyisisekelo.Kodwa-ke, uma i-contour yangempela yesici ichezuka kusayizi wayo omncane oqinile, inani lephutha lomumo nendawo lingadlula inani lokubekezelela elinikezwe esimweni esiqinile esincane.Ezimweni ezinjalo, usayizi osebenzayo wesici esilinganisiwe akufanele udlule usayizi womngcele oqinile, osebenzayo.

2) Izidingo ezibuyiseleka emuva zisetshenziselwa izidingo ezincane zebhizinisi

Uma usebenzisa imfuneko ebuyiseleka emuva esicelweni esincane esiqinile, uhlaka lwangempela lwesici esilinganisiwe akufanele ludlule umkhawulo walo oyisisekelo oqinile, osebenzayo kunoma ibuphi ubude obunikeziwe.Ukwengeza, usayizi wayo wangempela wendawo akufanele weqe ubukhulu bosayizi oqinile.Ngaphansi kwalezi zimo, akukhona nje ukuthi iphutha lejiyomethri livunyelwe ukweqa inani lokubekezelela ijiyomethri elinikezwe esimweni somzimba esincane lapho usayizi wangempela wesici esilinganisiwe uchezuka kusayizi womzimba omncane, kodwa futhi livunyelwe ukweqa ubuncane bosayizi womzimba lapho usayizi wangempela uhlukile, inqobo nje uma iphutha lejiyomethri lincane kunevelu enikeziwe yokubekezelela ijometri.

Icnc omshiniizimfuneko zokuqina okuncane nokuhlehliswa kwayo kufanele kusetshenziswe kuphela lapho ukubekezelela kwejiyomethri kusetshenziswa ukulawula isici esihlobene sesikhungo.Kodwa-ke, ukuthi uzosebenzisa lezi zidingo noma cha kuncike ezimfuneko zokusebenza ezithile zento.

Uma inani elinikeziwe lokubekezelela ijiyomethri liyiziro, izimfuneko eziqinile eziphezulu (ubuncane) kanye nezidingo zazo ezihlehliswayo zibizwa ngokuthi ukubekezelelana kwejiyomethri eyiziro.Kuleli qophelo, imingcele ehambisanayo izoshintsha kuyilapho ezinye izincazelo zihlala zingashintshiwe.

7. Ukunqunywa kwamanani okubekezela kwejometri

1) Ukunqunywa komumo womjovo kanye namanani okubekezelela isikhundla

Ngokuvamile, kunconywa ukuthi amanani okubekezelelana kufanele alandele ubudlelwano obuthile, nokubekezelelana komumo kube kuncane kunokubekezelela isikhundla kanye nokubekezelelana kobukhulu.Kodwa-ke, kubalulekile ukuqaphela ukuthi ezimweni ezingavamile, ukubekezelelana okuqondile kwe-axis ye-shaft slender kungase kube kukhulu kakhulu kunokubekezelelana kwe-dimensional.Ukubekezelelana kwesikhundla kufanele kufane nokubekezelelana kwe-dimensional futhi kuvame ukuqhathaniswa nokubekezelelana kwe-symmetry.

Kubalulekile ukuqinisekisa ukuthi ukubekezelelana kokuma kuhlale kukhulu kunokubekezela kokuma.Ukubekezelela indawo kungase kuhlanganise izidingo zokubekezelelana kokuma, kodwa okuphambene akulona iqiniso.

Ngaphezu kwalokho, ukubekezelelana okuphelele kufanele kube kukhulu kunokubekezelelana komuntu ngamunye.Isibonelo, ukubekezelela isilinda endaweni yesilinda kungaba kukhulu noma kulingane nokubekezelelana kokuqondisa kokuzungeza, umugqa oyinhloko, kanye ne-eksisi.Ngokufanayo, ukubekezelelana kokucaba kwendiza kufanele kube kukhulu noma kulingane nokubekezelelana kokuqondile kwendiza.Okokugcina, ukubekezelela okuphelele kokugijima kufanele kube kukhulu kunokukhishwa kwe-radial circular, ukujikeleza, i-cylindricity, ukuqondisa komugqa oyinhloko kanye ne-axis, nokubekezelelana kwe-coaxiality okuhambisanayo.

2) Ukunqunywa kwamanani angabonisiwe okubekezelela ijometri

Ukuze wenze imidwebo yobunjiniyela ibe mfushane futhi icace, kuyakhethwa ukukhombisa ukubekezelelana kwejiyomethri emidwebeni yokunemba kwejometri okulula ukuqinisekisa ekucubunguleni ithuluzi lomshini jikelele.Ngezakhi izidingo zazo zokubekezelelana kwefomu zingashiwongo ngokuqondile emdwebeni, ukunemba kwefomu nendawo nakho kuyadingeka.Sicela ubhekisele emithethweni yokusetshenziswa kwe-GB/T 1184. Ukudweba izethulo ngaphandle kwamanani okubekezelelana kufanele kuphawulwe kokunamathiselwe kwebhulokhi lesihloko noma kuzidingo zobuchwepheshe kanye nemibhalo yezobuchwepheshe.

Izinsimbi eziyisipele ezisezingeni eliphezulu,izingxenye zokugaya, futhiizingxenye eziphendulwe yinsimbizenziwa eChina, Anebon.Imikhiqizo ye-Anebon ithole ukuqashelwa okwengeziwe okuvela kumakhasimende akwamanye amazwe futhi yasungula ubudlelwano besikhathi eside nokubambisana nawo.I-Anebon izohlinzeka ngesevisi engcono kakhulu yawo wonke amakhasimende futhi yamukele abangane ngobuqotho ukuthi basebenze ne-Anebon futhi basungule izinzuzo ezifanayo ndawonye.

Isikhathi sokuthumela: Apr-16-2024