Kurongeka kwemechanical parts 'geometric parameters kunokanganiswa nezvose zviri zviviri dimensional kukanganisa uye kukanganisa kwechimiro.Mechanical chikamu madhizaini anowanzo tsanangura kushivirira kwedimensional uye kushivirira kwejometri panguva imwe chete.Kunyangwe paine misiyano uye kubatana pakati pezviviri izvi, izvo zvinodiwa nekururama zve geometric parameters zvinotarisa hukama pakati peiyo geometric kushivirira uye dimensional kushivirira, zvichienderana nemamiriro ekushandiswa kwechikamu.

1. Misimboti yekushivirira yakati wandei maererano nehukama pakati pekushivirira kwedimensional uye kushivirira kwejometri.

Kushivirira misimboti mirau inosarudza kana dimensional tolerances uye geometric tolerances inogona kushandiswa zvakasiyana kana kwete.Kana kushivirira uku kusingagoni kushandurudzwa kune mumwe nemumwe, kunoonekwa seyakazvimirira nheyo.Nekune rumwe rutivi, kana kutendeuka kuchibvumidzwa, itsika inowirirana.Misimboti iyi inoiswazve muzvikamu zvinosanganisirwa zvinodiwa, zvinonyanya kukosha zvesangano, zvidiki zvinodiwa nesangano, uye zvinodzokororwa zvinodiwa.

2. Basic terminology

1) Saizi yemunharaunda chaiyo D al, d al

Chinhambwe chinoyerwa pakati pemapoinzi maviri anowirirana pane chero chikamu chakajairika chechinhu chaicho.

2) External chiito saizi D fe, d fe

Tsanangudzo iyi inoreva dhayamita kana hupamhi hwenzvimbo hombe yakanaka iyo yakabatana nekunze kune chaiyo yemukati yepamusoro kana diki diki yakanaka iyo yakabatana nekunze kune chaiyo yekunze yekunze pakureba kwakapihwa kwechinhu chiri kuyerwa.Kune zvinosanganisirwa maficha, axis kana ndege yepakati yenzvimbo yakakodzera inofanirwa kuchengetedza hukama hwejometri hwakapihwa nedhirowa ine datum.

3) In vivo chiito saizi D fi, d fi

Uyo dhayamita kana hupamhi hwenzvimbo diki yakanakira mukubata kwemuviri neiyo chaiyo yemukati nzvimbo kana yakakura yakanaka nzvimbo pakubata kwemuviri neiyo yekunze chaiyo pahurefu hwakapihwa hwechinhu chiri kuyerwa.

4) Yakakura yemuviri inoshanda saizi MMVS

Hukuru hwemuviri hunoshanda hunoreva hukuru hwekunze hwekuita mudunhu umo hunoshanda zvakanyanya mumuviri.Kana zvasvika kune mukati memukati, iyo yakakura inoshanda yakasimba saizi inoverengerwa nekubvisa iyo geometric kushivirira kukosha (inoratidzwa nechiratidzo) kubva kune yakanyanya kusimba saizi.Kune rumwe rutivi, nokuda kwekunze kwekunze, iyo yakawanda inoshanda yakasimba saizi inoverengerwa nekuwedzera geometric tolerance value (inoratidzwawo nechiratidzo) kusvika kuhukuru hwakasimba hwakasimba.

MMVS= MMS± T-chimiro

Muchidimbu, nzvimbo yekunze inomiririrwa nechiratidzo "+", uye mukati inomiririrwa ne "-" chiratidzo.

5) Minimum yemuviri inoshanda saizi LMVS

Hukuru hwehudiki hunoshanda hwechinhu hunoreva saizi yemuviri kana iri muhushoma hunoshanda.Kana tichitaura nezvemukati wemukati, hushoma hwemuviri hunoshanda saizi inoverengerwa nekuwedzera iyo geometric kushivirira kukosha kune diki saizi yemuviri (sezvinoratidzwa nechiratidzo mumufananidzo).Kune rumwe rutivi, kana tichitaura nezvekunze kwekunze, hukuru hunobudirira hwemuviri hunoverengwa nekubvisa kukosha kwejometri yekushivirira kubva pahukuru hwemuviri (inoratidzwawo nechiratidzo mumufananidzo).

LMVS= LMS ±t-chimiro

Muchidimbu, nzvimbo yemukati inotora "+" chiratidzo, uye kunze kunotora "-" chiratidzo.

3. Nheyo yekuzvimirira

Nheyo yekuzvimiririra ndeyekushivirira musimboti unoshandiswa mukugadzira engineering.Izvi zvinoreva kuti kushivirira kwejometri uye kushivirira kwedimensional kunotsanangurwa mudhirowa kwakaparadzana uye hakuna hukama kune mumwe nemumwe.Kushivirira kwese kunofanirwa kuzadzisa zvavanoda zvakazvimiririra.Kana chimiro chekushivirira uye kushivirira kwedimensional kuchitevera musimboti wekuzvimirira, hunhu hwavo hwenhamba hunofanirwa kucherechedzwa padhirowa zvakasiyana pasina mamwe mavanga.

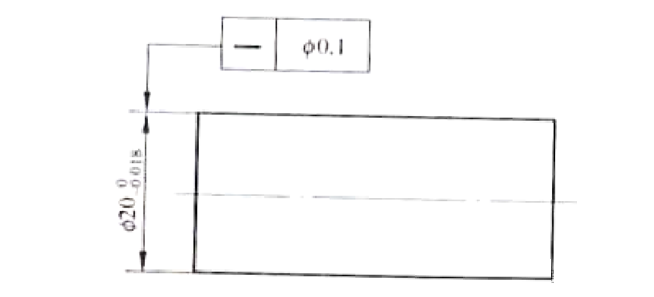

Kuti uve nechokwadi chehutano hwezvikamu zvakaratidzwa mumufananidzo, zvakakosha kufunga nezve kushivirira kwechidimbu cheshaft dhayamita Ф20 -0.018 uye kururamisa kushivirira kweaxis Ф0.1 zvakasununguka.Izvi zvinoreva kuti chiyero chimwe nechimwe chinofanira kusangana nezvinodiwa zvekugadzira pachayo, uye saka dzinofanirwa kuongororwa zvakasiyana.

Iyo shaft dhayamita inofanira kuwira pakati pehuwandu hweФ19.982 kusvika 20, nekanganiso yakatenderwa yekururama pakati pehuwandu hweФ0 kusvika 0.1.Kunyangwe iyo yakakura kukosha kweiyo shaft dhayamita saizi chaiyo inogona kusvika kuФ20.1, haidi kudzorwa.Nheyo yekuzvimirira inoshanda, zvichireva kuti dhayamita haiitirwe kuongororwa kwakadzama.

4. Nheyo yekushivirira

Kana mufananidzo wechiratidzo ukabuda mushure meiyo dimensional muganho kutsauka kana kushivirira zone kodhi yechinhu chimwe chete padhirowa, zvinoreva kuti chinhu chimwe chete chine kushivirira zvinodiwa.Kuti usangane nemidziyo inodiwa, iyo chaiyo ficha inofanirwa kuenderana neyakakura muganho wemuviri.Mune mamwe mazwi, saizi yekunze yechiitiko haifanire kudarika muganhu wayo wepamuviri, uye saizi chaiyo yenzvimbo haifanire kunge idiki pane hudiki hwayo hwemuviri.

Huwandu hunotaridza kuti kukosha kwe dfe kunofanirwa kunge kuri pasi kana kuenzana ne20mm, ukuwo kukosha kwedal kuchifanirwa kunge kwakakura kupfuura kana kuenzana ne19.70mm.Panguva yekuongorora, iyo cylindrical pamusoro ichaonekwa inokodzera kana ichigona kupfuura neyakakwana-chimiro geji ine dhayamita ye20mm uye kana iyo yese yenzvimbo chaiyo saizi yakayerwa pamapoinzi maviri yakakura kupfuura kana yakaenzana ne19.70mm.

Chinodiwa chekushivirira chinodiwa chekushivirira icho panguva imwe chete chinodzora saizi chaiyo uye zvikanganiso zvechimiro mukati meiyo dimensional kushivirira renji.

5. Maximum entity zvinodiwa uye yavo reversibility zvinodiwa

Pakudhirowa, kana mufananidzo wechiratidzo uchitevera kukosha kwekushivirira mubhokisi rejometri rekushivirira kana tsamba yereferensi, zvinoreva kuti chinhu chakayerwa uye chinongedzo chinotora izvo zvinonyanya kudiwa zvemuviri.Ngatitii mufananidzo wakanyorwa mushure mechiratidzo chemufananidzo mushure meiyo geometric kushivirira kukosha kweiyo yakayerwa chinhu.Muchiitiko ichocho, zvinoreva kuti chinogadziriswa chinodiwa chinoshandiswa kune yakanyanya kusimba inodiwa.

1) Iyo yakanyanya kudiwa chinodiwa inoshanda kune akayerwa zvinhu

Pakuyera chimiro, kana chinodiwa chakanyanya kusimba chikaiswa, kukosha kweiyo geometric kushivirira kwechinhu kuchapihwa chete kana chimiro chiri muhukuru hwayo hwakasimba.Nekudaro, kana iyo contour chaiyo yechinhu ichitsauka kubva kune yayo yakanyanya kusimba mamiriro, zvichireva kuti saizi chaiyo yenzvimbo yakasiyana nehukuru hwakasimba hwakasimba, chimiro uye chinzvimbo chikanganiso kukosha chinogona kudarika kukosha kwekushivirira kwakapihwa mune yakanyanya kusimba mamiriro, uye iyo huwandu hwakawandisa huchaenzana nehupamhi hwakasimba.Zvakakosha kuziva kuti kushivirira kwedimensional yechinhu chakayerwa kunofanirwa kunge kuri mukati mehupamhi hwayo uye hushoma saizi yemuviri, uye saizi yaro chaiyo haifanire kudarika hukuru hwayo hwemuviri.

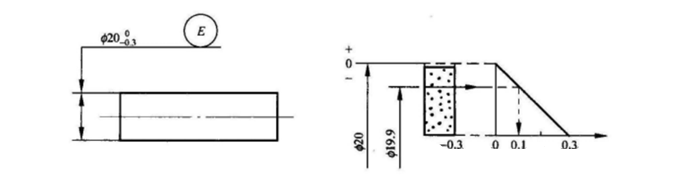

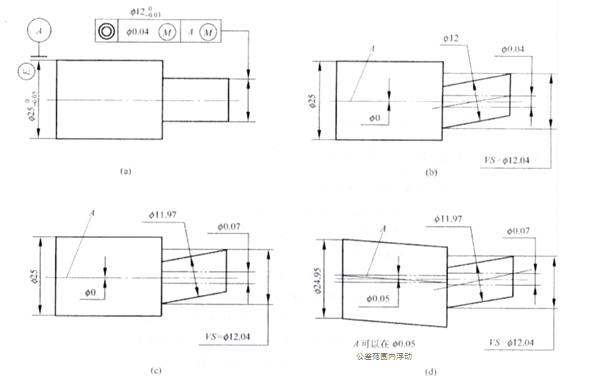

Iyo nhamba inoratidza kushivirira kwakatwasuka kweaxis, iyo inonamatira kune yakanyanya kudiwa kwemuviri.Kana iyo shaft iri mune yayo yakanyanya kusimba mamiriro, iyo yakatwasuka kushivirira kweaxis yayo ndeye Ф0.1mm (Mufananidzo b).Nekudaro, kana saizi chaiyo yeshaft ikatsauka kubva kune yakanyanya kusimba mamiriro, iyo inotenderwa yekururamisa kukanganisa f yeaxis yayo inogona kuwedzerwa zvinoenderana.Iyo yekushivirira dhizaini yakapihwa muMufananidzo C inoratidza hukama hunoenderana.

Iyo dhayamita yeshaft inofanira kunge iri mukati mehupamhi hwe Ф19.7mm kusvika Ф20mm, ine muganho mukuru we Ф20.1mm.Kuti utarise kunaka kweshaft, tanga wayera cylindrical outline pakatarisana nenzvimbo yegeji inoenderana nehukuru hwemuviri hunoshanda hwemuganho saizi yeФ20.1mm.Zvadaro, shandisa nzira mbiri-mapoinzi kuyera saizi chaiyo yenzvimbo yeshaft uye ive nechokwadi chekuti inowira mukati meiyo inogamuchirwa zviyero zvemuviri.Kana zviyero zvikasangana nemaitiro aya, shaft inogona kunzi inokodzera.

Iyo yekushivirira dhizaini yedhizaini inoratidza kuti kana saizi chaiyo inodzikira kubva kune yakanyanya kusimba mamiriro ne Ф20mm, iyo inotenderwa yekururamisa kukanganisa f kukosha inobvumidzwa kuwedzera zvinoenderana.Nekudaro, iyo yakanyanya kuwedzera haifanirwe kudarika dimensional kushivirira.Izvi zvinogonesa kushandurwa kwedimensional kushivirira kuita chimiro uye chinzvimbo kushivirira.

2) Reversible zvinodiwa zvinoshandiswa kune yakanyanya mubatanidzwa zvinodiwa

Kana icho chinodiwa chekudzoreredza chikaiswa kune yakanyanya kusimba chinodiwa, iyo chaiyo contour yechinhu chiri kuyerwa inofanirwa kuenderana neyakaomesesa kusimba kwayo inoshanda muganho.Kana saizi chaiyo ikatsauka kubva pahukuru hwakasimba saizi, chikanganiso chejometri chinotenderwa kudarika yakapihwa geometric tolerance value.Pamusoro pezvo, kana kukanganisa kwejometri kuri kushoma pane yakapihwa geometric musiyano kukosha mune yakanyanya kusimba mamiriro, saizi chaiyo inogona zvakare kudarika yakanyanya kusimba-yenyika zviyero, asi iyo yakanyanya kubvumidzwa yakawandisa idimensional commonality kune yekutanga uye yakapihwa geometric tolerance. zvekupedzisira.

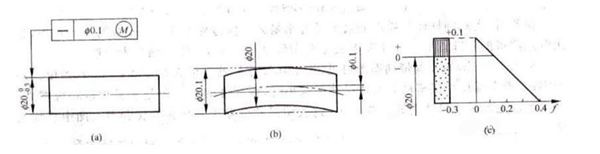

Mufananidzo A mufananidzo wekushandiswa kwezvinoda kudzoserwa kune yakanyanya kusimba inodiwa.Axis inofanira kugutsa d fe ≤ Ф20.1mm, Ф19.7 ≤ d al ≤ Ф20.1mm.

Formula iri pazasi inotsanangura kuti kana saizi chaiyo yeshaft ikatsauka kubva padanho rakasimba kusvika padiki yakasimba, kukanganisa kwekutwasuka kweaxis kunogona kusvika pahukoshi hwepamusoro, hunoenzana nekururama kwekushivirira kukosha kwe0.1mm yakapihwa mudhirowa kuwedzera. saizi yekushivirira kweshaft ye0.3mm.Izvi zvinoguma nehuwandu hweF0.4mm (sezvinoratidzwa mumufananidzo c).Kana kukosha kwekukanganisika kweaxis kuri kushoma pane kushivirira kukosha kwe0.1mm yakapihwa padhirowa, iri Ф0.03mm, uye saizi yayo chaiyo inogona kunge yakakura kupfuura yakakura saizi yemuviri, inosvika Ф20.07mm (sezvinoratidzwa mumufananidzo. b).Kana kukanganisa kwekururama kuri zero, saizi yaro chaiyo inogona kusvika pakukosha kwepamusoro, iyo yakaenzana nehukuru hwayo hwemuganho hunoshanda hwe Ф20.1mm, nekudaro kusangana nezvinodiwa zvekushandura kushivirira kwejometri kuita kushivirira kwedimensional.Mufananidzo c dhayagiramu ine simba inoratidzira nzvimbo yekushivirira yehukama hwakatsanangurwa pamusoro.

Munguva yekuongorora, iyo shaft chaiyo dhayamita inofananidzwa neyakaomesesa chinzvimbo geji, iyo yakagadzirirwa zvichienderana nehupamhi hwemuviri hunoshanda muganho saizi ye20.1mm.Pamusoro pezvo, kana saizi chaiyo yeshaft, sekuyerwa uchishandisa nzira yemapoinzi maviri, yakakura kupfuura diki yehukuru hwemuviri hwe19.7mm, ipapo chikamu chinoonekwa sechakakodzera.

3) Maximum entity zvinodiwa zvinoshanda kune datum maficha

Paunenge uchishandisa zvakanyanya kusimba zvinodiwa kune datum maficha, iyo datum inofanirwa kuenderana nemiganhu inoenderana.Izvi zvinoreva kuti kana saizi yechiitiko chekunze cheiyo datum chimiro chakasiyana nehukuru hwayo hwemuganho, iyo datum element inotenderwa kufamba mukati meimwe renji.Iyo inoyangarara yakaenzana nemusiyano uripo pakati pehukuru hwekuita kwekunze kweiyo datum element uye inoenderana muganho saizi.Sezvo iyo datum element inotsauka kubva kune yakaderera entity mamiriro, iyo inoyangarara siyana inowedzera kusvika yasvika pakakwirira.

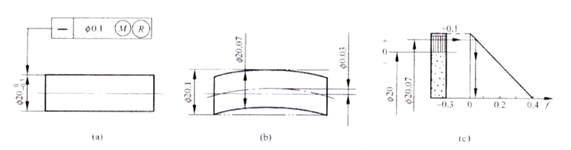

Mufananidzo A unoratidza kushivirira kweaxisi yedenderedzwa rekunze kune akiso yedenderedzwa rekunze.Izvo zvakayerwa zvinhu uye datum zvinhu zvinotora izvo zvakanyanya zvemuviri zvinodiwa panguva imwe chete.

Kana chinhu chacho chiri muhukuru hwayo hwakasimba, kushivirira kwekubatana kweaxis yayo kune datum A ndeye Ф0.04mm, sezvinoratidzwa mumufananidzo B. Iyo yakayerwa axis inofanira kugutsa d fe≤Ф12.04mm, Ф11.97≤d al≤Ф12mm .

Kana chinhu chidiki chiri kuyerwa, zvinotenderwa kuti coaxiality kukanganisa kweakisi yayo isvike pakukosha kwepamusoro.Ukoshi uhwu hwakaenzana nehuwandu hwekushivirira kuviri: iyo coaxiality kushivirira ye0.04mm inotsanangurwa mukudhirowa uye dimensional kushivirira kweakisi, iyo Ф0.07mm (sezvinoratidzwa mumufananidzo c).

Kana iyo axis yedatum iri pamuganho wepamusoro wemuviri, nehukuru hwekunze hweФ25mm, iyo yakapihwa coaxiality kushivirira padhirowa inogona kuve Ф0.04mm.Kana saizi yekunze yedatum yakadzikira kusvika kudiki saizi yemuviri yeФ24.95mm, iyo datum axis inogona kuyangarara mukati meiyo dimensional kushivirira kweФ0.05mm.Kana axis iri mukuyangarara yakanyanyisa, iyo coaxiality kushivirira inowedzera kune iyo datum dimensional kushivirira kukosha kwe Ф0.05mm.Nekuda kweizvozvo, kana zviyero zvakayerwa uye datum zviri muhushoma hwakasimba mamiriro panguva imwe chete, iyo yakanyanya coaxiality kukanganisa inogona kusvika kuФ0.12mm (Mufananidzo d), inova huwandu hwe0.04mm yekushivirira kwekubatana, 0.03mm. yedatum dimensional kushivirira uye 0.05mm yedatum axis inoyangarara kushivirira.

6. Zvidiki zvinodikanwa zvenhengo uye zvavanoda kudzoreredza

Kana iwe ukaona mufananidzo wechiratidzo wakanyorwa mushure mekushivirira kukosha kana datum tsamba mubhokisi rejometri rekushivirira pane dhirowa, zvinoratidza kuti iyo yakayerwa chinhu kana datum chinhu chinofanira kusangana nezvinodiwa zvishoma zvemuviri, zvichiteerana.Kune rimwe divi, kana paine chiratidzo mushure meiyo geometric kushivirira kukosha kweyero yakayerwa, zvinoreva kuti inodzoreredza chinodiwa chinoshandiswa kune diki chidimbu chinodiwa.

1) Zvidiki zvinodiwa zvenhengo zvinoshanda kune zvinodiwa pasi pebvunzo

Paunenge uchishandisa iyo yepasi inodiwa yechinhu chakayerwa, iyo chaiyo yechinhu hachifanirwe kudarika muganho unoshanda pane chero hurefu hwakapihwa.Pamusoro pezvo, saizi chaiyo yenzvimbo yechinhu haifanirwe kudarika iyo yakakura kana diki saizi yechinhu.

Kana iyo shoma yakasimba inodiwa ikaiswa kune yakayerwa ficha, iyo geometric tolerance value inopiwa kana chimiro chiri mudikidiki solid state.Zvisineyi, kana iyo contour chaiyo yechinhu ichitsauka kubva pahukuru hwayo hwakasimba, chimiro uye chinzvimbo chemhosho inogona kudarika kukosha kwekushivirira kunopiwa muhushoma hwakasimba.Mumamiriro ezvinhu akadaro, saizi inoshanda yechinhu chakayerwa haifanire kudarika hushoma hwayo hwakasimba, hunobudirira hwemuganhu.

2) Zvinodzoreredzwa zvinodikanwa zvinoshandiswa kune zvidiki zvinodiwa zvenhengo

Paunenge uchiisa chinodzoreredza chinodiwa kune hudiki hwakasimba chinodiwa, yakayerwa chimiro chaicho hachifanirwe kudarika chishoma chakasimba, chinoshanda muganhu pane chero hurefu hwakapihwa.Pamusoro pezvo, saizi yaro chaiyo haifanire kudarika yakakura yakasimba saizi.Pasi pemamiriro aya, kwete chete kukanganisa kwejometri kunobvumirwa kudarika kukosha kwejometri yekushivirira kunopiwa muhudiki hwemuviri apo saizi chaiyo yechinhu chakayerwa ichitsauka kubva paudiki hwesaizi yemuviri, asi zvakare inotenderwa kudarika diki diki saizi yemuviri kana. saizi chaiyo yakasiyana, chero geometric kukanganisa idiki pane yakapihwa geometric kushivirira kukosha.

Thecnc yakagadzirwazvinodikanwa zvehushoma hwakasimba uye kudzoreredzwa kwayo kunofanira kushandiswa chete kana iyo geometric kushivirira ichishandiswa kudzora yakabatana yepakati chimiro.Nekudaro, kuti kushandisa izvi zvinodiwa kana kwete zvinoenderana nezvinodiwa zvekuita zvechinhu.

Kana iyo yakapihwa geometric tolerance value iri zero, iyo yakanyanya (idiki) yakasimba zvinodiwa uye zvavanoda zvinodzoreredzwa zvinonzi zero geometric tolerances.Panguva ino, miganhu inoenderana ichachinja nepo dzimwe tsananguro dzichiramba dzisina kuchinjwa.

7. Kutsunga kwema geometric tolerance values

1) Kutsunga kwechimiro chejekiseni uye chinzvimbo chekushivirira kukosha

Kazhinji, zvinokurudzirwa kuti kushivirira tsika dzinofanira kutevera chaiyo hukama, nechimiro kushivirira kuva diki pane chinzvimbo kushivirira uye dimensional kushivirira.Nekudaro, zvakakosha kuti uzive kuti mumamiriro ezvinhu asina kujairika, kushivirira kwakatwasuka kweakisi ye slender shaft kungave kwakakura kupfuura kushivirira kwedimensional.Kushivirira kwechinzvimbo kunofanirwa kunge kwakafanana nekushivirira kwedimensional uye kunowanzo kufananidzwa nesymmetry tolerances.

Izvo zvakakosha kuve nechokwadi chekuti kushivirira kwenzvimbo kunogara kwakakura kupfuura kushivirira kwekutarisa.Kushivirira kwekumisikidza kunogona kusanganisira zvinodiwa zvekushivirira kwekutarisa, asi zvinopesana hazvisi zvechokwadi.

Uyezve, kushivirira kwakazara kunofanira kunge kwakakura kupfuura kushivirira kwega.Semuenzaniso, iyo cylindricity kushivirira yehumburumbira yepamusoro inogona kuve yakakura kupfuura kana kuenzana nekutwasanuka kushivirira kwekutenderera, mutsara wekutanga, uye axis.Saizvozvo, kushivirira kwendege kunofanirwa kuve kwakakura kudarika kana kuenzana nekururama kushivirira kwendege.Chekupedzisira, iyo yakazara runout kushivirira kunofanirwa kuve kwakakura kudarika radial denderedzwa runout, kutenderera, cylindricity, kutwasuka kweiyo prime line uye axis, uye inoenderana coaxiality kushivirira.

2) Kutsunga kwezvisina kuratidzwa geometric tolerance values

Kuti uite kuti madhirowa einjiniya ave mapfupi uye akajeka, isarudzo kuratidza kushivirira kwejometri pamifananidzo yekurongeka kweiyo geometric iri nyore kuve nechokwadi mune zvakajairika muchina wekushandisa.Kune zvinhu izvo zvinodikanwa zvekushivirira fomu zvisina kutaurwa zvakananga padhirowa, iyo fomu uye chimiro chechokwadi chinodiwa zvakare.Ndapota tarisai kumitemo yekushandiswa kweGB / T 1184. Kudhirowa zviratidziro pasina kushivirira kukosha kunofanirwa kucherechedzwa mumusoro we block block kana mune zvinodiwa zvehunyanzvi uye magwaro ehunyanzvi.

Yemhando yepamusoro auto spare parts,milling parts,uyesimbi-yakatendeuka zvikamuinogadzirwa muChina, Anebon.Zvigadzirwa zveAnebon zvakawedzera kucherechedzwa kubva kune vekunze vatengi uye vakagadzira hukama hwenguva refu uye hwekubatana navo.Anebon ichapa sevhisi yakanakisa kune wese mutengi uye nemoyo wese shamwari dzinogamuchira kuti dzishande neAnebon uye kumisa mabhenefiti pamwe chete.

Nguva yekutumira: Kubvumbi-16-2024