Tšusumetso ke eng?

Li-bearings ke likarolo tse tšehetsang shaft, tse sebelisetsoang ho tataisa motsamao oa ho potoloha ha shaft, le ho jara mojaro o fetisitsoeng ho tloha ho shaft ho ea foreiming.Li-bearings li sebelisoa haholo ebile li hloka likarolo tse tšehetsang le likarolo tsa mantlha indastering ea mechini.Ke likarolo tse tšehetsang tsa li-shafts tse potolohang kapa likarolo tse suthehang tsa mechini e fapaneng, hape ke likarolo tse tšehetsang tse itšetlehileng ka ho bilika ha 'mele e bilikang ho hlokomela ho potoloha ha enjene e kholo.Tse tsejoang e le manonyeletso a mochini.

Li-bearings li lokela ho aroloa joang?

Ho ea ka mefuta e fapaneng ea likhohlano ha koranta e sebetsa ho beng, li-bearings li arotsoe ka mekhahlelo e 'meli:

dibering tse thellang le dibering tse thellang.

-

Bere e hlakileng

Ho ea ka tataiso ea mojaro ho bering, li-bearings tse thellang li arotsoe ka mekhahlelo e meraro:①Radial bearing--ho jara mojaro oa radial, 'me tataiso ea mojaro e lebile bohareng ba shaft;

②Thrust bear——ho jara mojaro oa axial, 'me tsela ea mojaro e bapa le mola o bohareng oa shaft;

③Radial-thrust bear——ka nako e le ’ngoe e jara meroalo ea radial le axial.

Ho ea ka boemo ba khohlano, li-bearings tse thellang li arotsoe ka mekhahlelo e 'meli: li-bearings tse thellang tse sa khohlang le metsi a thellang.Ea pele e boemong ba khohlano e omileng kapa khohlano ea moeli, 'me ea morao-rao e maemong a mokelikeli.

-

rolling bear

(1) Ho ea ka tataiso ea mojaro oa ho roala, e ka aroloa ka:①Moroalo oa radial o jara boima ba radial haholo.

②Thrust bear e jara mojaro oa axial.

(2) Ho ea ka sebōpeho sa likarolo tse pota-potileng, e ka aroloa ka: li-ball bearings le li-roller bearings.Lintho tse bilikang ka har'a bering li na le mola o le mong le mola o habeli.

(3) Ho ea ka tataiso ea mojaro kapa sekhutlo sa lebitso le mofuta oa lintho tse kolohang, e ka aroloa ka:

1. Deep groove ball bearings.

2. Cylindrical rolara dibering.

3. Lithako tsa nale.

4. Li-bearings tsa bolo tse ikamahanyang le tsona.

5. Li-angular ball bearings.

6. Spherical rolara dibering.

7. Li-rolara tse tapered.

8. Hlakola li-angular ball bearings.

9. Hlakola libere tse chitja tsa rolara.

10. Hust tapered rolara dibering.

11. Ho phutha li-ball bearings.

12. Hlakola libere tsa rolara tsa cylindrical.

13. Hula li-bearings tsa nale.

14. Li-bearings tse kopantsoeng.

Li-bearings tse bilikang, ho na le ntlha kapa khokahanyo lipakeng tsa lintho tse bilikang le tsela ea peiso, 'me khohlano pakeng tsa tsona ke ho khohlakana.Ha lebelo le phahame, bophelo ba ho roala bo theoha haholo;ha mojaro o le moholo 'me tšusumetso e kholo, lintlha tsa ho beleha kapa mela e kopana.

Ho li-bearings tse thellang, ho na le kamano ea bokaholimo lipakeng tsa jenale le bering, le khohlano e thellang lipakeng tsa libaka tse hokahaneng.Sebopeho sa bering e thellang ke hore koranta e tsamaisana le sehlahla se behang;molao-motheo oa khetho ke ho etelletsa pele khetho ea li-bearings tse thellang, le ho sebelisa li-bearings tse thellang maemong a khethehileng.Khokahano e ka holimo e thellang;mohaho o khethehileng o hloka mohaho o moholo ka ho fetisisa, 'me litšenyehelo tsa ho thella li tlaase.

-

Li-bearings li arotsoe ka li-bearings tsa radial le li-thrust bearings ho latela tataiso ea ho jara kapa angle ea lebitso.

-

Ho ea ka mofuta oa ntho ea ho roala, e arotsoe ka: li-ball bearings, li-roller bearings.

-

Ho ea ka hore na e ka lumellana, e arotsoe ka: li-bearings tse ikemetseng, li-bearings tse sa lumellaneng (li-rigid bearings).

-

Ho ea ka palo ea mela ea li-rolling elements, e arotsoe ka: li-bearings tsa mela e le 'ngoe, li-bearings tse nang le mela e 'meli, le li-bearings tse ngata.

-

Ho ea ka hore na likarolo li ka aroloa, li arotsoe ka: li-bearings tse arohaneng le li-bearings tse sa arohaneng.

Ho phaella moo, ho na le lihlopha ka sebōpeho sa sebopeho le boholo.

Sengoliloeng sena haholo-holo se arolelana litšobotsi, liphapang le ts'ebeliso e ts'oanang ea li-bearings tse 14 tse tloaelehileng.

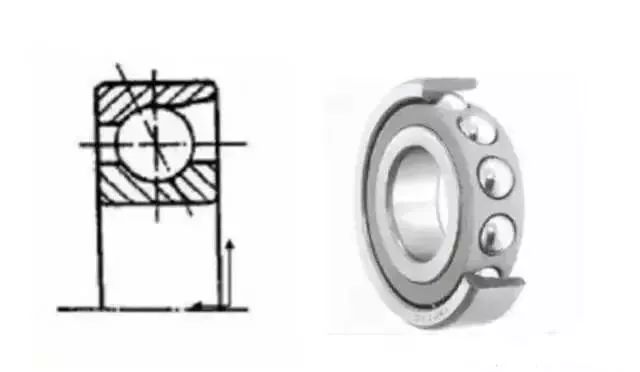

1. Li-angular ball bearings

Ho na le angle ea ho kopana pakeng tsa ferrule le bolo.Tsela e tloaelehileng ea ho kopana ke 15°, 30° le 40°.E kholoanyane angle ea ho kopana ke, matla a axial load a maholo.Ha angle ea ho kopana e le nyane, e ntle haholo bakeng sa ho potoloha ka lebelo le phahameng.Li-bearings tsa mela e le 'ngoe li ka jara mojaro oa radial le mojaro oa axial oa tsela e le 'ngoe.Ka sebopeho, li-bearings tse peli tse nang le mela e le 'ngoe ea li-angular tse kopantsoeng ka morao li arolelana lesale la ka hare le lesale la ka ntle, le khonang ho jara mojaro oa radial le bidirectional axial load.

Angular contact ball bearings

Sepheo se seholo:

Kholomo e le 'ngoe: sesebelisoa sa mochini oa spindle, enjene ea maqhubu a phahameng haholo, turbine ea khase, karohano ea centrifugal, lebili le lenyane la koloi e ka pele, pinion shaft e fapaneng.

Kholomo e habeli: pompo ea oli, sefutho sa Roots, compressor ea moea, phetisetso e fapaneng, pompo ea ente ea mafura, mochini oa khatiso.

2. Li-bearings tsa bolo tse ikamahanyang le tsona

Mela e 'meli ea libolo tsa tšepe, tsela ea peiso ea selikalikoe sa ka ntle ke mofuta oa selikalikoe se ka hare, kahoo e ka khona ho fetola tsela e fosahetseng ea shaft e bakoang ke ho kheloha kapa ho se lumellane ha shaft kapa khetla,' me ho beha sekoti se nang le sekoti ho ka ba bonolo. e kentsoeng mokoting ka ho sebelisa li-fasteners.mamella meroalo ea mahlaseli.

Boiketsi ba ho tsamaisa bolo

Kopo ea mantlha: mochini o etsang mapolanka, mochini o tsamaisang mochini oa masela, mochini o ikamahanyang le setulo.

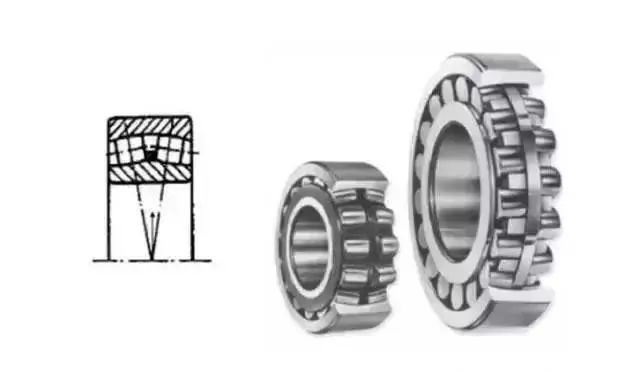

3. Spherical rolara dibering

Mofuta ona oa ho beleha o na le lirolara tse chitja lipakeng tsa lesale la ka ntle la tsela e chitja le lesale la ka hare la peiso e habeli.Ho ea ka mefuta e fapaneng ea ka hare, e arotsoe ka mefuta e mene: R, RH, RHA le SR.Setsi sa ho beleha se tsitsitse ebile se na le ts'ebetso ea ho ikamahanya le maemo, kahoo e ka khona ho fetola tsela e fosahetseng ea setsi sa shaft se bakoang ke ho kheloha kapa ho se lumellane ha shaft kapa shell, 'me e ka jara mojaro oa radial le bidirectional axial load.

Sebetsa sa rolara

Lisebelisoa tsa mantlha: mechini ea ho etsa pampiri, lisebelisoa tsa ho theola boima ba 'mele, li-axle tsa koloi ea terene, litulo tsa li-giarbox tsa leloala, litafole tse bilikang, li-crusher, li-skrini tse sisinyehang, mechini e hatisang, metjhini e etsang mapolanka, lisebelisoa tse fapaneng tsa liindasteri, li-bearings tse otlolohileng tse nang le litulo.

4. Ho itokisa ho tsamaisa rolara

Li-rollers tse chitja tsa mofuta ona oa ho beha li hlophisitsoe ka mokhoa o oblique.Hobane sebaka sa peiso sa lesale la setulo se chitja ebile se na le ts'ebetso ea ho ikamahanya le maemo, se ka lumella shaft hore e be le tšekamelo e itseng, 'me matla a axial a boima haholo.

Meroalo ea mahlaseli hangata e tlotsoa ka oli.

Li-bearings tsa spherical roller

Lisebelisoa tsa mantlha: lijenereithara tsa hydraulic, li-motor tse otlolohileng, li-propeller shafts bakeng sa likepe, lisebelisoa tsa ho theola li-screw bakeng sa mabili a roala, li-crane tsa tora, liloala tsa mashala, metjhini ea extrusion le metjhini ea ho etsa.

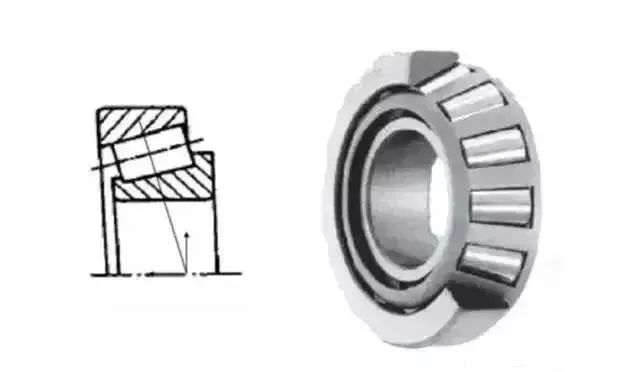

5. Li-rolara tse tapered

Mofuta ona oa ho beleha o na le li-rollers tsa cylindrical tse nang le truncated, 'me li-roller li tataisoa ke likhopo tse kholo tsa lesale la ka hare.Tlhōrō ea bokaholimo bo bong le bo bong ba bokaholimo ba lesale la ka hare la peiso, bokaholimo ba selikalikoe sa peiso, le bokaholimo ba rolara bo kopana moleng o bohareng oa bere ka moralo.ntlheng.Li-bearings tse nang le mela e le 'ngoe li ka jara meroalo ea mahlaseli le li-axial tsa tsela e le' ngoe, li-bearings tse nang le mela e 'meli li ka jara meroalo ea radial le li-axial tse peli,' me li loketse meroalo e boima le meroalo ea tšusumetso.

Tapered Roller Bearings

Sesebelisoa sa mantlha:Koloi: lebili le ka pele, lebili le ka morao, phetisetso, pinion shaft e fapaneng.Li-spindle tsa mochini, mechini ea kaho, mechini e meholo ea temo, lisebelisoa tsa phokotso ea lipalangoang tsa literene, melala ea melala le lisebelisoa tsa phokotso bakeng sa litsila.

Ke kamano efe pakeng tsa libere le CNC?

Bearing le CNC machining li hokahane haholo lits'ebetsong tsa sejoale-joale tsa tlhahiso.Mechini ea CNC (Computer Numerical Control) e sebelisoa ho laola le ho iketsetsa mokhoa oa ho sebetsa, ho sebelisoa moralo o thusoang ke khomphutha (CAD) le software ea tlhahiso ea khomphutha (CAM) ho etsa likarolo le lihlahisoa tse nepahetseng haholo.Li-bearings ke karolo ea bohlokoa ea litsamaiso tsa motsamao oa spindle le linear tsa mochini oa CNC, o fanang ka ts'ehetso le ho fokotsa likhohlano lipakeng tsa likarolo tse potolohang.Sena se lumella motsamao o boreleli le o nepahetseng oa sesebelisoa sa ho itšeha kapa sesebediswa sa mosebetsi, se fellang ka ho fokotsa ho nepahetseng le lihlahisoa tse feliloeng tsa boleng bo holimo.

Mechine ea CNC'me theknoloji ea ho jara e ntlafalitse haholo katleho ea tlhahiso le ho nepahala, ho lumella bahlahisi ho hlahisa likarolo tse rarahaneng tse nang le mamello e thata ka lebelo le potlakileng ho feta mekhoa e tloaelehileng ea machining.Ka kakaretso, motsoako oaLikarolo tsa mochini oa CNCle theknoloji ea ho jara e fetotse tlhahiso ea morao-rao le ho nolofalletsa tlhahiso ea likarolo le lihlahisoa tsa boleng bo phahameng ka tekanyo e kholo.

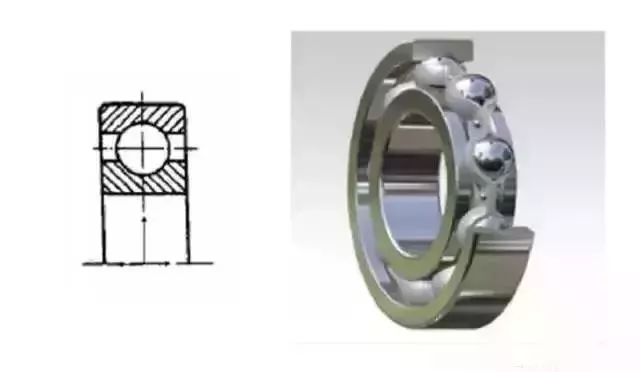

6. Deep groove bolo libering

Ho ea ka sebopeho, selikalikoe se seng le se seng sa "deep groove ball" se na le tsela e tsoelang pele ea mofuta oa groove e nang le karolo ea sefapano e ka bang karolo ea boraro ea sekalikoe sa equatorial sa bolo.Li-deep groove ball bearings li sebelisoa haholo ho jara meroalo ea radial, hape li ka jara meroalo e itseng ea axial.

Ha "radial clearance" ea "bearing" e eketsehang, e na le thepa ea "angular contact ball" mme e ka jara meroalo e fapanyetsanang ea axial ka litsela tse peli.Ha ho bapisoa le mefuta e meng ea li-bearings tse nang le boholo bo lekanang, mofuta ona oa ho jara o na le coefficient e nyenyane ea likhohlano, lebelo le phahameng la moeli, le ho nepahala ho phahameng.Ke mofuta oa ho jara o ratoang bakeng sa basebelisi ha ba khetha mefuta.

Deep Groove Ball Bearings

Lisebelisoa tsa mantlha: likoloi, literekere, lisebelisoa tsa mochini, li-motor, lipompo tsa metsi, mechini ea temo, metjhini ea masela, jj.

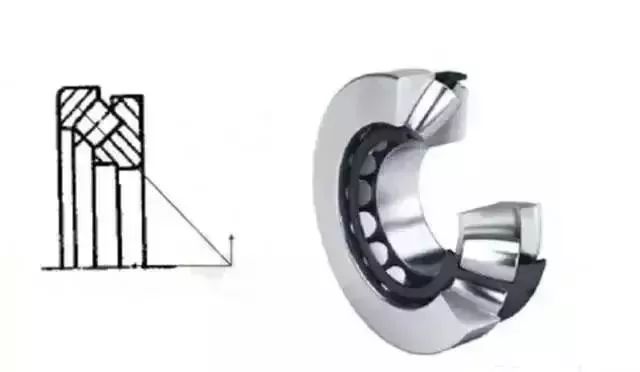

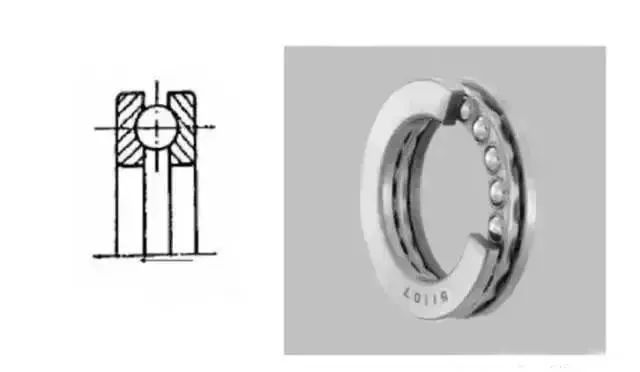

7. Ho phahamisa li-ball bearings

E na le selikalikoe sa peiso sa sebopeho sa washer se nang le tsela ea peiso, bolo le kopano ea cage.Lesale la peiso le tsamaisanang le shaft le bitsoa selikalikoe sa shaft, 'me selikalikoe sa peiso se lumellanang le ntlo se bitsoa lesale la setulo.Li-bearings tse peli li tsamaisana le sekhukhu sa sekhukhu sa selikalikoe se bohareng, li-bearings tsa tsela e le 'ngoe li ka jara meroalo ea axial ka tsela e le' ngoe, 'me li-bearings tse peli li ka jara meroalo ea li-axial tse peli (ha ho le e 'ngoe ea tsona e khonang ho jara meroalo ea mahlaseli).

Ho phahamisa bolo

Sesebelisoa sa mantlha: phini ea ho tsamaisa koloi, spindle ea sesebelisoa sa mochini.

8. Li-bearings tsa rolara

Li-bearings tsa thrust roller li sebelisetsoa ho jara li-axial load-based shafts, moroalo o kopantsoeng oa warp, empa mojaro oa warp ha oa lokela ho feta 55% ea mojaro oa axial.Ha ho bapisoa le li-bearings tse ling tsa thrust roller, mofuta ona o na le coefficient e tlase ea likhohlano, lebelo le holimo le bokhoni ba ho ikamahanya le maemo.Lirolara tsa li-bearings tsa mofuta oa 29000 ke li-roller tse chitja tse asymmetrical, tse ka fokotsang ho thella ho lekanyelitsoeng lipakeng tsa thupa le peiso nakong ea mosebetsi, 'me li-roller li telele, li le bophara bo boholo,' me palo ea lirolara e kholo.Bophahamo ba mojaro bo boholo, 'me hangata ho sebelisoa lubrication ea oli.Lubrication ea mafura e fumaneha ka lebelo le tlase.

Li-Roller Bearings

Sesebelisoa sa mantlha: jenereithara ea motlakase oa metsi, hook ea crane.

9. Cylindrical rolara dibering

Li-roller tsa li-cylindrical roller bearings hangata li tataisoa ke likhopo tse peli tsa selikalikoe sa ho beleha, 'me sekoti sa cage le selikalikoe sa tataiso se etsa kopano e ka arohanngoa le lesale le leng la ho jara, e leng bere e arohaneng.

Mofuta ona oa ho jara o bonolo ho kenya le ho qhaqhoa, haholo-holo ha mehele ea ka hare le ea ka ntle le shaft le matlo li hlokeha ho ba le tšitiso e lekaneng.Li-bearings tse joalo ka kakaretso li sebelisoa feela ho jara meroalo ea radial, 'me li-bearings tsa mela e le 'ngoe feela tse nang le likhopo ka meheleng ea ka hare le ea ka ntle li ka jara meroalo e menyenyane e tsitsitseng ea axial kapa meroalo e meholo e sa khaotseng ea axial.

Cylindrical Roller Bearings

Lisebelisoa tsa mantlha: li-motor tse kholo, li-spindle tsa lisebelisoa tsa mochini, mabokose a li-axle, li-crankshaft tsa enjene ea dizeli, likoloi, li-gearbox, jj.

10. Lintlha tse 'nè tsa li-ball bearings

E ka jara boima ba radial le bi-directional axial load.Bearing e le 'ngoe e ka nka sebaka sa li-angular ball bearings tse kopantsoeng ka pele kapa ka morao.E loketse ho jara mojaro o hloekileng oa axial kapa mojaro oa maiketsetso o nang le karolo e kholo ea axial load.Mofuta ona oa ho jara o ka mamella tataiso leha e le efe E 'ngoe ea li-angles tsa ho kopana li ka thehoa ha mojaro oa axial o sebelisoa, kahoo lesale le bolo li lula li kopana le mahlakoreng a mabeli le lintlha tse tharo holim'a mohala ofe kapa ofe oa ho kopana.

Lintlha tse 'ne tsa li-ball bearings

Lisebelisoa tsa mantlha: li-enjini tsa jete tsa sefofane, li-turbine tsa khase.

11. Hlakola libere tsa rolara tsa cylindrical

E na le mehele ea mabelo a sebopeho sa washer (mehele ea shaft, mehele ea setulo) e nang le lirolara tsa cylindrical le likopano tsa cage.Lirolara tsa li-cylindrical li sebetsoa ka bokaholimo ba li-convex, kahoo kabo ea khatello lipakeng tsa lirolara le sebaka sa mabelo e tšoana, 'me e ka jara meroalo ea axial unidirectional.Matla a axial mojaro a maholo 'me axial rigidity e boetse e matla.

Li-Cylindrical Roller Bearings

Lisebelisoa tsa mantlha: lisebelisoa tsa ho cheka oli, mochini oa tšepe le oa tšepe.

12. Hula li-bearings tsa nale

Li-bearings tse arohaneng li entsoe ka mehele ea mabelo, li-roller tsa linale le likopano tsa cage, tse ka kopanngoang le mehele e tšesaane ea peiso e entsoeng ka mehele kapa mehele e teteaneng e entsoeng ka ho itšeha.Li-bearings tse sa arohaneng ke li-bearings tse kopantsoeng tse entsoeng ka mehele e nepahetseng ea peiso, li-roller tsa linale le likopano tsa cage, tse ka mamellang meroalo e sa tšoaneng ea axial.Mofuta ona oa ho jara o nka sebaka se senyenyane mme o loketse moralo o kopaneng oa mochini.Ho sebelisoa feela rolara ea nale le cage, 'me sebaka se ntseng se phahama sa shaft le matlo se sebelisoa e le sebaka sa peiso.

Li-bearings tsa Nale Roller

Sesebelisoa sa mantlha: Lisebelisoa tsa phetisetso ea likoloi, balemi, lisebelisoa tsa mochini, jj.

13. Hlakola libere tsa rolara tse tapered

Mofuta ona oa ho beleha o na le li-rollers tsa cylindrical tse nang le truncated (qetello e kholo ke sebaka se chitja), 'me li-roller li tataisoa ka nepo ke likhopo tsa lesale la peiso (lesale la shaft, selikalikoe sa setulo).Lithako tsa bokaholimo bo bong le bo bong ba khokahanyo li kopana sebakeng se bohareng ba bethe.Li-bearings tsa tsela e le 'ngoe li ka jara meroalo ea axial ea tsela e le' ngoe, 'me li-axial bearings tse peli li ka jara meroalo ea litsela tse peli.

Li-bearings tsa Thrust Tapered Roller

Sepheo se seholo:

Tsela e le 'ngoe: hook ea crane, rig ea ho cheka oli e swivel.

Karolo e 'meli: molala o bilikang oa leloala.

14. bolo ea ka ntle e chitja e nang le setulo

bolo e kantle e chitja e nang le setulo e entsoe ka bolo e kantle e chitja e nang le litiiso mahlakoreng ka bobeli le setulo sa ho beleha sa samente (kapa setempe).Sebopeho se ka hare sa bolo ea kantle e chitja se tšoana le sa "deep groove ball", empa reng e ka hare ea mofuta ona e pharalletse ho feta selikalikoe sa kantle, 'me selikalikoe sa kantle se na le bokantle ba spherical. ho lokisoa ka tsela e iketsang ha e tsamaellana le sebaka se chitja sa concave sa setulo sa ho jara.

HoCNC e fetoha, li-bearings li phetha karolo ea bohlokoa ho netefatsa ho nepahala le boleng ba likarolo tse felileng.CNC turning ke mokhoa oo sesebelisoa sa ho itšeha se tlosang thepa ho tloha mosebetsing o potolohang ho etsa sebopeho kapa sebopeho se lakatsehang.Li-bearings li sebelisoa litsamaisong tsa li-spindle le linear tsa motsamao oaCNC latheho ts'ehetsa mosebetsi o potolohang le sesebelisoa sa ho itšeha.Ka ho fokotsa likhohlano le ho fana ka ts'ehetso, li-bearings li lumella sesebelisoa sa ho itšeha hore se tsamaee hantle le ka mokhoa o nepahetseng holim'a sebaka sa mosebetsi, ho etsa likhahla tse nepahetseng le tse tšoanang.Sena se fella ka likarolo tse tsitsitseng, tsa boleng bo phahameng tse finyellang litlhaloso tse hlokahalang.

Theknoloji ea ho fetoha ea CNC e fetotse indasteri ea tlhahiso, e etsa hore ho khonehe ho hlahisa likarolo tse rarahaneng tse nang le mamello e thata le katleho e phahameng.

Anebon e fana ka ho tiea ho hoholo ho tsoileng matsoho le tsoelopeleng, thekisong, thekisong e felletseng le papatso le ts'ebetso bakeng sa Moetsi oa OEM/ODM Precision Iron Stainless Steel.Ho tloha ha lefapha la tlhahiso le thehoa, Anebon e se e ikemiseditse tsoelopeleng ea thepa e ncha.Hammoho le lebelo la sechaba le moruo, re tla tsoelapele ho ntšetsa pele moea oa "bokhabane bo holimo, bokhabane, boqapi, bots'epehi", le ho lula le molao-motheo oa ts'ebetso oa "mokoloto qalong, moreki oa pele, boleng bo botle bo holimo".Anebon e tla hlahisa bokamoso bo botle bo bonoang molemong oa tlhahiso ea moriri le bo-mphato ba rona.

Moetsi oa OEM/ODM China Casting le Steel Casting, Moralo, ho sebetsa, ho reka, ho hlahloba, ho boloka, ho bokella, kaofela li ts'ebetsong ea mahlale le e sebetsang ea litokomane, ho eketsa boemo ba ts'ebeliso le ts'epahalo ea mofuta oa rona ka botebo, e leng se etsang hore Anebon e be morekisi ea phahameng oa thepa. mekhahlelo e mene e meholo ea lihlahisoa, joalo ka machining a CNC, likarolo tsa ho sila tsa CNC, ho fetoha ha CNC le li-castings tsa tšepe.

Nako ea poso: Apr-10-2023