1. Umqondo wokuqina kwensimbi ebusweni

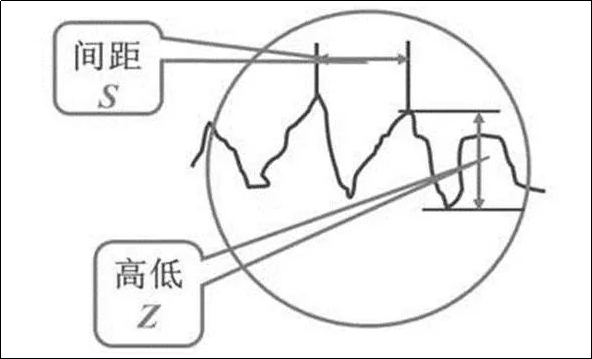

Ubulukhuni bobuso busho ukungalingani kwamabala amancane neziqongo ezincane nezigodi indawo esebenza ngomshini enayo.Ibanga (ibanga lamagagasi) phakathi kweziqongo ezimbili noma imikhombe emibili lincane kakhulu (ngaphansi kuka-1mm), okungelephutha lesimo sejiyomethri encane kakhulu.

Ngokuqondile, kubhekiselwa kuzinga lobude nebanga S leziqongo nezigodi ezincane.Ngokuvamile ihlukaniswa ngu-S:

-

I-S<1mm iwubukhulu obungaphezulu;

- 1≤S≤10mm wukuzamazama;

- S>10mm umumo ka-f.

2. VDI3400, Ra, Rmax ithebula lokuqhathanisa

Izinga likazwelonke libeka ukuthi izinkomba ezintathu ezivame ukusetshenziselwa ukuhlola ubulukhuni bobuso (iyunithi ingu-μm): ukuchezuka kwe-arithmetic okumaphakathi kuka-Ra wephrofayili, ubude obumaphakathi obuyi-Rz bokungalingani kanye nobude obukhulu obungu-Ry.Inkomba ye-Ra ivame ukusetshenziswa ekukhiqizeni kwangempela.Ubukhulu bokuchezuka kobude obuncane be-Ry bephrofayili kuvame ukuvezwa uphawu lwe-Rmax e-Japan nakwamanye amazwe, futhi inkomba ye-VDI isetshenziswa kakhulu e-Europe nase-United States.Ngezansi kunethebula lokuqhathanisa le-VDI3400, Ra, Rmax.

I-VDI3400, i-Ra, ithebula lokuqhathanisa le-Rmax

| | | |

| | | |

| | | |

| | | |

| | | |

| | | |

| | | |

| | | |

| | | |

| | | |

| | | |

| | | |

3. Izinto ezakha ubuhwaqane bobuso

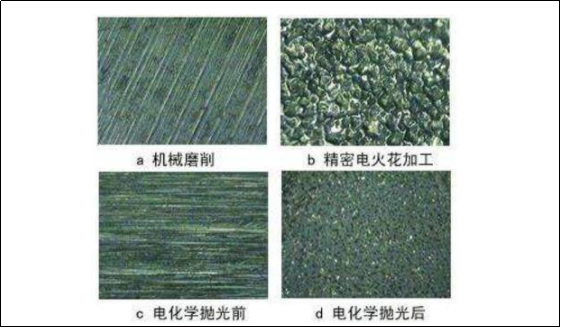

Ubulukhuni bobuso ngokuvamile bakheka indlela yokucubungula esetshenziswayo nezinye izici, njengokungqubuzana phakathi kwethuluzi nobuso bensimbi.cnc machining ingxenyengesikhathi sokucutshungulwa, ukuguqulwa kwepulasitiki kwensimbi yongqimba olungaphezulu lapho i-chip ihlukaniswa, kanye nokudlidliza kwemvamisa ephezulu ohlelweni lwenqubo, imigodi yokukhipha imishini kagesi, njll. Ngenxa yezindlela ezihlukene zokucubungula nezinto zokusebenza, ukujula, ukuminyana, ukuma. kanye nokuthungwa kweminonjana esele endaweni ecutshunguliwe kuhlukile.

4. Ukubonakaliswa okuyinhloko komthelela wobunzima obungaphezulu ezingxenyeni

I-1) Kuthinta ukumelana nokugqoka.Lapho ingaphezulu liqinile, incane indawo yokuxhumana ephumelelayo phakathi kwezindawo zokukhwelana, ingcindezi inkulu, ukumelana nokungqubuzana okukhulu, kanye nokuguga ngokushesha.

2) Kuthinta ukuzinza kokulingana.Ukuze uthole imvume yokungena, i-rougher surface, kulula ukugqoka, ukuze igebe likhule kancane kancane phakathi nenqubo yokusebenza;amandla okuxhumana.

3) Ukuthinta amandla okukhathala.Kukhona imisele emikhulu ebusweni bezingxenye ezimahhadlahhadla, ezizwelayo ekugxilweni kwengcindezi njengamanotshi abukhali nemifantu, ngaleyo ndlela kuthinte amandla okukhathalaukunemba izingxenye.

I-4) Ithinta ukumelana nokugqwala.Izingxenye eziqinile ezingaphezulu zingabangela kalula igesi ebolayo noma uketshezi ukuthi lungene engxenyeni engaphakathi yensimbi ngokusebenzisa izigodi ezincane ezingaphezulu, okubangele ukugqwala kwendawo.

5) Kuthinta ukuqina.Izindawo ezimahhadlahhadla azikwazi ukuhlangana ziqine, futhi igesi noma uketshezi luvuza ngezikhala phakathi kwezindawo zokuthintana.

I-6) Ithinta ukuqina kokuxhumana.Ukuqina kokuxhumana yikhono lendawo ehlangene yezingxenye ukumelana ne-deformation ngaphansi kwesenzo samandla angaphandle.Ukuqina komshini kunqunywa kakhulu ukuqina kokuxhumana phakathi kweizingxenye ze-cnc lathe.

7) Kuthinta ukunemba kwesilinganiso.Ubulukhuni obungaphezulu bobuso obulinganisiwe bengxenye kanye nendawo yokulinganisa yethuluzi lokulinganisa kuzothinta ngokuqondile ukunemba kwesilinganiso, ikakhulukazi esilinganisweni esinembile.

Ukwengeza, ubulukhuni bendawo buzoba namazinga ahlukahlukene ethonya ekuhlanganisweni kwe-plating, ukuqhutshwa kwe-thermal kanye nokumelana nokuxhumana, ukubonakaliswa nokusebenza kwemisebe yezingxenye, ukumelana nokugeleza koketshezi negesi, nokugeleza kwamanje ebusweni bamakhondatha.

5. isisekelo sokuhlola ubuhwaqane bobuso

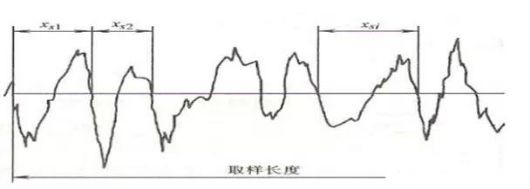

1. Ubude besampula

Ubude besampula ubude bomugqa wereferensi obalulwe ekuhlolweni kokuqina kwendawo.Ngokokwakheka nezici zokuthungwa kwendawo yangempela yengxenye, ubude obungabonisa izici zokuhwaya kwendawo kufanele kukhethwe, futhi ubude besampula kufanele bulinganiswe ngokuvumelana nethrendi evamile yekhonta yangempela yendawo.Inhloso yokucacisa nokukhetha ubude besampula ukukhawulela nokwenza buthaka umthelela wokuguquguquka kwendawo kanye namaphutha omumo emiphumeleni yokulinganisa yobulukhuni bendawo.

2. Ubude bokulinganisa

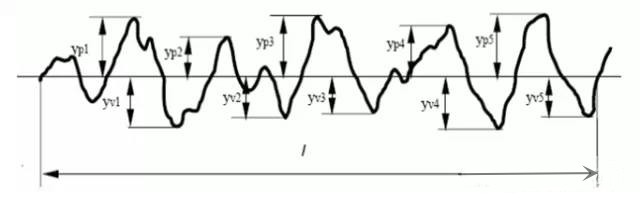

Ubude bokuhlola ubude obudingekayo ukuze kuhlolwe iphrofayela, futhi bungabandakanya ubude besampula obubodwa noma ambalwa.Njengoba ubulukhuni bengxenye yengxenye ngayinye yobuso bengxenye abufani ngempela, isici esithile sokuhwashazela kwangaphezulu asikwazi ukuboniswa ngokunengqondo kubude besampula obubodwa, ngakho-ke kuyadingeka ukuthatha ubude besampula obuningana phezulu ukuze kuhlolwe ubulukhuni obungaphezulu.Ubude bokuhlola ngokuvamile buhlanganisa ubude besampula obungu-5.

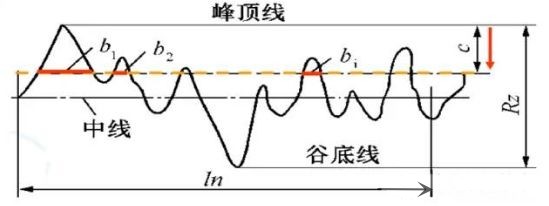

3. Isisekelo

Ulayini wereferensi uwumugqa omaphakathi wephrofayela esetshenziselwa ukuhlola amapharamitha wokuma okungaphezulu.Kunezinhlobo ezimbili zemigqa yereferensi: umugqa omncane oyisikwele we-median wekhontayutha: ngaphakathi kobude besampula, isamba sezikwele ze-contour offset amabanga ephuzu ngalinye emgqeni wekhonta yincane kunawo wonke, futhi inomumo wekhonta wejiyomethri. .I-arithmetic isho umugqa omaphakathi wekhontayutha: ngaphakathi kobude besampula, izindawo zamakhonco ngenhla nangaphansi komugqa omaphakathi ziyalingana.Ngokwethiyori, ulayini we-midian onezikwele ezincane uyisisekelo esikahle, kodwa kunzima ukutholakala ezinsizeni ezingokoqobo, ngakho-ke ngokuvamile uthathelwa indawo umugqa we-arithmetic mean median wekhonta, futhi umugqa oqondile onendawo cishe ungasetshenziswa yishintshe ngesikhathi sokulinganisa.

6. Amapharamitha okuhlola ukuhwalala kobuso

1. Ukuphakama isici nemingcele

Incazelo yezibalo zephrofayili ye-Ra: incazelo ye-arithmetic yenani eliphelele lokuchezuka kwephrofayela ngaphakathi kobude besampula (lr).Esilinganisweni sangempela, lapho inani lamaphuzu okulinganisa liba likhulu, i-Ra inembe kakhulu.

Ubude bephrofayili ye-Rz: ibanga phakathi komugqa ophakeme wephrofayili kanye nomugqa ongezansi wesigodi.

I-Ra ikhethwa kububanzi obujwayelekile bemingcele ye-amplitude.Esilinganisweni sikazwelonke ngaphambi kuka-2006, kwakukhona enye ipharamitha yokuhlola "eyayingubude obunamaphoyinti ayishumi we-micro-roughness" evezwe yi-Rz, futhi ukuphakama okuphezulu kwekhonsathi kuvezwe ngu-Ry.Ngemuva kuka-2006, izinga likazwelonke lakhansela ukuphakama kwamaphoyinti ayishumi we-micro-roughness, kwasetshenziswa i-Rz.Ibonisa ukuphakama okuphezulu kwephrofayela.

2. Amapharamitha wesici sesikhala

RsmIsilinganiso sobubanzi bezinto zekhonta.Ngaphakathi kobude besampula, inani elimaphakathi lebanga eliphakathi kokungahambi kahle kwe-microscopic yephrofayela.Isikhala sobukhulu obuncane sisho ubude bebanga lephrofayela kanye nesigodi sephrofayela esiseduze emugqeni omaphakathi.Esimeni senani lika-Ra elifanayo, inani le-Rsm alifani ngempela, ngakho ukuthungwa okubonisiwe kuzohluka.Ubuso obunaka ukuthungwa ngokuvamile bunaka izinkomba ezimbili ze-Ra ne-Rsm.

IRmripharamitha yesici somumo imelelwa isilinganiso sobude bokusekela ikhonta, okuyisilinganiso sobude bokusekela kwekhonta kuya kubude besampula.Ubude bokusekela iphrofayela yisamba sobude bemigqa yesigaba etholwe ngokuphambana nephrofayili ngomugqa oqondile ohambisana nomugqa omaphakathi kanye nebanga elingu-c ukusuka emugqeni wesiqongo sephrofayela ngaphakathi kobude besampula.

7. Indlela yokulinganisa ubuheshe bobuso

1. Indlela yokuqhathanisa

Isetshenziselwa ukulinganisa endaweni endaweni yokusebenzela, futhi ivame ukusetshenziselwa ukukala indawo ephakathi nendawo noma emangelengele.Indlela iwukuqhathanisa indawo elinganiselwe nesampula yokumakwa kwenani elithile ukuze kutholwe inani lobuhwaqane obulinganisiwe.

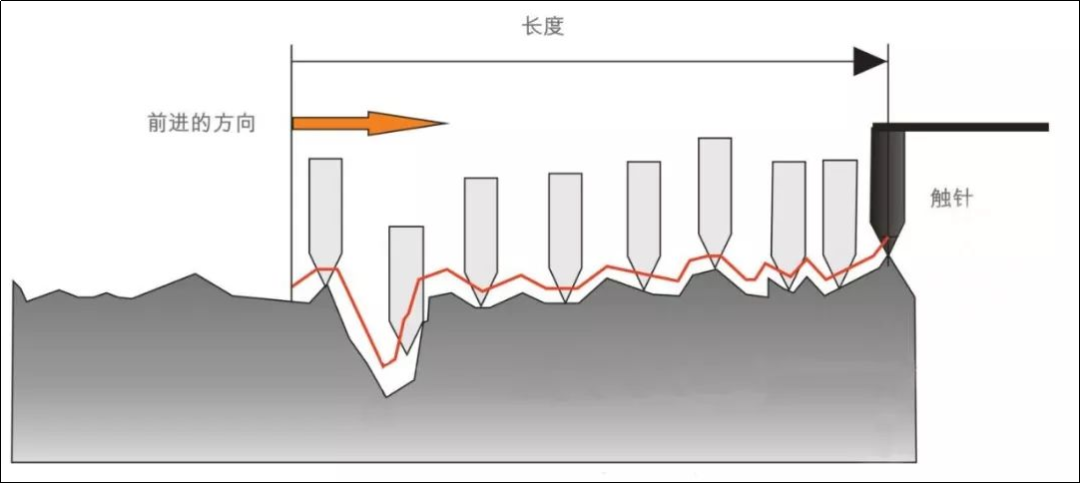

2. Indlela ye-Stylus

Ubulukhuni obungaphezulu busebenzisa i-stylus yedayimane enerediyasi yethiphu yokugoba cishe ama-microns angu-2 ukuze islayidi kancane endaweni elinganiselwe.Ukugudluzwa phezulu naphansi kokuloba kwedayimane kuguqulwa kube isignali kagesi ngenzwa yobude kagesi, futhi kuboniswa ithuluzi lokubonisa ngemva kokukhulisa, ukuhlunga, nokubala.Ivelu yokuqina kwendawo ingatholakala, futhi irekhoda ingasetshenziswa futhi ukurekhoda ijika lephrofayela yesigaba esilinganisiwe.Ngokuvamile, ithuluzi lokulinganisa elingabonisa kuphela inani lobunzima obungaphezulu libizwa ngokuthi ithuluzi lokulinganisa ubushelelezi obungaphezulu, futhi leli elingarekhoda ijika lephrofayili engaphezulu libizwa ngokuthi iphrofayili yokuqina kwendawo.Lawa mathuluzi wokulinganisa amabili anesekhethi yokubala ye-elekthronikhi noma amakhompyutha e-elekthronikhi, akwazi ukubala ngokuzenzakalelayo ukuchezuka kwencazelo ye-arithmetic u-Ra wekhonta, ukuphakama kwamaphoyinti ayishumi u-Rz wokungalingani kwe-microscopic, ukuphakama okuphezulu kwe-Ry yekhonta kanye namanye amapharamitha okuhlola, aphezulu ukusebenza kahle kokulinganisa futhi kulungele Ukuqineka kwendawo ye-Ra ngama-microns angu-0.025-6.3 kuyalinganiswa.

Okuphishekela ingunaphakade kwe-Anebon yisimo sengqondo “sokubheka imakethe, bheka inkambiso, bheka isayensi” kanye nethiyori “yekhwalithi eyisisekelo, themba owokuqala nokuphatha okuthuthukile” kwe-Hot sale Factory OEM Service High Precision CNC Machining izingxenye zokuzenzakalela. yezimboni, i-Anebon quote yombuzo wakho.Ukuze uthole ulwazi olwengeziwe, sicela uxhumane nathi, i-Anebon izokuphendula ASAP!

I-Hot sale Factory China 5 axis cnc machining parts, i-CNC yaphenduka izingxenye kanyeingxenye yethusi yokugaya.Siyakwamukela ukuvakashela inkampani yethu, ifekthri kanye negumbi lethu lokubonisa lapho libonisa khona ukuthengiswa kwezinwele okuhlukahlukene okuzohlangabezana nokulindela kwakho.Okwamanje, kulula ukuvakashela iwebhusayithi ye-Anebon, futhi abasebenzi bezokuthengisa be-Anebon bazozama konke okusemandleni abo ukukuletha isevisi engcono kakhulu.Sicela uxhumane ne-Anebon uma kufanele ube nolwazi oluthe xaxa.Inhloso ye-Anebon ukusiza amakhasimende abone izinhloso zawo.I-Anebon ibilokhu yenza imizamo emikhulu yokufeza lesi simo sokunqoba.

Isikhathi sokuthumela: Mar-25-2023