Isevisi ye-Die Casting

I-Die casting bekuyisipesheli se-Anebon iminyaka engaphezu kwe-10.Izinsizakalo zethu zokulingisa i-aluminium bezisiza onjiniyela, abaklami bemikhiqizo nabadwebi bezakhiwo ukuba benze imiklamo yabo iphile ngemiklamo yengxenye yobuciko nekhwalithi ethembekile.Uma kubhekwa ulwazi lwethu embonini, kanye nezisetshenziswa zethu zesimanjemanje, onjiniyela bethu abangochwepheshe bokukhiqiza kanye nekhwalithi, kanye nabasebenzi bokukhiqiza, uqinisekisiwe ukukhiqizwa kwekhwalithi yezingxenye zakho nemikhiqizo ngenani elingokomnotho nge-Anebon.Singabakhi be-ISO 9001:2015 abafaka ukufa okuqinisekisiwe abasebenza ngokukhethekile ekulingiseni izimboni nezinkampani ezihamba phambili emhlabeni.Imishini yethu ihlanganisa cishe zonke izidingo zobunjiniyela, ukuklama kanye nentuthuko inkampani yakho engase idinge.

Imishini yokuphonsa kanye nesikhunta kuyabiza, ngakho-ke inqubo ye-die casting ngokuvamile isetshenziselwa ukukhiqiza inani elikhulu lemikhiqizo.Kulula kakhulu ukwenza izingxenye ze-die-cast, ngokuvamile ezidinga izinyathelo ezine ezinkulu kuphela, kanti ukukhuphuka kwezindleko okukodwa kube kuphansi.I-Die casting ifaneleka ngokukhethekile ukukhiqizwa kwenani elikhulu lama-castings amancane naphakathi nendawo, ngakho-ke i-die casting isetshenziswa kakhulu ezinqubweni zokuphonsa ezihlukahlukene.Uma kuqhathaniswa namanye amasu okulingisa, i-die-cast surface ithambile futhi inokungaguquguquki okuphezulu okuphezulu.

Yini i-Die Casting?

I-Die casting iyinqubo yokuphonsa kwensimbi ebonakala ngokusetshenziswa kwesikhunta ukuze kufakwe ukucindezela okukhulu ensimbi encibilikisiwe.Isikhunta sivamise umshini kusuka kuma-alloys anamandla aphezulu, amanye afana nokubunjwa komjovo.Ama-die castings amaningi awanayo i-iron, njenge-zinc, ithusi, i-aluminium, i-magnesium, i-lead, i-tin, nama-alloys e-lead-tin namanye ama-alloys.Ngokuya ngohlobo lwe-die casting, umshini wokuphonsa we-cold chamber noma umshini wokuphonsa wokufa wegumbi elishisayo uyadingeka.

Izici

I-Die casting iyindlela yokuphonsa lapho uketshezi lwe-alloy oluncibilikisiwe luthululelwa ekamelweni lokucindezela, umgodi wesikhunta sensimbi ugcwaliswa ngesivinini esikhulu, futhi uketshezi lwe-alloy luqiniswa ngaphansi kwengcindezi ukuze kwakheka ukubunjwa.Izici eziyinhloko ze-die casting eziyihlukanisa kwezinye izindlela zokusakaza ukucindezela okuphezulu kanye nesivinini esikhulu.

1. Insimbi encibilikisiwe igcwalisa imbobo ngaphansi kwengcindezi bese icwebezela ngomfutho ophakeme.Ingcindezi evamile yi-15-100 MPa.

2 .Uketshezi lwensimbi lugcwalisa umgodi ngesivinini esikhulu, imvamisa ku-10-50 m / s, kanti amanye angadlula ama-80 m / s, (isivinini somugqa singene emgodini - isivinini sokuqoqa), ngakho-ke isikhathi sokugcwalisa insimbi encibilikisiwe sikhulu kakhulu. mfushane, futhi i-cavity ingagcwaliswa cishe imizuzwana engu-0.01-0.2 (kuye ngokuthi ubukhulu bokubunjwa).

I-Die-casting iyindlela yokusakaza enembayo.Izingxenye ze-die-casting ezisakazwa i-die-casting, zinokubekezelela okuncane kakhulu kobukhulu kanye nokunemba okuphezulu kwendawo.Ezimweni eziningi, izingxenye ze-die-casting zingahlanganiswa ngaphandle kokuphenduka.Izingxenye zingaphonswa ngokuqondile.

Yiziphi izinzuzo zezinsizakalo zokulingisa ukufa?

Inqubo yethu yokuguqula ukufa inikezela ngezinzuzo eziningi ezibalulekile, okuhlanganisa:

l Ukwenza ngokwezifiso: Kuyasiza ukufeza imiklamo eyinkimbinkimbi namafomu akwenza kube lula ukwenza ngokwezifiso ukusakazwa kwezinqubo ezithile zokukhiqiza.

ll Izindleko eziphansi

l Ukusebenza okuphezulu

llll Isebenza Kaningi futhi imelana nokugqwala

Njengomkhiqizi we-die-casting, i-Anebon Die Casting inikeza ukuhlangana okuphelele, okuphelele nokuhlolwa kwazo zonke izingxenye ze-die-cast nemikhiqizo.Kungakhathaliseki ukuthi unentshisekelo ezingxenyeni ezikhethekile ezifana ne-aluminium die casting noma i-vacuum die cast, noma ufuna nje ukuba umfanekiso wengxenye entsha, ungathola ulwazi olugcwele lwesevisi efekthri yethu.

Mi-aterial

Insimbi esasiyisebenzisela ukukhishwa kwensimbi ngokuyinhloko ihlanganisa i-zinc, ithusi, i-aluminium, i-magnesium, i-lead, ithini, nama-alloys e-lead-tin, njll. Nakuba insimbi ewuketshezi ingavamile, ingenzeka futhi.Izici zezinsimbi ezihlukahlukene ngesikhathi sokufa zimi kanje:

•Zinc: Insimbi eyi-die-cast elula kakhulu, eyongayo lapho ikhiqiza izingxenye ezincane, ukugqokwa kalula, amandla acindezelayo aphezulu, ipulasitiki ephezulu, nempilo ende yokulingisa.

•I-Aluminium: Ikhwalithi ephezulu, ukukhiqizwa okuyinkimbinkimbi kanye nokusakazwa kwezindonga ezincane ezinokuqina okuphezulu kwe-dimensional, ukumelana nokugqwala okuphezulu, izakhiwo ezinhle zemishini, ukuqhutshwa kwe-thermal okuphezulu kanye nokuhamba kukagesi, namandla aphezulu emazingeni okushisa aphezulu.

•Magnesium: Kulula ukwenza umshini, isilinganiso samandla aphezulu esisindweni, ukukhanya kwezinsimbi ezisetshenziswa kakhulu ezisetshenziswa kakhulu.

•Ithusi: Ukuqina okuphezulu nokumelana nokugqwala okuqinile.Insimbi esetshenziswa kakhulu i-die-cast inezakhiwo ezingcono kakhulu zemishini, i-anti-wear namandla eduze kwensimbi.

•Umthofu kanye nethini: Ukuminyana okuphezulu nokunemba okuphezulu kobukhulu bezingxenye ezikhethekile zokuvikela ukugqwala.Ngenxa yezizathu zempilo yomphakathi, le ngxubevange ayikwazi ukusetshenziswa njengendawo yokucubungula nokugcina ukudla.Ama-alloys e-lead-tin-bismuth (ngezinye izikhathi nawo aqukethe ithusi elincane) angasetshenziswa ukwenza ukubhala ngesandla nokugxiviza okushisayo ekuphrinteni kwe-letterpress.

Aluminium Casting

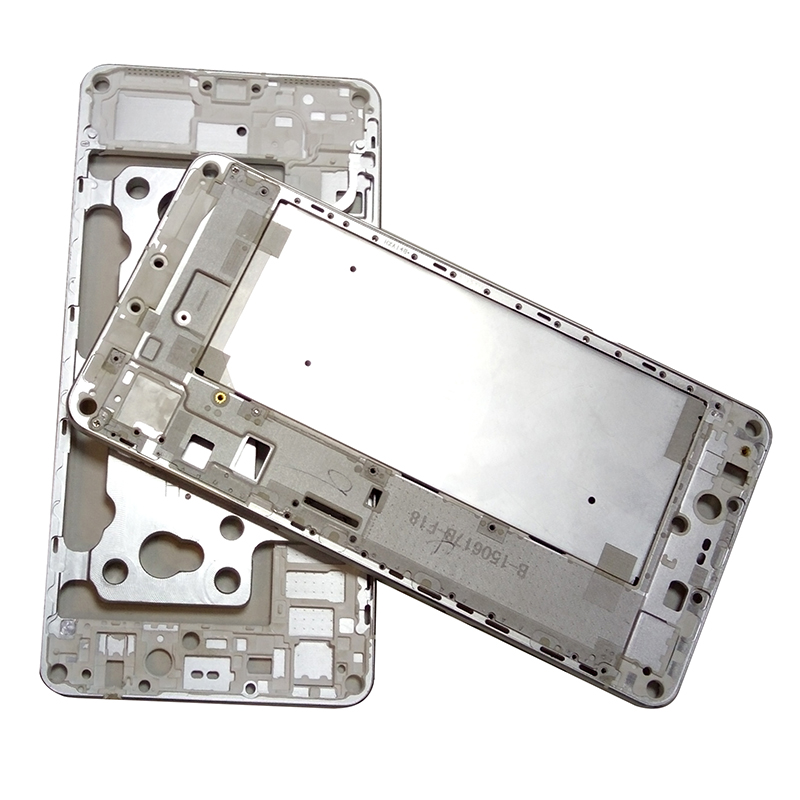

Isakaza Izesekeli Zefoni Ephathwayo

I-Aluminium Die Cast