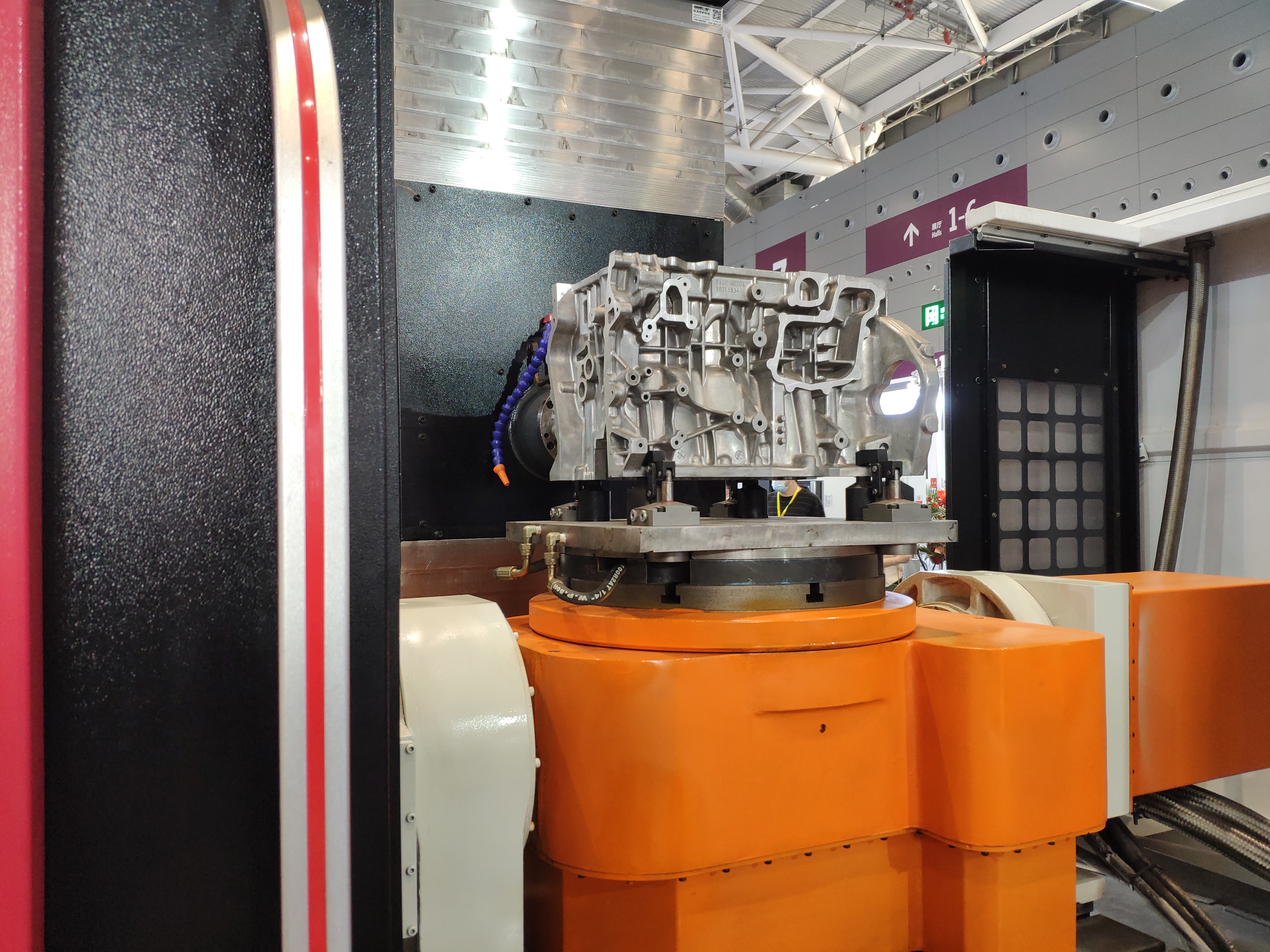

The karfe zafi magani ne don zafi da karfe ko gami workpiece zuwa dace zafin jiki a cikin wani matsakaici, da kuma bayan rike da yawan zafin jiki na wani lokaci, shi ne sanyaya a cikin daban-daban kafofin watsa labarai a daban-daban gudu, ta hanyar canza surface ko ciki na da karfe abu.Tsarin tsari na ƙananan ƙwayoyin cuta don sarrafa aikin sa.cnc machining part

Babban rukuni

Ƙarfe kula da zafin jiki za a iya kusan kashi uku Categories: gaba ɗaya magani zafi, saman zafi magani da kuma sinadaran zafi magani.Dangane da matsakaicin dumama, zafin dumama da hanyar sanyaya, kowane nau'i za a iya raba shi zuwa matakai daban-daban na maganin zafi.Irin wannan ƙarfe yana amfani da matakai daban-daban na maganin zafi don samun nau'o'in microstructures daban-daban kuma don haka kaddarorin daban-daban.Karfe shi ne karfen da aka fi amfani da shi a masana’antar, kuma karamin tsarin karfe shi ma ya fi hadaddun, don haka akwai nau’o’in hanyoyin magance zafi na karfe.Brass cnc machining part

Halaye

Maganin zafi na ƙarfe yana ɗaya daga cikin mahimman matakai a cikin masana'antar injiniya.Idan aka kwatanta da sauran hanyoyin sarrafawa, maganin zafi gabaɗaya baya canza sifa da tsarin sinadarai gabaɗaya na aikin aikin, amma yana canza microstructure a cikin kayan aikin ko canza abubuwan sinadaran saman aikin., don bayarwa ko inganta aikin aikin aikin.Yana da alaƙa da ingantattun ingantattun kayan aikin, wanda gabaɗaya ba a iya gani ga ido tsirara.Sabili da haka, tsari ne na musamman a cikin masana'anta na injiniya da kuma muhimmin sashi na gudanarwa mai inganci.

Domin yin karfe workpiece da ake bukata inji Properties, jiki Properties da sinadaran Properties, ban da m selection na kayan da daban-daban kafa matakai, zafi magani matakai ne sau da yawa da muhimmanci.Karfe shine kayan da aka fi amfani dashi a cikin masana'antar injuna.Microstructure na karfe yana da rikitarwa kuma ana iya sarrafa shi ta hanyar maganin zafi.Sabili da haka, maganin zafi na karfe shine babban abun ciki na maganin zafi na karfe.Bugu da ƙari, aluminum, jan karfe, magnesium, titanium, da makamantansu kuma ana iya canza su ta hanyar maganin zafi don samun kayan aikin injiniya daban-daban, kaddarorin jiki, da sinadarai.

Tsarin asali

Jiyya na zafi gabaɗaya shine tsarin kula da zafi na ƙarfe wanda ke dumama aikin gabaɗaya sannan kuma sanyaya shi cikin saurin da ya dace don canza kaddarorin injin sa gabaɗaya.Gabaɗayan maganin zafi na ƙarfe yana da matakai na asali guda huɗu: annealing, normalizing, quenching da tempering.bangaren filastik

Annealing shine don dumama kayan aikin zuwa yanayin da ya dace, ta amfani da lokutan riƙewa daban-daban bisa ga kayan da girman kayan aikin, sannan a sanyaya a hankali, don kawo tsarin ciki na ƙarfe zuwa ko kusa da daidaito, ko don sakin damuwa na ciki da aka haifar ta hanyar da ta gabata.Samun kyakkyawan tsari da aiki, ko shirya don ƙarin quenching.

Daidaita ko daidaitawa shine sanyaya kayan aikin zuwa yanayin da ya dace sannan sanyaya shi cikin iska.Sakamakon al'ada yana kama da annealing, amma tsarin da aka samo shi ya fi kyau, wanda ake amfani dashi sau da yawa don inganta aikin yanke kayan aiki, kuma wani lokaci ana amfani dashi don wasu buƙatu.Ana amfani da sassan da ba su da girma a matsayin maganin zafi na ƙarshe.

Quenching shine a hanzarta kwantar da kayan aikin bayan dumama da riƙe shi a cikin matsakaiciyar kashewa kamar ruwa, mai ko sauran maganin gishirin inorganic ko maganin ruwa.Bayan quenching, karfe ya zama mai wuya amma ya zama mai karye a lokaci guda.

Domin rage guguwar karfe, karfen da aka kashe yana dadewa a cikin yanayin da ya dace sama da zafin dakin da kasa da 650 ° C, sannan a sanyaya.Ana kiran wannan tsari tempering.Ragewa, daidaitawa, quenching da zafin rai sune "wuta hudu" a cikin maganin zafi gabaɗaya.Daga cikin su, quenching da tempering suna da alaƙa da alaƙa, kuma sau da yawa ana amfani da su tare, ba makawa.

Anebon Metal Products Limited na iya samar da CNC Machining, Die Casting, Sheet Metal Fabrication sabis, da fatan za a iya tuntuɓar mu.

Tel: +86-769-89802722 E-mail: info@anebon.com URL: www.anebon.com

Lokacin aikawa: Agusta-31-2019