News

-

A small tap can contain so much information. . .

Tap chippingTapping is a relatively difficult machining process, because its cutting edge is basically in 100% contact with the workpiece, so various problems that may arise should be considered in advance, such as the performance of the workpiece, the selection of tools and machine tools, and t...Read more -

Another “lighthouse factory” in China! ! !

In 2021, the World Economic Forum (WEF) officially released a new list of “lighthouse factories” in the global manufacturing sector. Sany Heavy Industry’s Beijing pile machine factory was successfully selected, becoming the first certified “lighthouse factory” in the...Read more -

Precautions when the machine tool is shut down for a long time

Good maintenance can keep the machining accuracy of the machine tool in the best state, prolong the service life, and adopt the correct startup and debugging method for the CNC machine tool. In the face of new challenges, it can show a good working state, improve production efficiency and process...Read more -

We are welcoming the Chinese Spring Festival!

We are welcoming the Chinese Spring Festival! The Spring Festival has a long history and evolved from the prayers for the first year of the year in ancient times. All things originate from the sky, and humans originate from their ancestors. To pray for the new year to offer sacrifices, to respect...Read more -

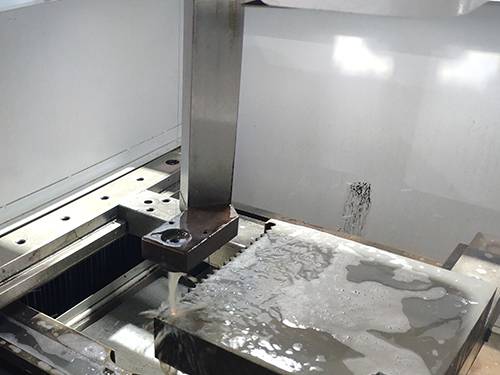

Why is titanium alloy a difficult material to machine?

1. Physical phenomena of titanium machining The cutting force of titanium alloy processing is only slightly higher than that of steel with the same hardness, but the physical phenomenon of processing titanium alloy is much more complicated than that of processing steel, which makes titanium allo...Read more -

Nine major errors in machining, how many do you know?

Machining error refers to the degree of deviation between the actual geometric parameters (geometric size, geometric shape and mutual position) of the part after machining and the ideal geometric parameters. The degree of agreement between the actual geometric parameters and the ideal geomet...Read more -

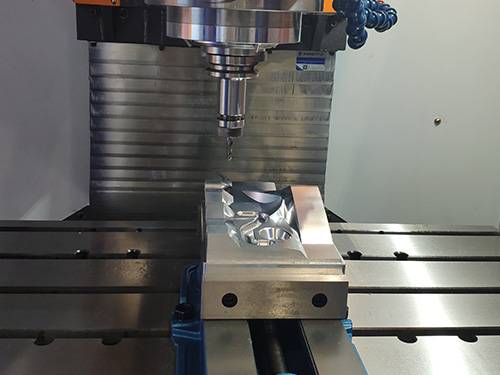

Characteristics of CNC Hard track

Most factories understand hard rails and linear rails: if they are used to make products, they buy linear rails; if they are processing molds, they buy hard rails. The accuracy of the linear rails is higher than that of the hard rails, but the hard rails are more durable. Hard track characteristi...Read more -

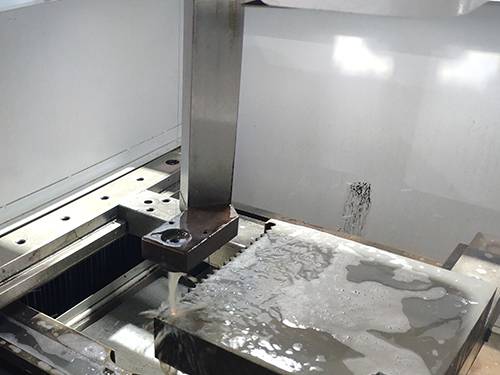

Wire cutting CAXA software drawing programming

Not only high-end machine tools, in fact, the design software is also a foreign brand CAD software that has been monopolizing the domestic market. As early as 1993, China had more than 300 scientific research teams developing CAD software, and CAXA was one of them. When domestic counterparts chos...Read more -

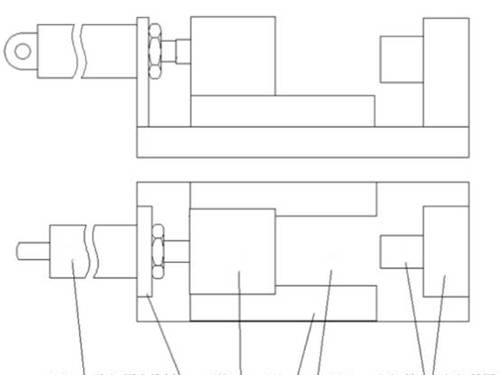

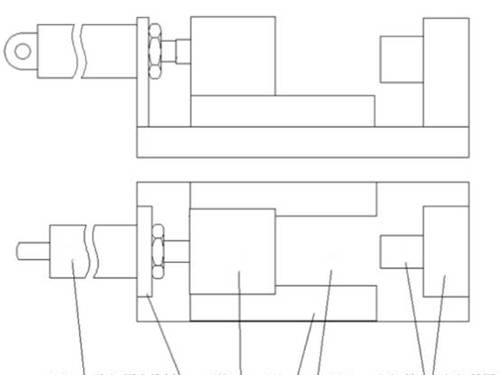

These Design Introductions of Fixtures

The fixture design is generally carried out in accordance with the specific requirements of a certain process after the machining process of the parts is formulated. In formulating the technological process, the possibility of fixture realization should be fully considered, and when designing the...Read more -

How To Distinguish Quenching, Tempering, Normalizing, Annealing

What is quenching? The quenching of steel is to heat the steel to a temperature above the critical temperature Ac3 (hypoeutectoid steel) or Ac1 (hypereutectoid steel), hold it for a period of time to make it fully or partially austenitized, and then cool the steel at a rate greater than the criti...Read more -

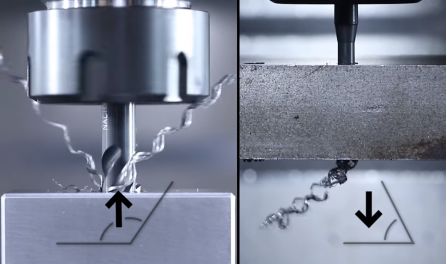

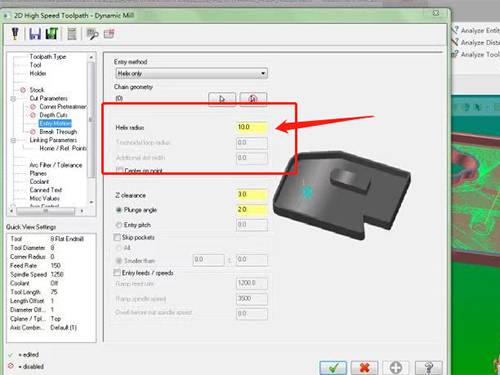

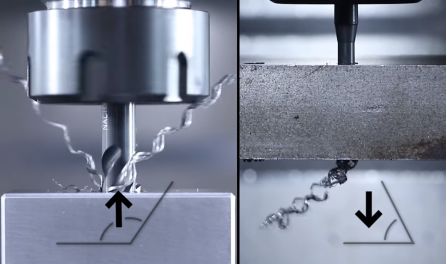

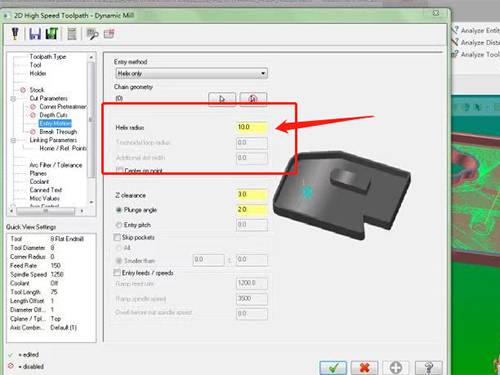

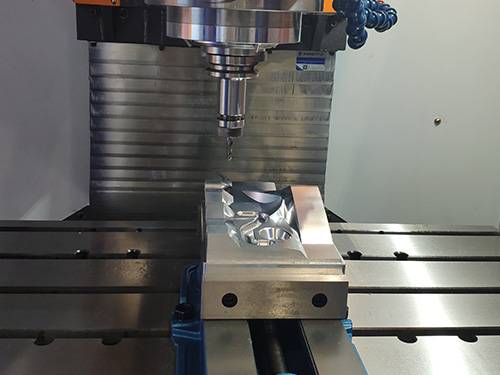

CNC spiral cutting parameter setting

The purpose of all CAM software parameters is the same, which is to prevent “top knife” during CNC machining custom metal service. Because for the tool loaded with the disposable toolholder (it can also be simply understood that the tool blade is not centered), the tool center is not ...Read more -

CNC Curved Products

1 Learning method of surface modeling Facing the many surface modeling functions provided by CAD/CAM software, it is very necessary to master the correct learning method in order to achieve the goal of learning practical modeling in a relatively short time. If you want to master practical modeli...Read more