News

-

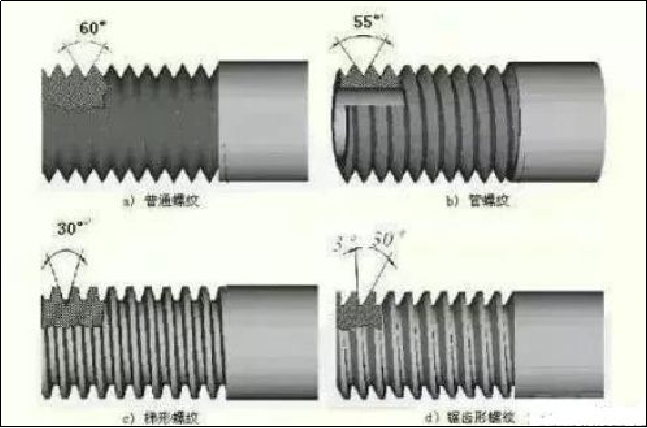

Coarse and fine thread, how to choose?

How fine is the thread that can be called a fine thread? We might as well define it in this way. The so-called coarse thread can be defined as a standard thread; while the fine thread is relative to the coarse thread. Under the same nominal diameter, the number of threads per inch is different, t...Read more -

Basic common sense of machining, don’t do it if you don’t understand it!

1. BenchmarkParts are composed of several surfaces, and each surface has certain size and mutual position requirements. The relative position requirements between the surfaces of the parts include two aspects: the distance dimensional accuracy between the surfaces and the relative position a...Read more -

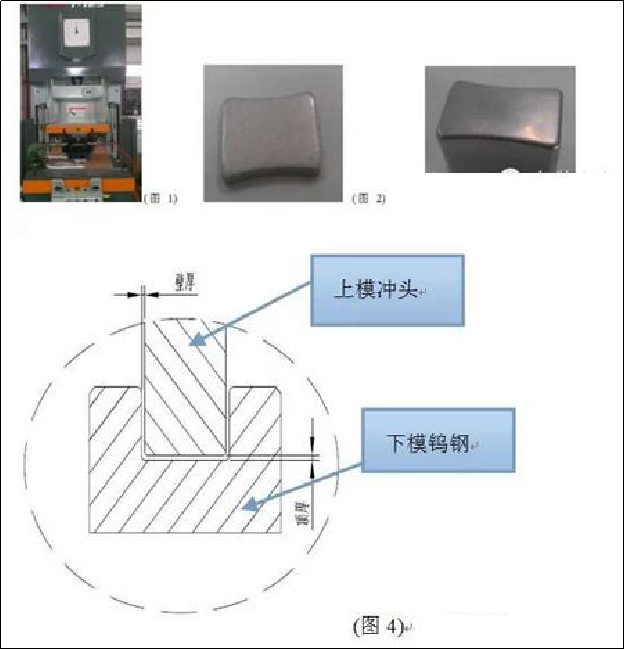

Aluminum product processing technology

Aluminum is the most widely used and widely used metal material in non-ferrous metals, and its application range is still expanding. There are more than 700,000 kinds of aluminum products produced by using aluminum materials. According to statistics, there are more than 700,000 kinds of aluminum ...Read more -

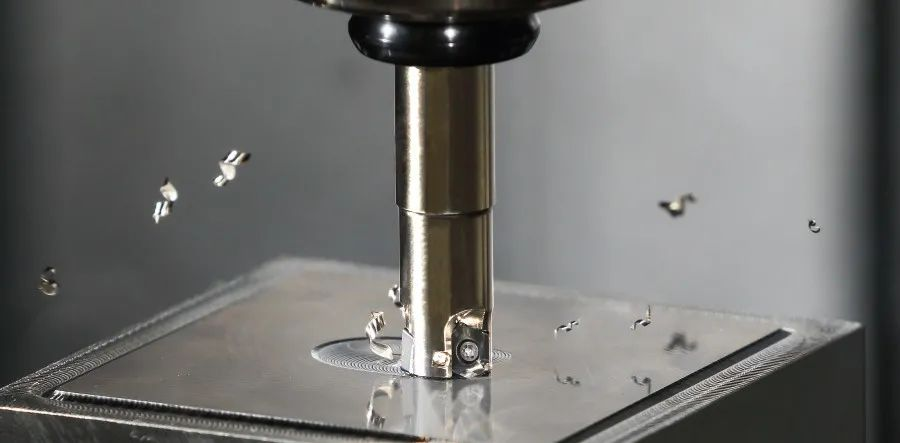

Common problems and solutions of tools in deep hole machining

In the process of deep hole machining, problems such as dimensional accuracy, surface quality and tool life of the workpiece often occur. How to reduce or even avoid these problems is an urgent problem to be solved.1. There are problems: the aperture increases, and the error is large1) CauseThe d...Read more -

Why does stainless steel also rust? Finally figured it out!

Why does stainless steel also rust? When brown rust spots (spots) appear on the surface of stainless steel pipes, people are amazed: “Stainless steel does not rust, and if it rusts, it is not stainless steel, and there may be a problem with the steel.” In fact, this is a one-side...Read more -

The machine has been working for a lifetime, what does the 4.4 and 8.8 on the bolt mean?

After working as a machine for so many years, you must not know the meaning of the labels on the screws, right? The performance grades of bolts for steel structure connection are divided into more than 10 grades such as 3.6, 4.6, 4.8, 5.6, 6.8, 8.8, 9.8, 10.9, 12.9, etc. Among them, the bolts of ...Read more -

Machining cutting fluid can not be ignored!

As we all know, the product qualification rate is a key indicator that machining enterprises pay attention to, and it is also one of the factors that affect the development of enterprises. The maintenance and maintenance of equipment is a very important factor affecting the qualification rate of ...Read more -

Discuss the functional relationship between the three departments of factory production, quality and technology

In general, there are mutual buck-passing and wrangling between various departments on the factory site, which not only affects the output and quality, but also affects the harmonious working relationship between departments. To investigate the root cause, I think it is mainly due to the deviatio...Read more -

The chief technical engineer has many years of experience and 6 suggestions for controlling product quality!

“Product quality is everyone’s responsibility”, high-quality products are produced, managed and controlled, not tested. “Product quality control is a headache for every enterprise”, quality control is a systematic project with its own laws and unique control methods;...Read more -

CNC programming engineer factory technical specification

1. Clarify the responsibilities of the programmer, and be responsible for the control of processing quality, processing efficiency, cost control, and error rate in the mold CNC manufacturing process. 2. When the programmer receives a new mold, he must understand the requirements of the mold,...Read more -

Is it necessary to warm up the CNC machine every morning when it is turned on?

The factory uses precision CNC machine tools (machining center, EDM, slow wire walking and other machine tools) for high-precision machining. Do you have such experience: start up for processing every morning, the machining accuracy of the first piece is often not good enough; The accuracy of the...Read more -

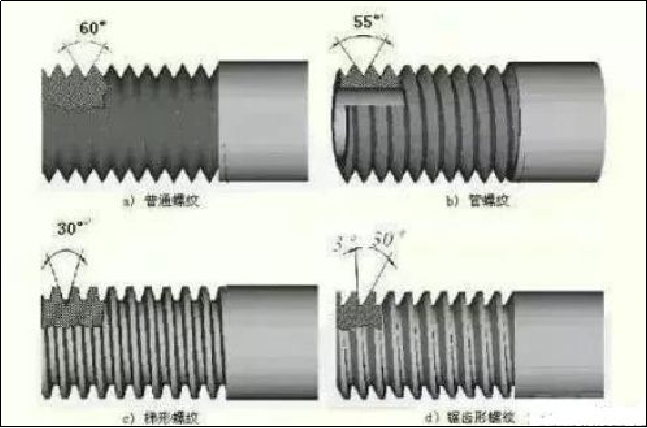

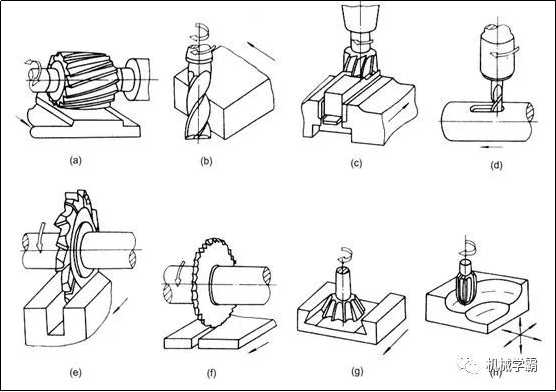

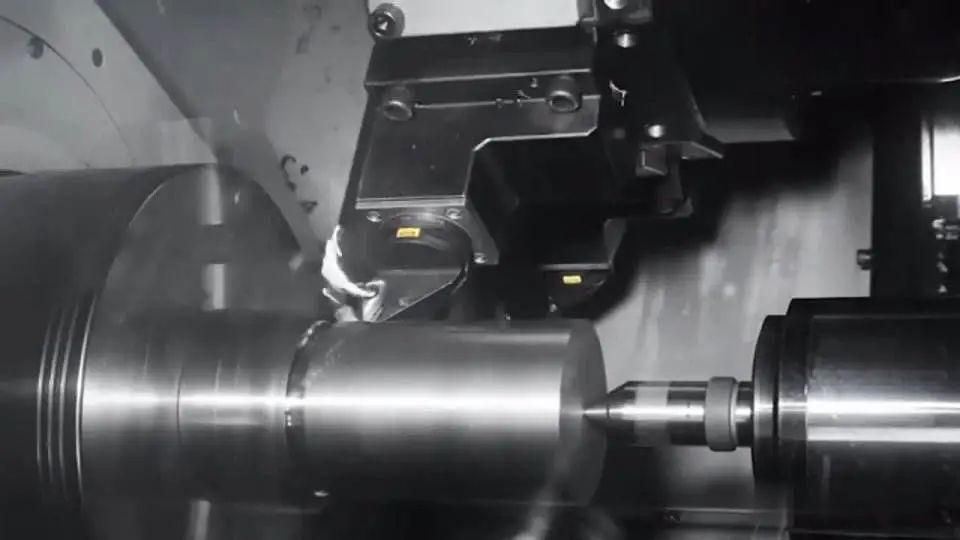

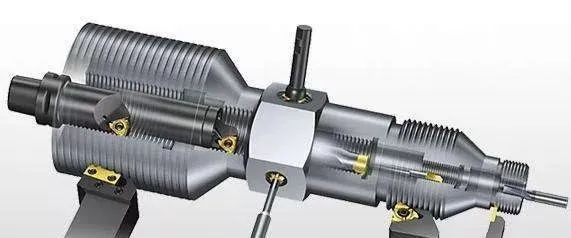

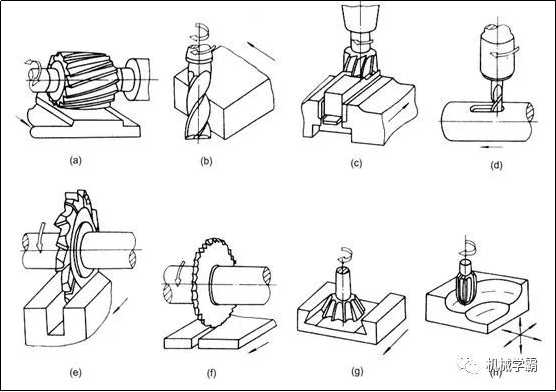

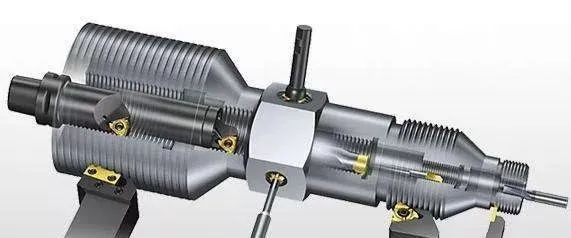

Summary of eight processing methods of thread, you must know when doing machining

Summary of eight processing methods of thread, you must know when doing machiningThe English word corresponding to screw is Screw. The meaning of this word has changed a lot in recent hundreds of years. At least in 1725, it means “mating”.The application of the thread principle can be...Read more