News

-

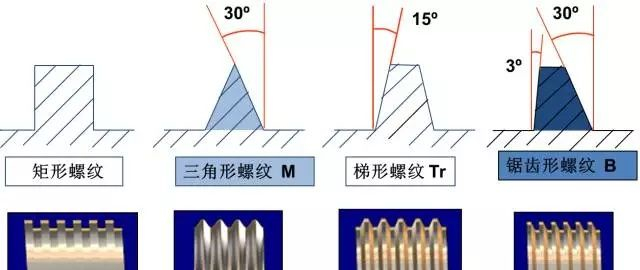

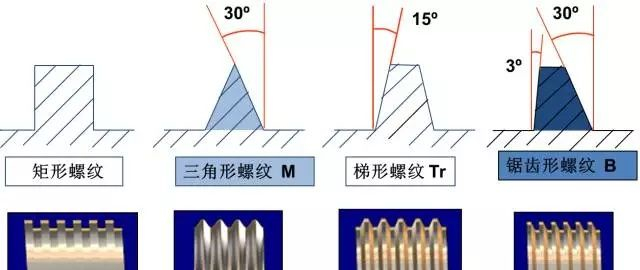

Elements of thread

Elements of thread The thread includes five elements: profile, nominal diameter, number of lines, pitch (or lead), and direction of rotation. 1. tooth type The profile shape of the thread is called the profile shape on the section area passing through the thread axis. There are triangle, trapezoi...Read more -

7 Thread Processing Methods

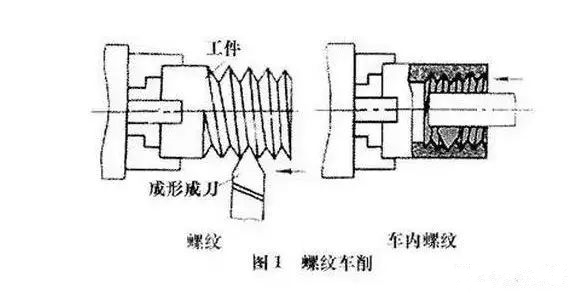

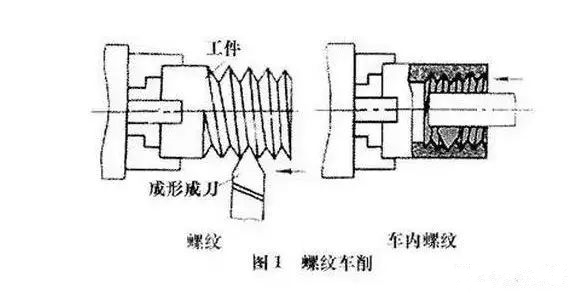

1. Thread cutting Generally, it refers to the method of machining thread on workpiece with forming tool or grinding tool, mainly including turning, milling, tapping and threading grinding, grinding and whirlwind cutting, etc. When turning, milling and grinding the thread, the transmission chain o...Read more -

The method of processing various internal and external threads with thread processing tools.

1 thread cutting Generally, it refers to the method of machining thread on workpiece with forming tool or grinding tool, mainly including turning, milling, tapping and threading grinding, grinding and whirlwind cutting, etc. When turning, milling and grinding the thread, the transmission c...Read more -

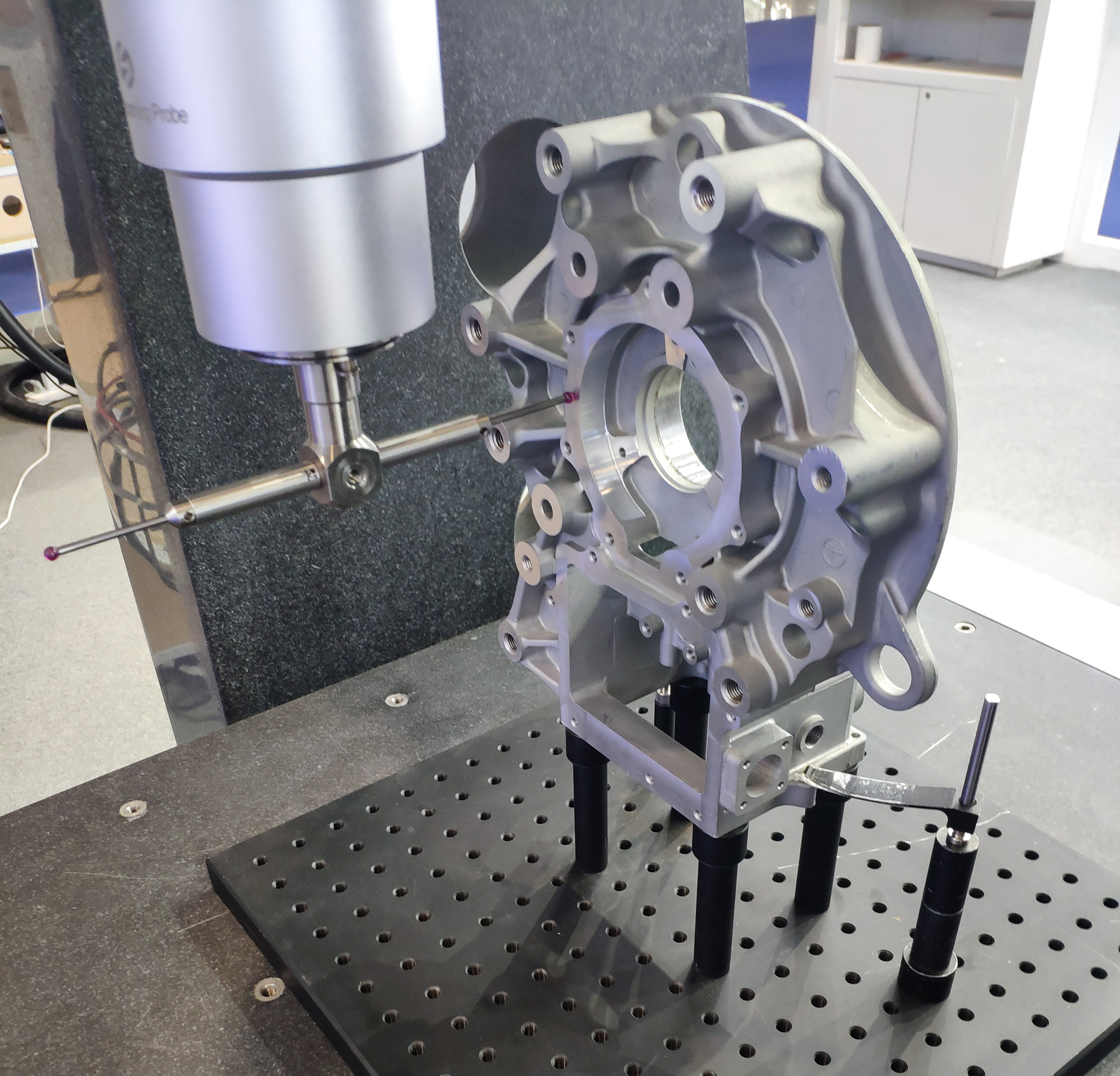

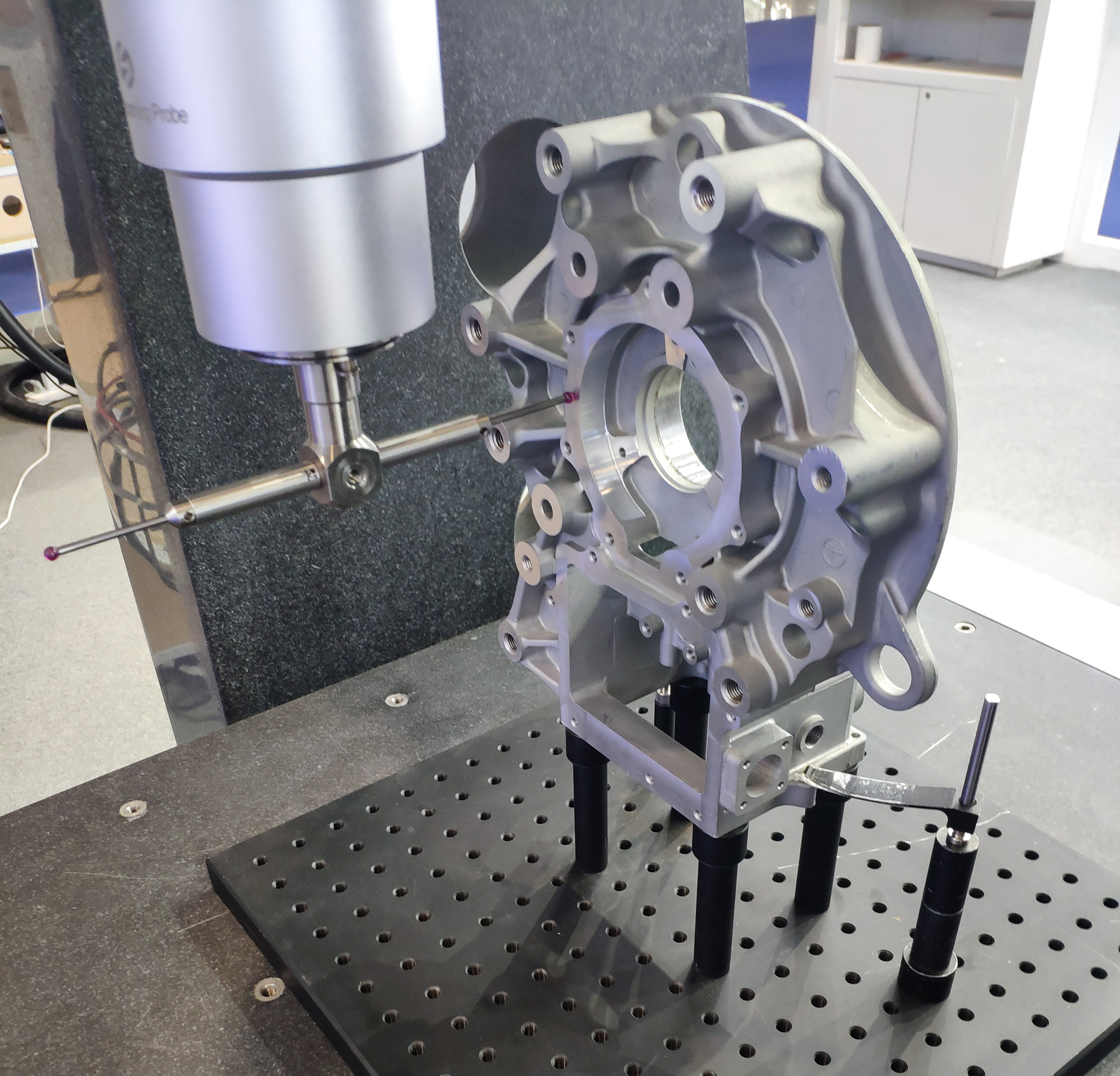

Five important knowledge points of CNC machining, novices need to keep in mind

1. What is the role of the processing program? The machining program list is one of the contents of the NC machining process design. It is also a procedure that requires the operator to follow and execute. It is a specific description of the machining program. The purpose is to let the ope...Read more -

What are the technical requirements for metal stamping?

What are the technical requirements for metal stamping? I. Raw Material Properties of Hardware Stamping Parts 1. Chemical analysis and metallographic examination The content of chemical elements in the material was analyzed, the grain size and uniformity of the material were determined, the gra...Read more -

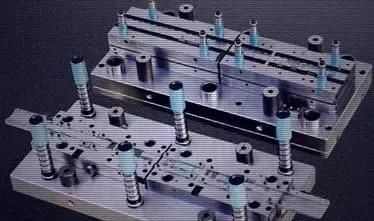

Why is the punch of stamping die easy to break?

Why is the punch of stamping die easy to break? In addition to the punch material and the design of the punch itself, what are the causes of the fracture of the punch? 1. Punch hardness is too high, the material of the punch is not right – change the material of the punch, adjust the hardne...Read more -

Surface Coating Classification

By paint: solvent-based paint coating, electrophoretic coating, powder coating According to painting method: air spraying, airless spraying, electrostatic spraying, electrophoresis According to the coating function: primer coating, intermediate coating, topcoat coating Process: pre-treatme...Read more -

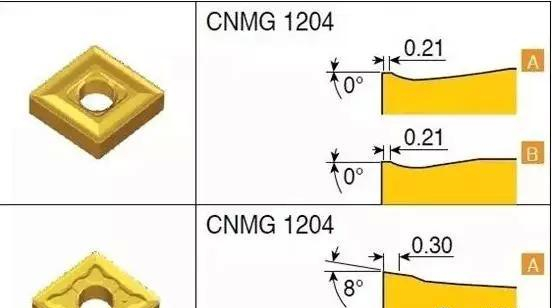

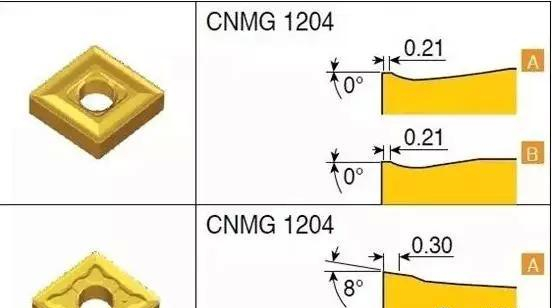

Three simple solutions for turning machining

Effective chip removal avoids scratching the machined surface and prevents chips from getting stuck on the part and the tool before the second cut, so the iron chips should be broken as much as possible so that the production can be smooth and stable. So what should I do once I continue to chip? ...Read more -

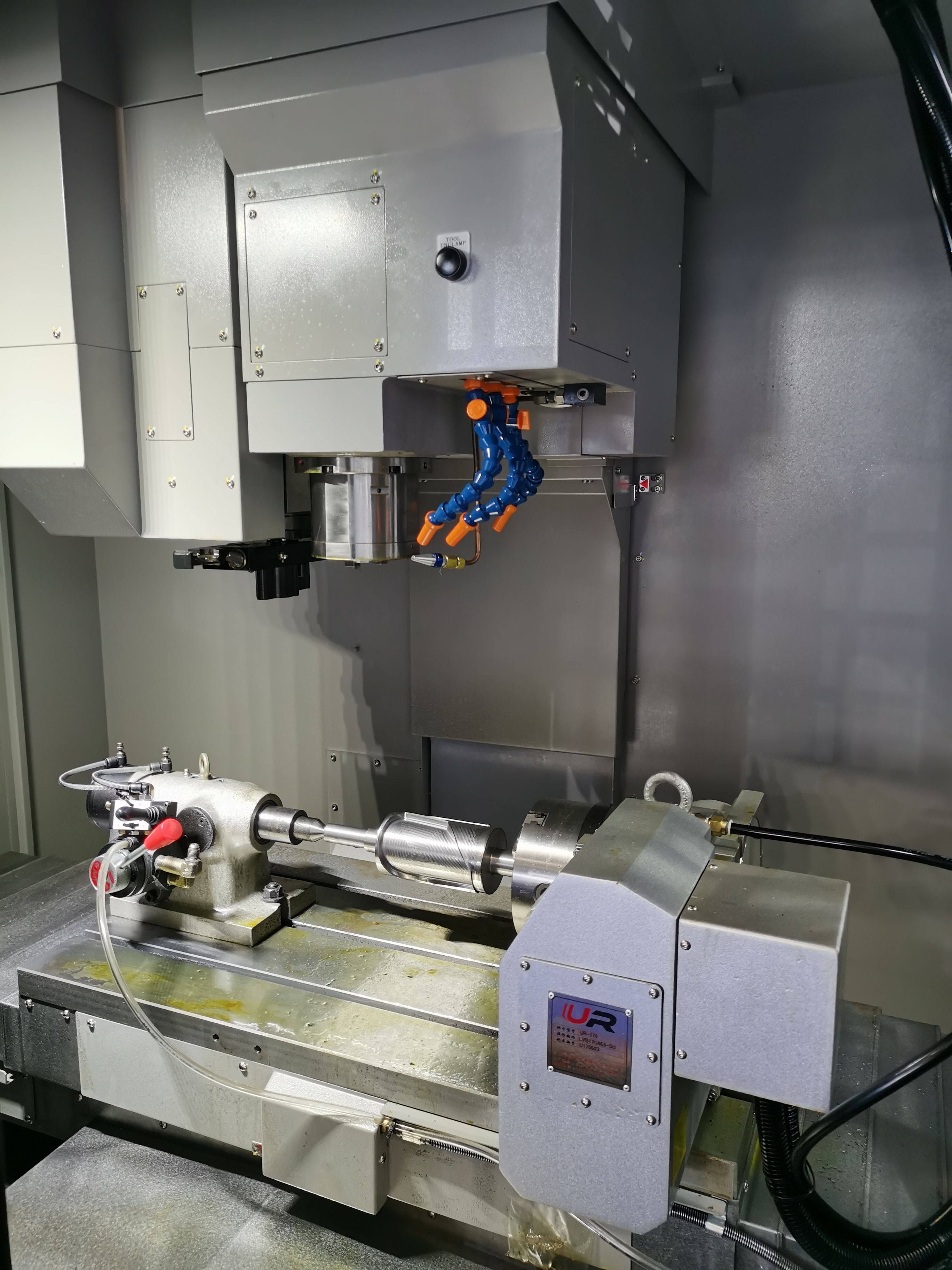

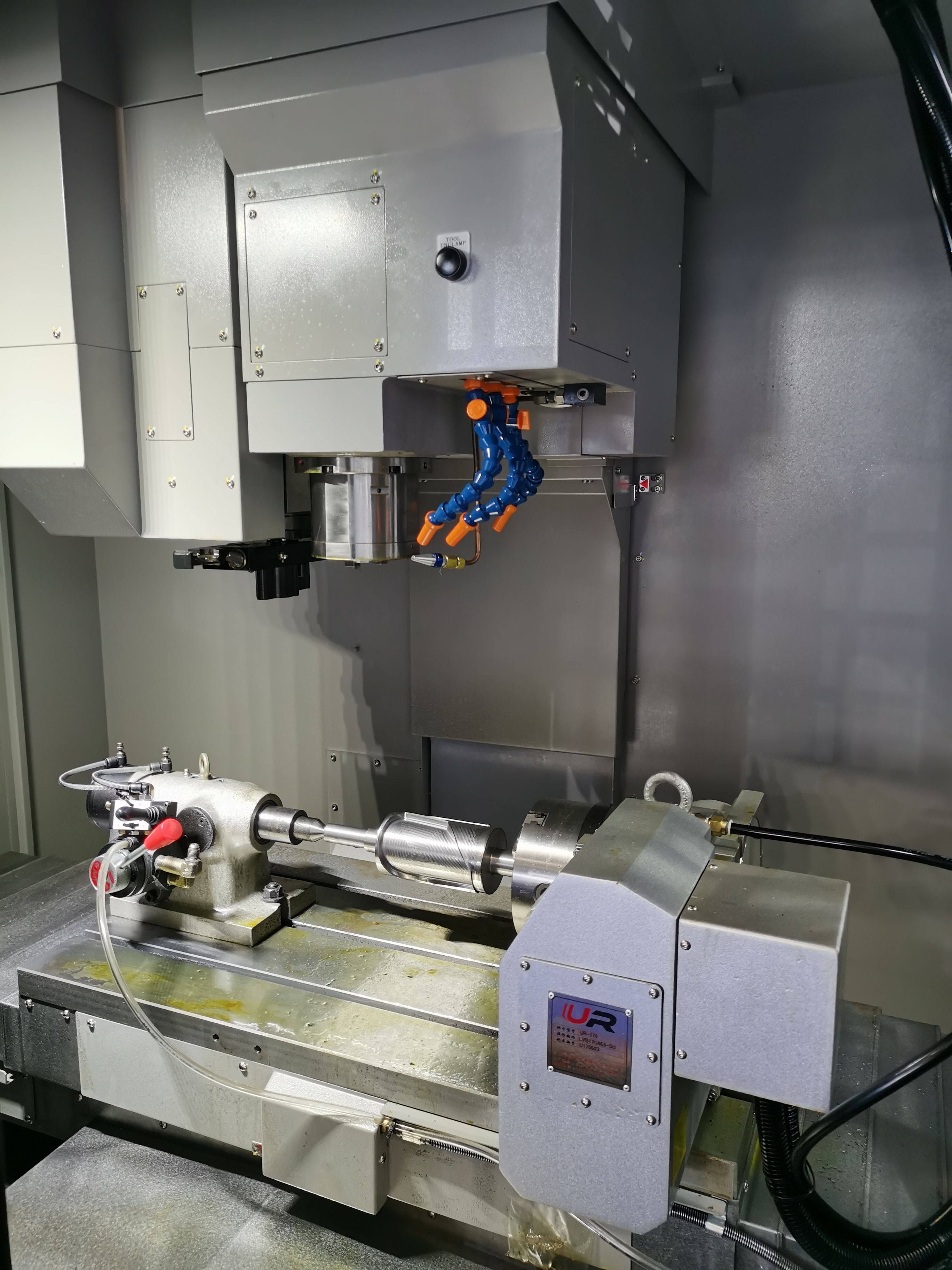

CNC Service — Spline Shaft

The spline shaft is a kind of mechanical transmission. The peace key, the semi-circle key and the oblique key function as the mechanical torque. The outer surface of the shaft has a longitudinal keyway, and the rotating part sleeved on the shaft also has a corresponding keyway, which can b...Read more -

Forging Heating Method

Generally, the forging heating in which the amount of burning loss is 0.5% or less is less oxidative heating, and the heating in which the amount of burning loss is 0.1% or less is referred to as non-oxidizing heating. Less oxidation-free heating can reduce metal oxidation and decarburization, an...Read more -

Thread Milling Cutter

The traditional thread processing method mainly uses a thread turning tool to turn the thread or use taps, die manual tapping and buckle. With the development of CNC machining technology, especially the emergence of three-axis CNC machining system, the more advanced thread machining method –...Read more -

Metal Heat Treatment

The metal heat treatment is to heat the metal or alloy workpiece to a suitable temperature in a certain medium, and after maintaining the temperature for a certain period of time, it is cooled in different media at different speeds, by changing the surface or interior of the metal material. A pro...Read more