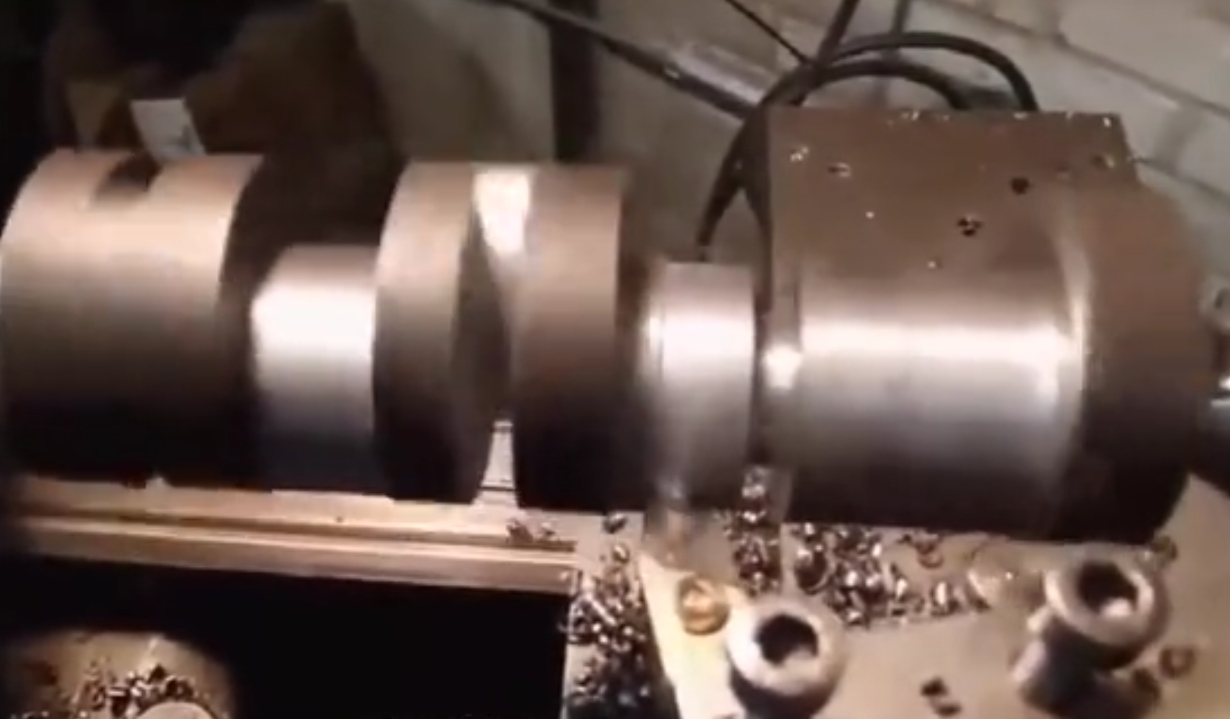

Abubuwa da yawa suna ba da gudummawa ga karkatar da kayan aikin aluminum yayin aikin masana'anta, gami da kaddarorin kayan aiki, sashin lissafi, da sigogin samarwa.

Abubuwan farko sun haɗa da damuwa na ciki a cikin albarkatun ƙasa, murdiya sakamakon ƙarfin injina da zafi, da nakasar da ke haifar da matsa lamba.

1. Tsarin matakai don rage nakasar sarrafawa

1. Rage damuwa na ciki na blank

Za a iya ɗan rage tashin hankali na cikin albarkatun ƙasa ta hanyar tsufa na halitta ko na wucin gadi da hanyoyin girgiza.Yin aiki na farko kuma hanya ce mai yuwuwa.A cikin yanayin albarkatun kasa tare da rataye mai karimci da haɓaka mai yawa, murdiya bayan sarrafawa shima yana da mahimmanci.

Sarrafa rarar rarar kayan da ake amfani da su a baya da kuma raguwar wuce gona da iri na kowane sashe ba zai iya rage gurɓacewar sarrafa kayan aiki a hanyoyin da ke gaba ba, har ma ya ba da izinin ajiye shi na ɗan lokaci bayan sarrafa shi, wanda zai iya ƙara rage wasu daga cikin abubuwan. tashin hankali na ciki.

2. Inganta ikon yankan kayan aiki

Ƙarfin yankewa da yankan zafi a lokacin machining suna tasiri sosai ta hanyar abun da ke ciki da kuma takamaiman siffar kayan aiki.Zaɓin kayan aikin da ya dace yana da mahimmanci don rage murdiya yayin sarrafa sashi.

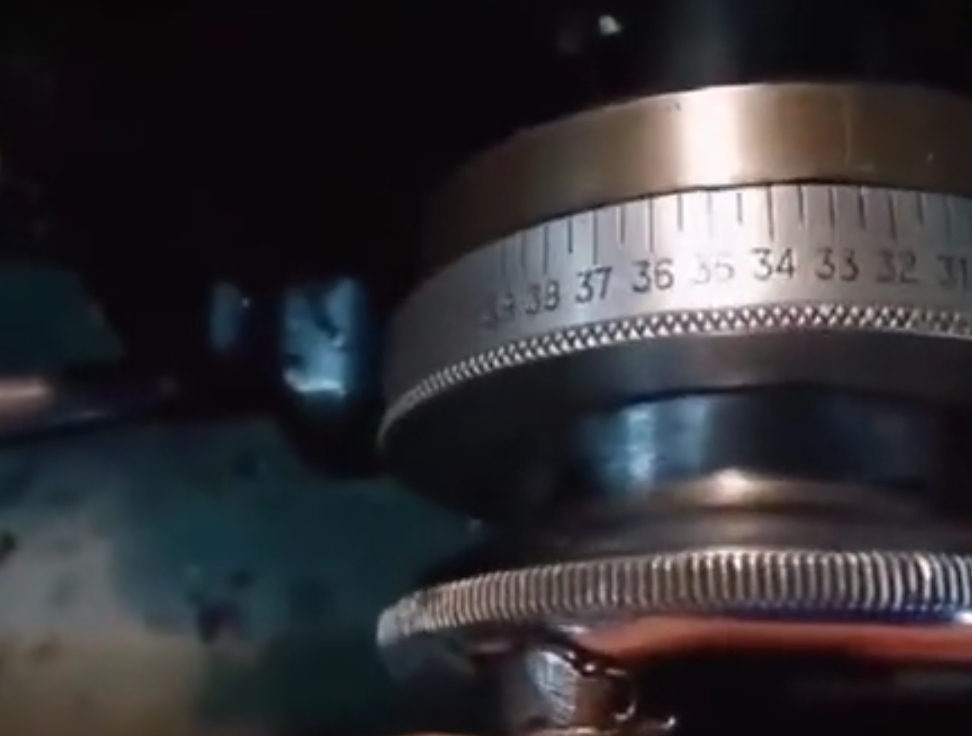

1) Haƙiƙa zaɓi sigogin kayan aiki na geometric.

①Angle Rake yana taka muhimmiyar rawa wajen yanke ayyuka.Yana da mahimmanci a zaɓi babban kusurwar rake a hankali yayin tabbatar da kiyaye ƙarfin ruwan.Babban kusurwar rake ba wai kawai yana taimakawa wajen cimma sakamako mai kyau ba amma kuma yana rage girman yanke yanke kuma yana sauƙaƙe cire guntu mai inganci, yana haifar da raguwar ƙarfi da zafin jiki.Ya kamata a guji kayan aikin da ke da kusurwar rake mara kyau a kowane farashi.

②Angle Relief: Girman kusurwar taimako yana tasiri sosai ga lalacewa a gefe da kuma ingancin injin da aka yi.Zaɓin kusurwar taimako ya dogara da kauri na yanke.A cikin niƙa mai ƙaƙƙarfan, inda akwai ƙimar abinci mai ƙima, nauyi mai nauyi, da haɓakar zafi mai ƙarfi, yana da mahimmanci don tabbatar da ingantaccen zafi daga kayan aiki.Don haka, ya kamata a zaɓi ƙaramin kusurwar taimako.Akasin haka, don niƙa mai kyau, ƙwaƙƙwaran yankewa ya zama dole don rage juzu'i tsakanin gefen gefe da saman injin da aka yi da kuma rage nakasar roba.Saboda haka, ana ba da shawarar mafi girman kusurwar sharewa.

③ Helix kwana: Domin yin milling santsi da kuma rage milling karfi, da helix kwana ya kamata a matsayin babba kamar yadda zai yiwu.

④ Babban kusurwar jujjuyawar: Daidaita rage girman kusurwa na iya inganta yanayin zafi da rage yawan zafin jiki na wurin aiki.

2) Inganta tsarin kayan aiki.

①Don inganta ƙaurawar guntu, yana da mahimmanci don rage yawan haƙora akan abin yankan niƙa kuma ƙara girman guntu sarari.Saboda girman filastik na sassan aluminum, ana samun ƙarar nakasar yankan yayin aiki, yana buƙatar babban guntu sarari.Sakamakon haka, ana ba da shawarar babban radius na ƙasa don guntuwar guntu da rage yawan haƙoran milling.

②Yi madaidaicin niƙa na haƙoran ruwa, tabbatar da cewa ƙarancin ƙimar yankan yana ƙasa da Ra=0.4um.Lokacin amfani da sabuwar wuka, yana da kyau a ɗan niƙa gaba da bayan haƙora ta hanyar amfani da dutse mai kyau don cire duk wani burbushi da ƙananan kurakurai da ka iya haifar da kaifin.Wannan tsari ba kawai yana rage yankan zafi ba amma kuma yana rage yanke nakasar.

③Yana da mahimmanci don saka idanu sosai kan ƙa'idodin lalacewa na kayan aikin yanke.Yayin da kayan aiki ke raguwa, ƙimar ƙarancin kayan aikin yana ƙaruwa, yankan zafin jiki yana ƙaruwa, kuma nakasar aikin aikin yana ƙara bayyana.Baya ga zabar kayan aikin yanke kayan aiki tare da kyakkyawan juriya na lalacewa, yana da mahimmanci don bin iyakar ƙarancin kayan aiki na 0.2mm don hana faruwar haɓakar haɓakar haɓaka.A lokacin yankan ayyukan, ana bada shawara don kula da zafin jiki a ƙasa da 100 ° C don hana nakasawa.

3. Inganta hanyar clamping na workpieces

Don kayan aikin aluminum mai bakin ciki tare da rashin ƙarfi, ana iya amfani da hanyoyin matsawa masu zuwa don rage lalacewa:

①Lokacin da aiki tare da bakin ciki-banga bushing sassa, ta yin amfani da uku-jaw kai tsakiya chuck ko spring chuck zuwa matsa sassa radially iya haifar da workpiece nakasawa a lokacin da loosened bayan aiki.A irin waɗannan lokuta, yana da kyau a yi amfani da hanyar damtse fuska mai ƙarfi na ƙarshen axial.Fara ta hanyar gano rami na ciki na ɓangaren, ƙirƙirar madaidaicin madauri na al'ada, da saka shi cikin rami na ciki.Yi amfani da farantin murfin don shafa matsi zuwa ƙarshen fuska, sa'an nan kuma ajiye shi a wuri tare da goro.Ta hanyar amfani da wannan hanyar, zaku iya hana nakasar matsewa yayin sarrafa da'irar waje, wanda zai haifar da ingantacciyar daidaiton aiki.

②Lokacin da aiki tare da bakin ciki-bango sassa karfe sassa, yana da kyau a yi amfani da Magnetic clamping fasahar don cimma uniform clamping ƙarfi, guda biyu tare da mafi kyau yankan sigogi.Wannan hanya ta yadda ya kamata yana rage haɗarin nakasar kayan aiki yayin aiki.A madadin, ana iya aiwatar da tallafin ciki don haɓaka kwanciyar hankali na abubuwan da ke da bangon bakin ciki.

Ta hanyar shigar da kayan aiki tare da matsakaicin tallafi, kamar maganin urea mai ɗauke da 3% zuwa 6% potassium nitrate, ana iya rage yiwuwar nakasar yayin datsewa da yanke.Ana iya narkar da wannan filar daga baya kuma a cire shi ta hanyar nutsar da aikin a cikin ruwa ko barasa bayan aiwatarwa.

4. Shirya tsari a hankali

A yayin da ake yin babban saurin yankewa, aikin niƙa yana da saurin girgiza saboda ƙaƙƙarfan iznin injina da yankan tsaka-tsaki, wanda ke haifar da mummunan tasiri akan daidaiton injina da rashin ƙarfi na saman.Sakamakon haka, hanyar yanke babban sauri ta CNC yawanci ta ƙunshi matakai daban-daban, wato m machining, Semi-karewa, tsaftace kusurwa, da gamawa, da sauransu.

A cikin al'amuran da abubuwan da aka gyara suna buƙatar daidaito mai girma, yana iya zama dole a aiwatar da ƙarshen kammala na biyu tare da kammalawa.Bayan m machining, yana da fa'ida don ƙyale sassan su sha sanyi na halitta don rage damuwa na ciki da ke haifar da mashin ɗin da kuma rage nakasawa.Gefen da aka bari bayan m machining ya kamata ya wuce matakin nakasawa, yawanci jere daga 1 zuwa 2 mm.

Bugu da ƙari, lokacin gudanar da kammalawa, yana da mahimmanci don riƙe daidaitaccen izinin yin injin a kan ƙarshen ɓangaren ɓangaren, yawanci jere daga 0.2 zuwa 0.5mm.Wannan aikin yana tabbatar da cewa kayan aikin ya kasance cikin kwanciyar hankali yayin sarrafawa, don haka yana rage girman nakasu, samun ingantaccen ingancin sarrafa saman, da kuma tabbatar da daidaiton samfur.

2. Ayyukan aiki don rage nakasar sarrafawa

Sassan da aka yi dagacnc machined aluminum sassasun lalace yayin aiki.Baya ga dalilan da ke sama, hanyar aiki kuma tana da mahimmanci a cikin ainihin aiki.

1. Don abubuwan da aka haɗa tare da ƙwaƙƙwaran machining izni, yana da mahimmanci a yi amfani da dabarun sarrafa ma'auni don haɓaka ɓarkewar zafi yayin injina da hana haɗuwar zafi.A matsayin misali, lokacin rage takardar kauri na 90mm zuwa 60mm, a niƙa gefe ɗaya sannan a niƙa ɗayan nan da nan, sannan tsarin girman girman ƙarshe ɗaya ya biyo baya yana haifar da fa'ida ta 5mm.Sabanin haka, yin amfani da maimaita aikin daidaitawa, tare da niƙa kowane gefe a matakai biyu, yana tabbatar da girman ƙarshe tare da lebur na 0.3mm.

2. Idan akwai indentations da yawa akan ɓangaren farantin, ba a ba da shawarar yin amfani da hanyar sarrafa mataki-mataki don kowane shigarwar mutum ba.Wannan na iya haifar da rarraba damuwa na yau da kullun da nakasar bangaren na gaba.Madadin haka, yi la'akari da aiwatar da aiki mai yuwuwa don injin duk abubuwan shiga lokaci guda akan kowane Layer, kafin matsawa zuwa Layer na gaba.Wannan zai taimaka tabbatar da ko da rarraba damuwa da kuma rage nakasawa.

3. Don rage ƙarfin yankewa da zafi, za'a iya daidaita adadin yankan.Daga cikin uku na abubuwan yanke adadin, adadin yankan baya yana tasiri sosai ga yanke ƙarfi.Yawan izinin injina da yanke ƙarfi na iya haifar da nakasu ga ɓangaren, da yin sulhu da rigidity na kayan aikin injin, da rage ƙarfin kayan aiki.Rage adadin yankan baya na iya rage yawan aikin samarwa.Duk da haka, niƙa mai sauri a cikin injinan CNC na iya magance wannan batu.Ta hanyar rage adadin yankan baya a lokaci guda da haɓaka ciyarwar abinci da saurin kayan aikin injin, za a iya rage ƙarfin yanke yayin da ake kiyaye ingancin sarrafawa.

4. Ya kamata kuma a ba da hankali ga jerin yanke.A cikin ingantattun mashin ɗin, abin da aka fi mayar da hankali shi ne kan haɓaka aikin sarrafawa da kuma ƙoƙarin kawar da mafi girman kayan kowane raka'a na lokaci.Gabaɗaya, an fi son yin niƙa.Wannan yana nufin cewa an cire rarar kayan da ke saman kayan aikin a cikin mafi girman gudu kuma a cikin mafi ƙarancin lokacin da zai yiwu don kafa jigon jigon da ake buƙata don kammalawa.A gefe guda, tsarin gamawa yana ba da fifiko ga daidaito da inganci mafi girma, don haka ana ba da shawarar ƙasa milling.Yayin da kaurin kauri na kayan aiki yana raguwa a hankali daga matsakaicin zuwa sifili yayin saukar niƙa, yana rage ƙarfin aiki sosai kuma yana rage ɓarna sashi.

5. Nakasar kayan aiki na bakin ciki da ke haifar da matsewa yayin sarrafawa lamari ne da babu makawa, koda bayan an gama su.Don rage girman nakasar aikin, ana ba da shawarar a saki matsa lamba kafin a gama don cimma ma'auni na ƙarshe.Wannan yana bawa aikin aikin damar komawa ta dabi'a zuwa siffarsa ta asali.Daga baya, matsa lamba za a iya taka tsantsan tightness har sai workpiece ne cikakken clamped, cimma da ake so sarrafa sakamako.Da kyau, ya kamata a yi amfani da ƙarfin matsawa zuwa saman mai goyan baya, daidaitawa tare da rigidity na aikin.Duk da yake tabbatar da cewa kayan aikin ya kasance amintacce, yana da kyau a yi amfani da ƙarfin matsawa kaɗan.

6. Lokacin yin sassa tare da sarari mara kyau, yana da kyau a guje wa abin yankan niƙa shiga cikin ɓangaren kai tsaye zuwa rawar soja yayin aiwatarwa.Wannan na iya haifar da iyakataccen wurin guntu don mai yankan niƙa, ƙauracewa guntu mai cikas, da sakamakon zafi mai zafi, faɗaɗa, da lalacewar sassan.Abubuwan da ba a so kamar murdiya da karya kayan aiki na iya faruwa.Ana ba da shawarar da farko a yi amfani da ɗan ƙaramin digon diyar mai girman daidai ko ɗan girma fiye da abin yankan niƙa don ɗaukar ramin sannan daga baya a yi amfani da abin yankan niƙa don yin inji.A madadin, ana iya samar da shirin yankan karkace ta amfani da software na CAM.

Kalubale na farko da ke tasiri daidaitaccen ƙirƙira ɓangaren alluminium da ingancin ƙarshensa shine yuwuwar waɗannan sassan zuwa murdiya yayin sarrafawa.Wannan yana buƙatar ma'aikaci ya mallaki takamaiman matakin ƙwarewar aiki da ƙwarewa.

Anebon ya dogara da ƙarfin fasaha mai ƙarfi kuma yana ƙirƙira ingantattun fasahohi don biyan buƙatun injin ƙarfe na cnc,5 axis cnc millingda kuma simintin mota.Duk ra'ayoyin da shawarwari za a yaba sosai!Kyakkyawan haɗin gwiwa zai iya inganta mu duka zuwa mafi kyawun ci gaba!

ODM Manufacturer ChinaMusamman sassan CNC na aluminumA halin yanzu, an fitar da kayayyakin Anebon zuwa kasashe sama da sittin da yankuna daban-daban, kamar su kudu maso gabashin Asiya, Amurka, Afirka, Gabashin Turai, Rasha, Kanada da dai sauransu. duka a kasar Sin da sauran sassan duniya.

Idan kuna son ƙarin sani game da mu ko kuna son yin tambaya, da fatan za a aiko da imel zuwa gainfo@anebon.com

Lokacin aikawa: Fabrairu-02-2024