Nawa kuka sani game da ƙirar injina?

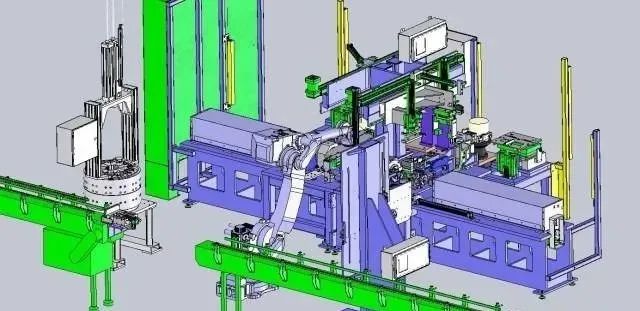

Ya ƙunshi ƙira, nazari da haɓaka abubuwa daban-daban na inji don saduwa da ƙayyadaddun bayanai da buƙatun da ake so.Ya ƙunshi ƙira, nazari, da haɓaka abubuwa daban-daban na injina don saduwa da ƙayyadaddun ƙayyadaddun bayanai da buƙatun da ake buƙata.Kira na injina na iya haɗawa da wurare da yawa, gami da ƙirar samfura, ƙirar injin, ƙirar kayan aiki, da ƙirar tsari.Ana buƙatar fahimta da amfani da ƙa'idodin injiniya na asali kamar thermodynamics da kimiyyar kayan aiki.

Zane-zanen injiniya wani ɓangare ne na ƙira, ƙira, amfani da tsarin kulawa.Sakaci a cikin ƙira koyaushe zai yi tunani akan waɗannan bangarorin.Ba shi da wahala a tantance ko aikin zai yi nasara ko kuma ya gaza.Ƙirƙira yana da tasiri mai girma akan tsarin ƙira, don haka ƙira mai kyau ba ta bambanta da masana'anta ba.Fahimtar masana'anta zai taimaka muku haɓaka ƙwarewar ƙirar ku.

Tsarin injina ya fi damuwa da samar da abin dogaro, masu tsada, da ingantattun mafita.Masu zanen kaya sukan yi amfani da software da kayan aiki na kayan aiki na kwamfuta (CAD) don haɓaka cikakkun samfura, gudanar da simulations, da kimanta aikin kafin masana'anta.A cikin tsarin ƙira, masu zanen injin suna la'akari da dalilai kamar aminci, aminci, ƙira, ergonomics, aesthetics, da muhalli. tasiri.Don tabbatar da haɗin kai da aiki mara kyau, suna aiki tare da sauran nau'o'in injiniya kamar injiniyan farar hula, masana'antu, da na lantarki.

Babu mutane da yawa da na gani waɗanda nan da nan za su iya haɗawa da sarrafa zanen bayan an sanya su cikin samarwa.A lokacin aikin nazarin zane da kuma tsari na gaba, ba sabon abu ba ne don samun matsaloli masu yawa.Wannan ya haɗa da zanen da ake kira manyan injiniyoyi ko manyan injiniyoyi suka ƙirƙira.Wannan shi ne sakamakon bayan tattaunawa akai-akai da tarurruka da yawa.Wannan ya faru ne saboda abubuwa da yawa.A gefe guda akwai daidaituwa a cikin zane, da matakin mai kallo.Amma rashin fahimtar mai tsara tsarin masana'antu a gefe guda shine babban dalilin.

Ta yaya kuke sanin nawa kuka sani game da masana'anta?

Dauki zanen abin da kuka tsara.Menene dukan tsarin masana'antu?Ba shi yiwuwa a yi simintin gyare-gyare, ƙirƙira da juyawa.Nika, shiryawa da niƙa kuma ba su yiwuwa.Duk wanda ya yi aiki na shekaru da yawa a shagon injin ya san wannan.Don cikakken fahimtar tsarin, dole ne a karya shi cikin ƙananan matakai.Tsarin ɓangaren na iya haifar da haɗari yayin maganin zafi.Yana da mahimmanci a san yadda za a inganta shi da yadda za a yanke kayan.Ana amfani da hangen nesa don daidaita tsarin, wanda ya haɗa da adadin wukake, saurin juyawa, adadin kayan aikin kayan aiki, har ma da jagorancin da aka jefar da kwakwalwan ƙarfe, tsari na yin amfani da wukake, da kuma aiki na lathe.Za mu iya cewa yanzu muna da tushe mai ƙarfi.

Ka'idodin don zaɓar kayan don sassa na inji

yakamata yayi la'akari da abubuwa uku na buƙatu

1. Bukatun amfani (la'akari na farko):

1) Yanayin aiki na sassa (vibration, tasiri, babban zafin jiki, ƙananan zafin jiki, babban gudu, da babban kaya ya kamata a bi da su tare da taka tsantsan);2) Iyakance akan girman da ingancin sassan;3) Muhimmancin sassan.(Muhimmancin dangi ga amincin duka na'ura)

2. Abubuwan da ake buƙata:

1) Ƙirar ƙura (simintin gyare-gyare, ƙirƙira, yankan faranti, yankan sanda);

2) sarrafa injina;

3) Maganin zafi;

4) Maganin saman

3. Bukatun tattalin arziki:

1) Farashin kayan aiki (kwatanta tsakanin farashi mara kyau da farashin sarrafawa na yau da kullun na karfe da bayanan sanyi, ƙayyadaddun simintin gyare-gyare, da ƙirƙira daidaitaccen ƙirƙira);

2) Gudanar da girman tsari da farashin sarrafawa;

3) Yawan amfani da kayan aiki;(kamar ƙayyadaddun faranti, sanduna, da bayanan martaba, yi amfani da su daidai)

4) Sauya (kokarin yin amfani da kayan arha don maye gurbin kayan da ba kasafai masu tsada ba kamar tawada ductile don maye gurbin hannun tagulla a wasu sassa masu jure lalacewa ko ɓangarorin mai ɗauke da mai a maimakon wasu hannayen riga da nailan a yanayin ƙananan kayan aiki) Sauya ƙarfe gears tare da kayan tsutsa na jan karfe da sauransu.

Har ila yau, la'akari da samuwan kayan gida

1. Abubuwan buƙatu na asali don ƙirar injiniya

a) Kula da daidaituwa da daidaituwa game da buƙatun aikin injin!Hana tasirin ganga daga faruwa

b) Bukatun tattalin arzikin na'ura: Tsarin tattalin arziki, shigar da shi cikin sauri da sauri, dawo da amfani yayin haɓakawa, har ma da ƙira-ƙira a lokaci guda don tattalin arziki.Wannan zai ba ku mafi kyawun farashi / ƙimar aiki (samfurin farawa a cikin ƙananan batches).

2. Abubuwan buƙatu na asali don ƙirar sassa na injiniya

a) Yin aiki akai-akai da dogaro a cikin lokacin aiki da aka tsara don tabbatar da ayyuka daban-daban na injin;

b) Rage farashin samarwa da masana'anta na sassa;

c) Yi amfani da daidaitattun sassa na yau da kullun a kasuwa gwargwadon yiwuwa;

d) Lokacin zayyana samfuran da za a iya jera su, yi la'akari da versatility na sassa.Tsarin waɗanda ba na duniya ba ya kamata ya kasance daidai da iyakar iyakar da zai yiwu don rage rikitaccen tsarin masana'antu, da lokacin da ake buƙata don tsarawa da kayan aiki.

Duba zaɓi na al'ada sassa a zanen inji

Siffar tsarin sashe shine babban abin da ke ƙayyade tsarin magana don kallon ɓangaren.Sassan da ke da siffofi iri ɗaya suna raba halaye gama gari.

Gabaɗaya, ana iya raba sassan injin zuwa nau'ikan bisa la'akari da surar su, kamar bushings da fayafai na ƙafafu.Ga halayensu da aka bayyana ta hanyoyi daban-daban:

(1) Zaɓi abubuwan shaft da hannun riga

Axis na shafts ko ɓangaren hannun hannu yana a kwance a tsaye gwargwadon matsayinsa na sarrafawa.Gabaɗaya, ra'ayi na asali da ƙetarewa, da kuma juzu'i mai girma, duk abin da ake buƙata.

(2) Bincika zaɓin sassan dabaran da faifai

A cikin babban ra'ayi, axis kuma an sanya shi a kwance bisa ga matsayi na sarrafawa.Wannan yana buƙatar ra'ayoyi na asali guda biyu.

(3) Bangaren cokali mai yatsu da sanda

Forks da sanduna, alal misali, ana yawan lanƙwasa da karkatar da su.Za a yi amfani da ra'ayin da ya fi dacewa da halayen siffar su a matsayin babban hoton.Hakanan ana iya buƙatar hotuna na asali biyu ko fiye.

(4) Zaɓin sassan akwatin

Abubuwan nau'in akwatin sun fi rikitarwa.Dole ne babban wurin ra'ayi ya dace da matsayin aiki na sashi akan na'ura.Gabaɗaya, ana buƙatar aƙalla ra'ayoyi na asali guda uku.

Sau da yawa akan sami mabambantan tsare-tsaren magana daban-daban don sashi ɗaya.Kowannensu yana da nasa amfaninsa da nasa kura-kurai don haka a kwatanta shi da nazari dalla-dalla.

Lokacin zabar ra'ayoyi, yana da mahimmanci cewa kowane ra'ayi yana da fifiko na musamman.Ya kamata ra'ayin da aka zaɓa ya zama cikakke kuma a bayyane, kuma mai sauƙin karantawa.

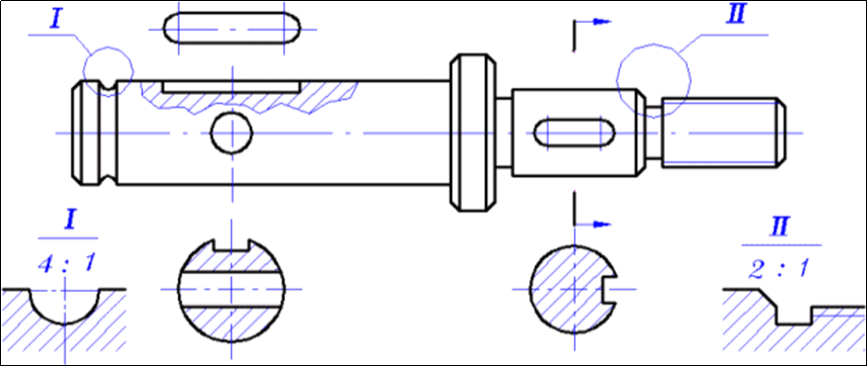

Shaft da hannayen riga sassa

Babban maƙasudin abubuwan shaft da hannun riga shine watsa wutar lantarki, ko tallafawa wasu sassa kamar ramuka.

(1) Halayen tsari da hanyoyin sarrafawa don abubuwan shaft da hannayen riga

Babban abubuwan da ke cikin waɗannan jikin masu jujjuya su ne silinda, mazugi da sauran jujjuyawar jiki masu girma dabam dabam.Ana sarrafa galibin sassan shaft da hannun riga ta amfani da lathes ko injin niƙa.Wadannanauto kayayyakin gyaragalibi ana tsara su, sarrafa su ko haɗa su tare da sifofi kamar chamfers da zaren.Hakanan suna iya samun ƙulle-ƙulle, ramuka, maɓalli ko saman filaye.

(2) Duba zaɓi

An wakilta sashin shaft da hannun riga tare da hangen nesa na gaba, an sanya axis a kwance.Wannan yana biye da lambar da ta dace ko madaidaicin sashe da faɗaɗa ra'ayi.Matsayin kwance na babban ra'ayi ya dace ba kawai tare da ka'idar fasalin don zaɓin ra'ayi na ɓangaren ba amma har ma tare da matsayi na aiki da matsayi na aiki.

Za a iya amfani da sassan sassa don wakiltar tsarin kamar ramuka da ramuka a cikin ramin.Kamar yadda aka nuna a cikin Hoto na 3-7, hanyoyin maɓalli, ramuka da jirage masu tsari, a tsakanin sauran sifofi, suna buƙatar wakilcin ra'ayi daban-daban.

Ƙaƙƙarfan raƙuman ruwa ba sa buƙatar yankewa, amma kayan aikin hannu dole ne su nuna tsarin su na ciki.Ana iya amfani da cikakken ra'ayi na sashe idan nau'in waje yana da sauƙi;Ana iya amfani da ra'ayoyin rabin sashe idan yana da rikitarwa.

Hoto 3-7 Hanyar magana axis

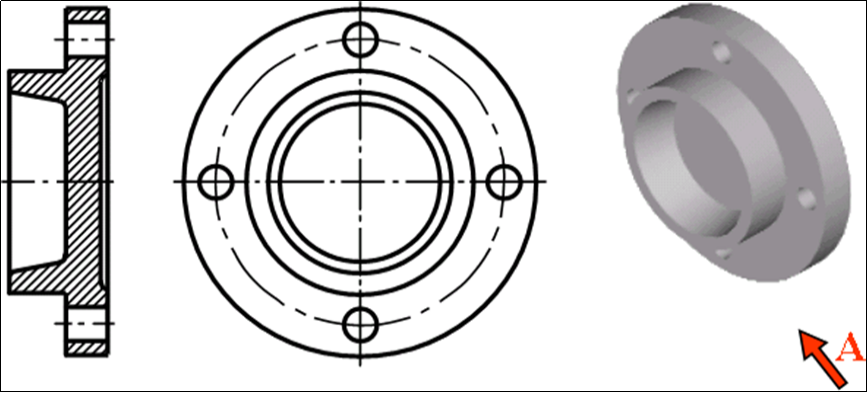

Pan da murfin sassa

Haɗe a cikin faifai da sassan murfin akwai murfin ƙarshen, flanges (wheels), jakunkuna, da sauran sassa masu siffar diski.Ana amfani da ƙafafu don isar da wuta kuma murfin yana aiki galibi azaman tallafi, matsayi na axial, da hatimi.

1. Tsarin fasali

Babban jikin faifai ko ɓangaren murfin yawanci jujjuyawa ce ta coaxial.Wasu suna da manyan jikkuna masu murabba'i, rectangular, ko wata siffa, tare da mafi girma radial da ƙananan ma'auni.Kamar yadda aka nuna a cikin Figures 3-8, sassa sukan ƙunshi sifofi kamar ramukan ramuka, ramuka tare da kewayen ɓangaren, hakarkari ko tsagi, da hakora.

Hoto 3-8 Hanyar Magana na faranti / sassa na murfin

(2) Duba zaɓi

Yawancin lokaci, faifai da sassan murfin za a iya bayyana su ta fuskoki biyu na asali.Babban ra'ayi shine cikakken sashin giciye ta hanyar axis.Ya kamata a sanya axis a kwance don dacewa da matsayin sarrafa shi.Babban ra'ayi na wasu sassa, waɗanda ba a sarrafa su da farko ta hanyar lathes ana iya ƙididdige su bisa ga siffarsu da matsayinsu.

Mahimmin ra'ayi na faifai da murfin hanya ce ta bayyana rarraba ramuka, ramuka da sauran tsarin da ke kewaye da faifai ko murfin.Lokacin da ra'ayi ya yi daidai, ana iya amfani da kallon rabin sashe.

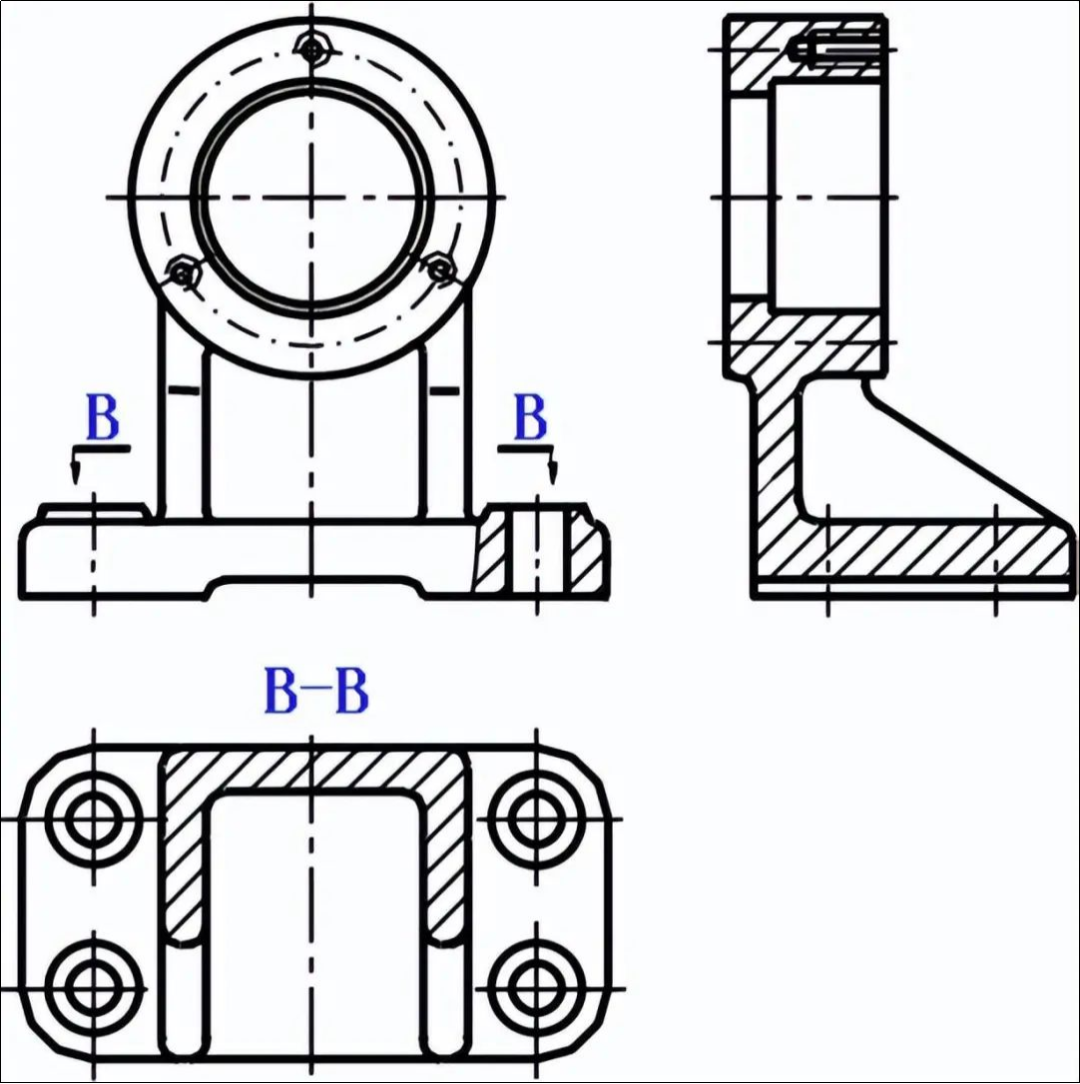

cokali mai yatsu da sassan sassa

Ƙungiyoyin firam da cokali mai yatsa sun haɗa da sanduna masu haɗawa, maƙallan da sauransu don dalilai daban-daban.Cokali mai yatsa da sandunan ɗaure suna taka muhimmiyar rawa a cikin tsarin sarrafa na'ura.Brackets suna yin irin wannan manufa.Waɗannan guraben yawanci ana jefawa ko ƙirƙira.

(1) Siffofin tsari

Yawancin cokali mai yatsu da firam ɗin sun ƙunshi sassa uku: ɓangaren aiki, ɓangaren shigarwa, da ɓangaren haɗawa.Sashin aiki yana nufin ɓangaren cokali mai yatsu ko firam wanda ke da tasiri akan wasu sassa.Ana amfani da ramukan hawa akan farantin ƙasa mai rectangular na sashi don matsayi da haɗa maƙallan.Farantin goyan bayan sashin yana haɗa sassan aiki da shigarwa.Lokacin zayyana sassan sashi, ya zama ruwan dare don gina sassan aiki da shigarwa na farko, sannan ƙara ɓangaren haɗin gwiwa.

(2) Duba zaɓi

Yawancin cokali mai yatsu da firam ana yin su ta hanyoyi masu sarkakiya, tare da lanƙwasa ko lanƙwasa.Sassan suna fuskantar matakai daban-daban na sarrafawa, kuma wuraren aiki na waɗannan sassan ba a daidaita su ba.Gabaɗaya, ra'ayi wanda ya fi dacewa ya nuna halayen sifofin abu an zaɓi shi azaman babban hoto.Sauran ra'ayoyi, ra'ayi na yanki, sassan giciye, da sauran hanyoyin magana, ban da manyan ra'ayoyi, an zaɓi su ne bisa halayen tsarin sa.Kamar yadda aka nuna a hoto na 3-9.

Hoto 3-9 Hanyar Magana na sassan sashi

Sassan Akwatin

Sassan akwatin sun haɗa da jikunan famfo, jikin bawul, wuraren injina, akwatunan ragewa, da sauransu. Ana amfani da simintin gyare-gyare don yin sassan akwatin, waɗanda sune manyan abubuwan injina da abubuwan haɗin gwiwa.Ana amfani da goyan baya, hatimi, da matsayi akai-akai.

1. Tsarin fasali

Tsarin akwatin ya bambanta bisa ga bukatun aiki.Duk da haka, yawancin bawo ne da ke da manyan kogo na ciki.An ƙaddara siffar rami na ciki ta hanyar motsin motsi da siffarkayan aikin injindauke a cikin akwatin.Ramin mai ɗaukar hoto shine ɓangaren da ke goyan bayan sassa masu motsi na akwatin.Ƙarshen fuskar ramin yana da tsarin aiki na gida, kamar jirgin sama don shigar da murfin ƙarshen ko dunƙule ramuka.

(2) Duba zaɓi

Matsayin sarrafawa don kowane matakai sun bambanta.Sassan akwatin suna da rikitattun fasalulluka da hanyoyin sarrafawa masu rikitarwa.Babban ra'ayi yawanci ana zaba bisa ga matsayin aiki na akwatin da siffofin siffarsa.Don bayyana rikitattun siffofi na ciki da na waje, wajibi ne a sami isasshen adadin zane-zane da zane-zane.Za'a iya amfani da ra'ayoyi na musamman da haɓaka juzu'i don ƙarin cikakkun bayanai.

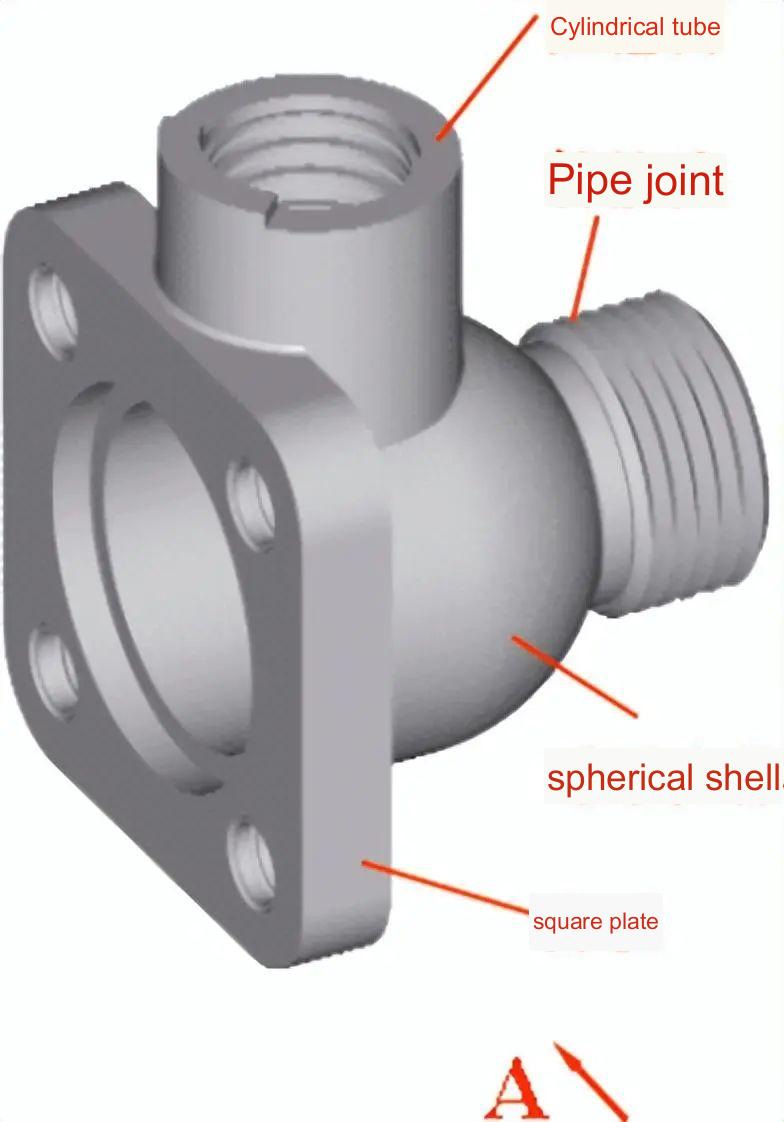

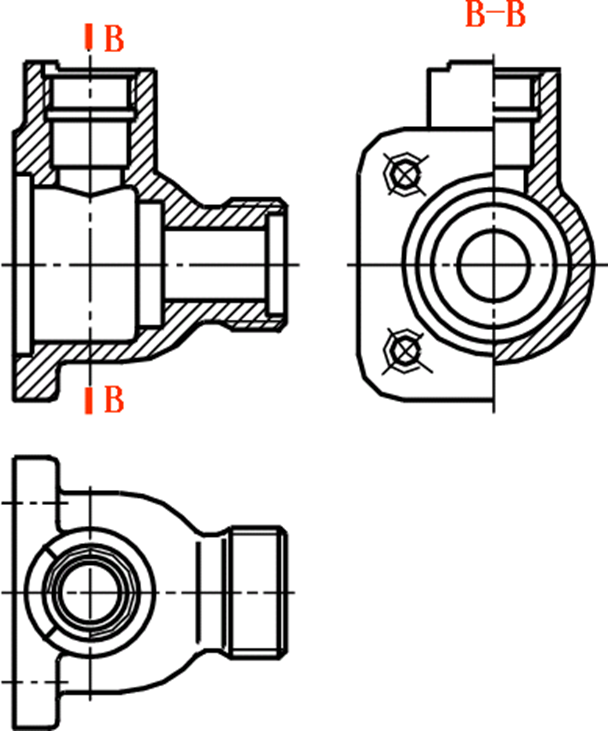

Hoto 3-10 Hanyar Magana na sassan jikin bawul

Hoto na 3-10 yana nuna jikin bawul.Ya ƙunshi sassa huɗu: bututu mai sassauƙa, farantin murabba'i, da haɗin bututu.An haɗa ramukan ciki na sassa masu zagaye da silinda ta hanyar haɗin kai tsakanin su biyun.Ana shirya kallon gaba na bawul bisa ga yanayin aiki na yanzu.Duban gaba yana da cikakken yanki don nuna siffar ciki na bawul, matsayi na dangi, da dai sauransu.

Zaɓi ra'ayi na rabin ɓangaren hagu don nuna bayyanar babban jikin bawul, siffar da girman farantin murabba'i a gefen hagu na bawul da tsarin rami na ciki.Zaɓi kallon sama don nuna gaba ɗaya siffa da tsarin saman bawul mai siffar fan.

Anebon suna da mafi yawan kayan aikin samarwa, ƙwararrun injiniyoyi da ƙwararrun injiniyoyi da ma'aikata, ingantaccen tsarin kula da inganci da ƙungiyar tallan tallan abokantaka kafin / bayan tallace-tallace don China wholesale OEM Plastic ABS / PA / POM CNC Lathe CNC Milling 4 Axis / 5 Axis CNC machining sassa,CNC juya sassa.A halin yanzu, Anebon yana neman gaba don haɓaka haɗin gwiwa tare da abokan cinikin waje bisa ga ribar juna.Da fatan za a fuskanci kyauta don tuntuɓar mu don ƙarin bayani.

2022 Babban ingancin Sin CNC da Machining, Tare da ƙungiyar ƙwararrun ma'aikata da ƙwararrun ma'aikata, Kasuwar Anebon ta rufe Kudancin Amurka, Amurka, Gabas ta Tsakiya, da Arewacin Afirka.Yawancin abokan ciniki sun zama abokan Anebon bayan kyakkyawar haɗin gwiwa tare da Anebon.Idan kuna da buƙatun kowane samfuranmu, ku tuna tuntuɓar mu yanzu.Anebon zai sa ido a ji daga gare ku nan ba da jimawa ba.

Lokacin aikawa: Satumba-12-2023