Koj paub ntau npaum li cas txog kev tsim kho tshuab?

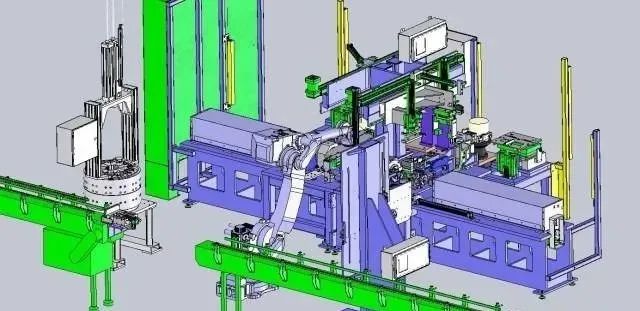

Nws suav nrog kev tsim, tshuaj xyuas thiab ua kom zoo rau ntau yam khoom siv tshuab kom tau raws li qhov xav tau tshwj xeeb thiab cov kev xav tau.Nws suav nrog kev tsim, tshuaj xyuas, thiab ua kom zoo rau ntau yam khoom siv kho tshuab kom ua tau raws li qhov xav tau tshwj xeeb thiab cov kev xav tau.Mechanical tsim muaj peev xwm suav nrog ntau qhov chaw, suav nrog cov khoom tsim, tshuab tsim, khoom tsim, thiab kev tsim qauv.Kev nkag siab thiab siv cov hauv paus ntsiab lus engineering xws li thermodynamics thiab cov ntaub ntawv tshawb fawb yog xav tau.

Kev tsim kho tshuab yog ib feem ntawm kev tsim, tsim khoom, siv thiab tu cov txheej txheem.Kev tsis saib xyuas hauv kev tsim qauv yuav ib txwm muaj kev cuam tshuam txog cov yam no.Nws tsis yog qhov nyuaj los txiav txim siab seb qhov project yuav ua tiav lossis ua tsis tiav.Kev tsim khoom muaj kev cuam tshuam zoo rau cov txheej txheem tsim, yog li kev tsim qauv zoo tsis yog cais los ntawm kev tsim khoom.Kev nkag siab txog kev tsim khoom yuav pab koj txhim kho koj cov txuj ci tsim qauv.

Kev tsim kho tshuab feem ntau cuam tshuam nrog kev tsim kom muaj kev ntseeg siab, raug nqi, thiab kev daws teeb meem zoo.Cov neeg tsim qauv feem ntau siv computer-aided design (CAD) software thiab cov cuab yeej los tsim cov qauv kom ntxaws, simulations, thiab ntsuas kev ua tau zoo ua ntej kev tsim khoom.Thiab cov txheej txheem tsim, cov neeg tsim khoom xav txog yam xws li kev nyab xeeb, kev cia siab, kev tsim khoom, ergonomics, zoo nkauj, thiab ib puag ncig. cuam tshuam.Txhawm rau kom muaj kev sib koom ua ke thiab kev ua haujlwm zoo, lawv ua haujlwm nrog lwm yam kev qhuab qhia xws li civil, industrial, thiab hluav taws xob engineers.

Tsis muaj ntau tus neeg kuv tau pom leej twg tuaj yeem sib sau ua ke tam sim ntawd thiab ua cov duab kos tom qab lawv tau muab tso rau hauv ntau lawm.Thaum lub sij hawm kev tshuaj xyuas kev kos duab thiab cov txheej txheem tom ntej, nws tsis yog ib qho uas yuav pom ntau yam teeb meem.Qhov no suav nrog cov duab kos uas tsim los ntawm lub npe hu ua senior engineers lossis Chief engineers.Qhov no yog qhov tshwm sim tom qab rov sib tham thiab ntau lub rooj sib tham.Qhov no yog vim muaj ntau yam.Ntawm ib sab tes muaj standardization nyob rau hauv daim duab, thiab theem ntawm tus saib.Tab sis qhov tsis to taub los ntawm tus tsim qauv ntawm cov txheej txheem tsim khoom ntawm qhov tod tes yog qhov laj thawj tseem ceeb.

Koj txiav txim siab npaum li cas koj paub txog kev tsim khoom?

Xaiv ib daim duab uas koj tau tsim.Dab tsi yog tag nrho cov txheej txheem tsim khoom?Nws yog tsis yooj yim sua los ua casting, forging thiab tig.Milling, npaj thiab sib tsoo kuj tsis tuaj yeem ua tau.Tus neeg twg uas tau ua haujlwm ntau xyoo hauv lub khw muag khoom paub qhov no.Yuav kom nkag siab txog cov txheej txheem, nws yuav tsum tau tawg ua cov kauj ruam me.Cov qauv ntawm ib feem yuav ua rau muaj kev sib tsoo thaum kho cua sov.Nws yog ib qho tseem ceeb kom paub yuav ua li cas kho nws thiab txiav cov khoom siv li cas.Virtualization yog siv los simulate cov txheej txheem, uas suav nrog cov riam, kev sib hloov ceev, cov cuab yeej pub tus nqi, txawm tias cov kev taw qhia ntawm cov hlau chips raug pov tseg, kev txiav txim ntawm kev siv riam, thiab kev ua haujlwm ntawm lub tshuab dhos.Peb tuaj yeem hais tias tam sim no peb muaj lub hauv paus muaj zog dua.

Cov ntsiab cai ntawm kev xaiv cov khoom siv rau cov khoom siv tshuab

yuav tsum xav txog peb yam ntawm cov cai

1. Cov kev cai siv (kev txiav txim siab tseem ceeb):

1) Cov kev ua haujlwm ntawm cov khoom (kev co, kev cuam tshuam, kev kub siab, tsis tshua muaj kub, siab ceev, thiab siab load yuav tsum tau kho nrog ceev faj);2) Kev txwv ntawm qhov loj thiab qhov zoo ntawm cov khoom;3) Qhov tseem ceeb ntawm cov khoom.(Qhov tseem ceeb ntawm kev ntseeg siab ntawm tag nrho lub tshuab)

2. Cov txheej txheem yuav tsum tau ua:

1) Kev tsim khoom dawb (casting, forging, phaj txiav, qws txiav);

2) Mechanical processing;

3) Kev kho cua sov;

4) Kev kho deg

3. Kev xav tau nyiaj txiag:

1) Cov khoom siv tus nqi (kev sib piv ntawm tus nqi dawb thiab cov nqi ua haujlwm ntawm cov hlau puag ncig zoo tib yam thiab txias-drawn profiles, precision casting, thiab precision forging);

2) Kev ua batch loj thiab cov nqi ua haujlwm;

3) Kev siv tus nqi ntawm cov ntaub ntawv;(xws li specifications ntawm daim hlau, tuav, thiab profiles, siv lawv tsim nyog)

4) Kev hloov pauv (sim siv cov ntaub ntawv pheej yig los hloov cov ntaub ntawv tsis tshua muaj nqi xws li cov ntawv luam tawm los hloov lub tes tsho tooj liab hauv qee qhov hnav-tiv taus qhov chaw lossis cov roj uas muaj cov bearings nyob rau hauv qhov chaw ntawm qee lub tes tsho tig thiab nylon nyob rau hauv cov ntaub ntawv uas tsis tshua muaj loads) Hloov steel iav nrog tooj liab cab iav thiab lwm yam.

Tsis tas li, xav txog qhov muaj cov khoom siv hauv zos

1. Cov kev cai yooj yim rau kev tsim kho tshuab

a) Ua tib zoo saib xyuas kev sib koom tes thiab sib npaug ntawm kev ua haujlwm ntawm lub tshuab!Tiv thaiv kom tsis txhob muaj qhov tshwm sim ntawm lub thoob

b) Cov kev xav tau ntawm kev lag luam tshuab: Tsim kev lag luam, tau txais nws mus rau hauv kev tsim khoom sai, rov qab noj thaum lub sij hawm tsim, thiab txawm tsim-tsim tib lub sijhawm rau kev lag luam.Qhov no yuav muab koj tus nqi zoo tshaj plaws / kev ua tau zoo (cov khoom pib hauv cov khoom me me).

2. Cov kev cai yooj yim rau kev tsim cov khoom siv tshuab

a) Ua haujlwm ib txwm thiab ntseeg tau nyob rau hauv lub sijhawm ua haujlwm tau teem tseg kom ntseeg tau ntau yam haujlwm ntawm lub tshuab;

b) Txo cov nqi tsim khoom thiab tsim khoom ntawm cov khoom;

c) Siv ntau yam qauv hauv kev ua lag luam raws li qhov ua tau;

d) Thaum tsim cov khoom lag luam uas tuaj yeem ua tiav, xav txog cov khoom siv ntau yam.Cov qauv ntawm cov uas tsis yog universal yuav tsum zoo ib yam li qhov siab tshaj plaws ua tau kom txo tau qhov nyuaj ntawm cov txheej txheem tsim khoom, thiab lub sij hawm tsim nyog rau fixture thiab tooling designs.

Saib kev xaiv ntawm ib feem ntawm cov khoom siv kos duab

Cov qauv zoo ntawm ib feem yog qhov tseem ceeb hauv kev txiav txim siab cov qauv qhia rau qhov pom.Cov khoom uas muaj cov duab zoo sib xws qhia cov yam ntxwv zoo sib xws.

Feem ntau, cov khoom siv tshuab tuaj yeem muab faib ua pawg raws li lawv cov duab, xws li bushings thiab log discs.Ntawm no yog lawv cov yam ntxwv qhia nyob rau hauv ntau txoj kev:

(1) Xaiv cov ncej thiab lub tes tsho

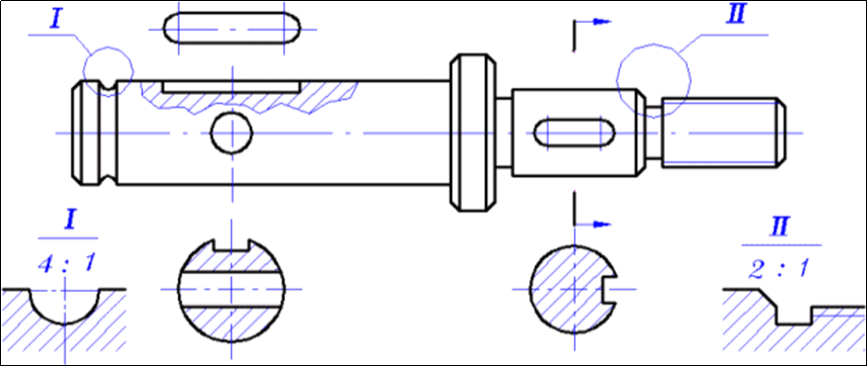

Lub axis ntawm lub shafts los yog lub tes tsho ib feem yog horizontally positioned raws li nws txoj hauj lwm ua.Nyob rau hauv dav dav, ib qho yooj yim thiab cross-sectional views, nrog rau ib nrab enlarged version, yog txhua yam uas xav tau.

(2) Tshawb xyuas peb cov kev xaiv ntawm lub log thiab disk qhov chaw

Nyob rau hauv lub ntsiab saib, lub axis kuj horizontally positioned raws li txoj hauj lwm ntawm kev ua.Qhov no yuav tsum muaj ob qhov kev pom yooj yim.

(3) Fork thiab Rod Parts

Forks thiab rods, piv txwv li, feem ntau nkhaus thiab qaij.Qhov kev pom zoo tshaj plaws sawv cev rau lawv cov yam ntxwv zoo yuav raug siv los ua cov duab tseem ceeb.Ob lossis ntau dua cov duab yooj yim kuj yuav tsum tau.

(4) Lub thawv qhov chaw xaiv

Box-hom Cheebtsam yog complex.Qhov chaw saib lub ntsiab yuav tsum sib haum mus rau qhov chaw ua haujlwm ntawm qhov chaw ntawm lub tshuab.Feem ntau, tsawg kawg yog peb qhov kev pom yooj yim xav tau.

Muaj ntau ntau yam kev qhia sib txawv rau ib feem.Txhua tus muaj nws cov txiaj ntsig thiab qhov tsis zoo thiab yuav tsum tau muab piv thiab txheeb xyuas kom meej.

Thaum xaiv views, nws yog ib qho tseem ceeb uas txhua qhov kev pom muaj qhov sib txawv.Cov kev xaiv xaiv yuav tsum ua kom tiav thiab meej, thiab nyeem tau yooj yim.

Ncej thiab lub tes tsho qhov chaw

Lub hom phiaj tseem ceeb ntawm cov ncej thiab lub tes tsho yog xa tawm lub zog, lossis txhawb nqa lwm qhov xws li cov ncej.

(1) Cov yam ntxwv ntawm cov qauv thiab cov txheej txheem ua rau cov ncej thiab lub tes tsho

Cov khoom tseem ceeb ntawm cov rotating lub cev yog lub tog raj kheej, cones thiab lwm yam rotating lub cev ntawm ntau qhov ntau thiab tsawg.Feem ntau ntawm cov ncej thiab lub tes tsho yog ua tiav siv cov lathes lossis grinders.Cov noauto spare qhov chawfeem ntau yog tsim, ua tiav los yog sib dhos nrog cov qauv zoo li chamfers thiab threads.Lawv kuj yuav muaj undercuts, pinholes, keyways los yog tiaj tus.

(2) Saib kev xaiv

Cov ncej thiab lub tes tsho yog sawv cev nrog lub ntsej muag pom, lub axis horizontally tso.Qhov no yog ua raws li tus lej tsim nyog lossis ntu ntu thiab nthuav dav ib feem.Kab rov tav txoj hauj lwm ntawm lub ntsiab saib yog zoo ib yam tsis tau tsuas yog nrog feature feature rau ib feem saib xaiv tab sis kuj nrog nws txoj hauj lwm ua thiab ua hauj lwm txoj hauj lwm.

Ib feem tuaj yeem siv los sawv cev rau cov qauv xws li lub qhov thiab lub qhov hauv cov ncej.Raws li pom nyob rau hauv daim duab 3-7, txoj hauv kev tseem ceeb, qhov thiab cov qauv dav hlau, ntawm lwm cov qauv, yuav tsum tau sawv cev raws li qhov sib txawv ntawm qhov sib txawv.

Khoom shafts tsis tas yuav tsum tau txiav, tab sis lub tes tsho Cheebtsam yuav tsum tau qhia lawv cov qauv sab hauv.Tag nrho seem saib tuaj yeem siv tau yog tias daim ntawv sab nraud yooj yim;ib nrab seem views yuav siv tau yog hais tias nws yog complex.

Daim duab 3-7 Axis qhia txoj kev

Pan thiab npog qhov chaw

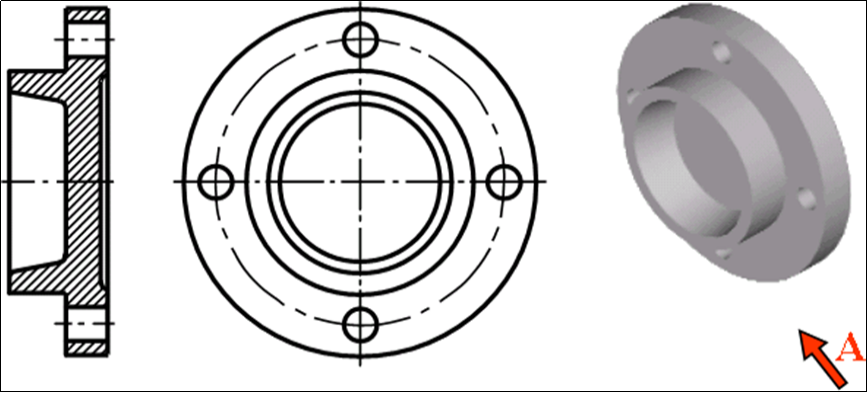

Muaj nyob rau hauv disc thiab npog qhov chaw yog kawg npog, flanges (handwheels), pulleys, thiab lwm yam tiaj tus disc-shaped Cheebtsam.Cov log yog siv los xa lub zog thiab npog feem ntau yog kev txhawb nqa, txoj haujlwm axial, thiab sealing.

1. Cov yam ntxwv zoo

Lub cev tseem ceeb ntawm lub disk lossis npog feem ntau yog lub cev coaxial tig.Qee lub cev muaj lub cev tseem ceeb uas yog square, duab plaub, lossis lwm cov duab, nrog cov radial loj dua thiab me me axial ntsuas.Raws li pom nyob rau hauv daim duab 3-8, qhov feem ntau muaj cov qauv zoo li lub qhov taub, qhov nyob ntawm qhov ncig ntawm qhov, tav los yog zawj, thiab cov hniav.

Daim duab 3-8 Kev nthuav qhia ntawm phaj / npog qhov chaw

(2) Saib kev xaiv

Feem ntau, disk thiab npog qhov chaw tuaj yeem nthuav tawm hauv ob qhov kev xav tau yooj yim.Lub ntsiab saib yog tag nrho cov hla ntu los ntawm axis.Lub axis yuav tsum tau horizontally positioned kom phim nws txoj hauj lwm ua.Lub ntsiab saib ntawm qee qhov chaw, uas tsis ua tiav feem ntau ntawm cov tshuab dhos tuaj yeem txiav txim siab raws li lawv cov duab thiab txoj haujlwm.

Ib qho yooj yim saib ntawm lub disk thiab lub hau npog yog ib txoj hauv kev los qhia txog kev faib cov qhov, zawj thiab lwm cov qauv nyob ib ncig ntawm lub disk lossis npog.Thaum qhov kev pom yog symmetrical, ib nrab-section saib yuav raug siv.

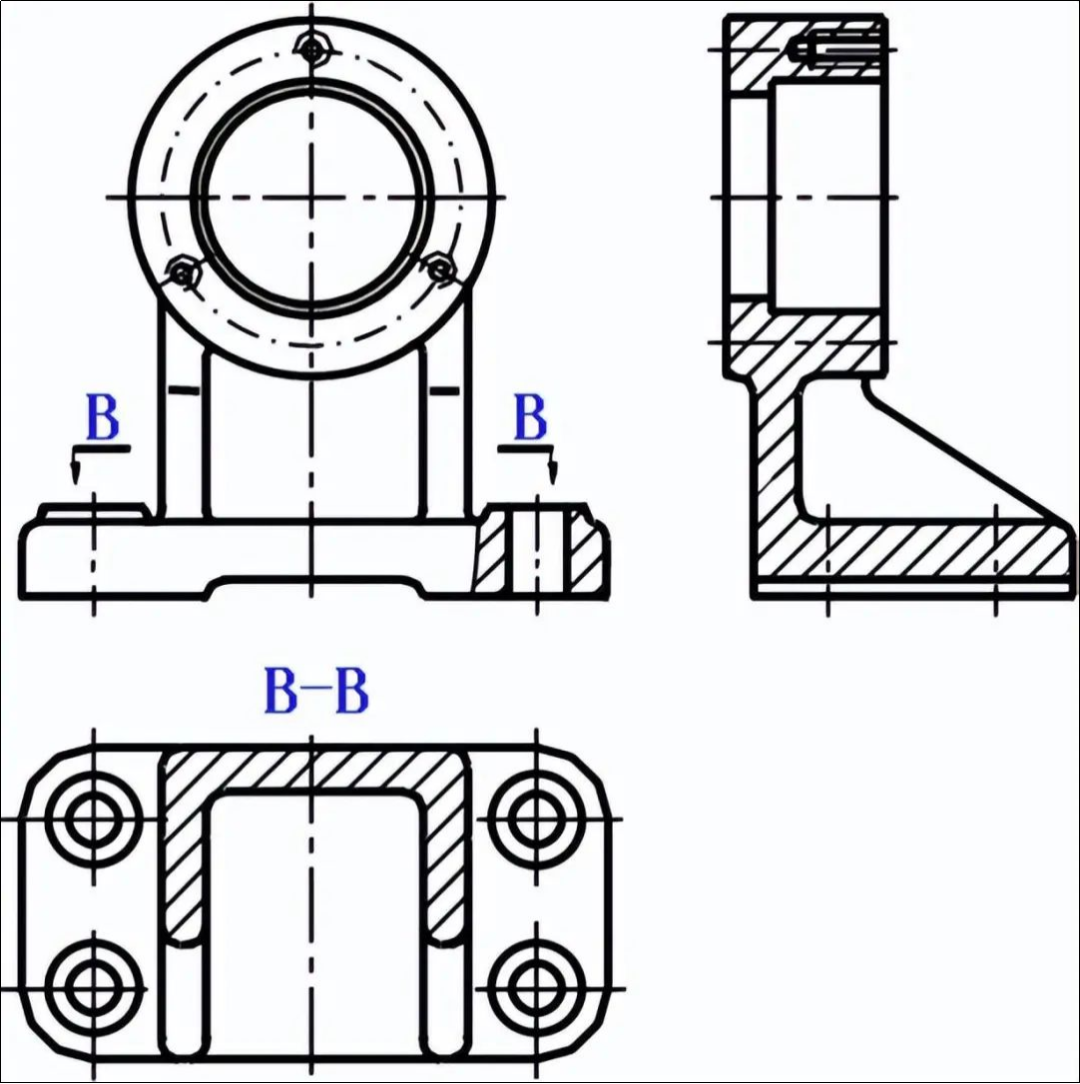

Forks thiab ncej qhov chaw

Cov ncej thiab rab rawg qhov chaw muaj xws li cov hlua txuas, cov hlua khi thiab lwm yam. Rau ntau lub hom phiaj.Hloov rab diav rawg thiab khi pas nrig ua lub luag haujlwm tseem ceeb hauv kev tswj lub tshuab.Brackets ua haujlwm zoo ib yam.Cov blanks no feem ntau yog cam khwb cia lossis forged.

(1) Cov yam ntxwv zoo

Feem ntau ntawm rab rawg thiab thav duab yog ua los ntawm peb qhov chaw: qhov chaw ua haujlwm, qhov nruab nrab, thiab qhov txuas.Kev ua haujlwm yog hais txog ib feem ntawm rab rawg lossis ncej uas muaj kev cuam tshuam rau lwm qhov chaw.Cov mounting qhov ntawm lub kaum sab xis hauv qab phaj ntawm bracket yog siv rau txoj hauj lwm thiab txuas lub bracket.Lub bracket txhawb nqa phaj txuas cov haujlwm ua haujlwm thiab kev teeb tsa.Thaum tsim cov khoom siv bracket, nws yog ib qho tsim nyog los tsim qhov chaw ua haujlwm thiab kev teeb tsa ntawm ntu ua ntej, tom qab ntawd ntxiv qhov txuas.

(2) Saib kev xaiv

Forks thiab thav duab yog feem ntau zoo li tus nyob rau hauv txoj kev complex, nrog nkhaus los yog tilted lug.Cov khoom tau raug rau ntau yam kev ua haujlwm sib txawv, thiab cov haujlwm ua haujlwm ntawm cov khoom no tsis raug kho.Feem ntau, qhov pom uas zoo tshaj plaws qhia txog cov yam ntxwv ntawm cov khoom raug xaiv los ua cov duab tseem ceeb.Lwm qhov kev pom, ib feem saib, ntu ntu, thiab lwm yam kev qhia, ntxiv rau cov kev xav tseem ceeb, raug xaiv raws li nws cov yam ntxwv.Raws li pom hauv daim duab 3-9.

Daim duab 3-9 Kev nthuav qhia txoj kev bracket qhov chaw

Lub thawv khoom

Cov khoom hauv lub thawv muaj xws li lub cev twj tso kua mis, lub cev lub cev, lub hauv paus tshuab, lub thawv txo, thiab lwm yam Castings yog siv los ua lub thawv qhov chaw, uas yog cov khoom tseem ceeb ntawm cov tshuab thiab cov khoom siv.Kev txhawb nqa, ntsaws ruaj ruaj, thiab txoj haujlwm feem ntau yog siv.

1. Cov yam ntxwv zoo

Lub thawv qauv sib txawv raws li qhov yuav tsum tau ua.Txawm li cas los xij, feem ntau yog cov plhaub hollow uas muaj cov kab noj hniav loj.Lub puab kab noj hniav sab hauv yog txiav txim siab los ntawm kev txav trajectory thiab cov duab ntawm lubmachined yammuaj nyob rau hauv lub thawv.Lub qhov bearing yog qhov uas txhawb nqa qhov txav ntawm lub thawv.Lub ntsej muag kawg ntawm lub qhov muaj cov qauv kev ua haujlwm hauv zos, xws li lub dav hlau los txhim kho lub hau kawg lossis lub qhov taub hau.

(2) Saib kev xaiv

Cov haujlwm ua haujlwm rau txhua qhov txheej txheem sib txawv.Cov khoom hauv lub thawv muaj cov qauv tsim thiab cov txheej txheem ua haujlwm nyuaj.Lub ntsiab saib feem ntau yog xaiv raws li txoj haujlwm ua haujlwm ntawm lub thawv thiab nws cov yam ntxwv zoo.Txhawm rau nthuav tawm cov duab puab sab hauv thiab sab nraud, nws yog ib qho tsim nyog yuav tsum muaj qhov txaus ntawm cov duab kos duab thiab cov duab kos duab.Cov kev pom tshwj xeeb thiab kev loj ib nrab tuaj yeem siv los ntxiv cov qauv kom ntxaws.

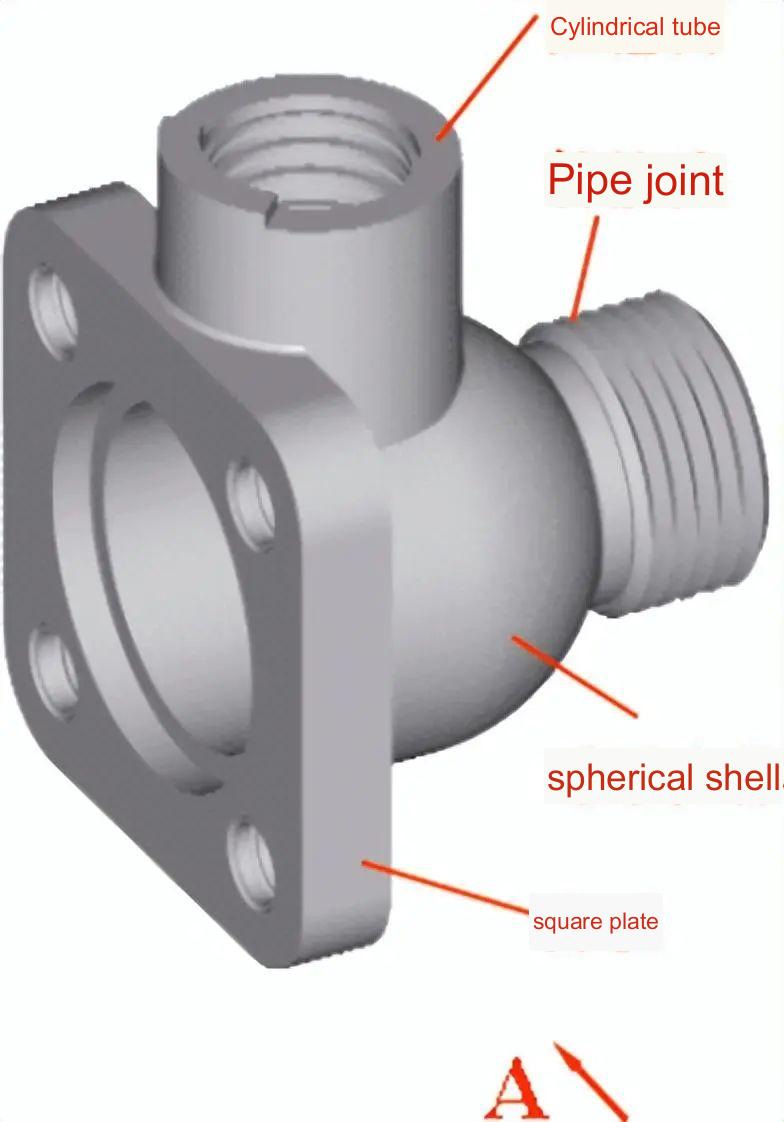

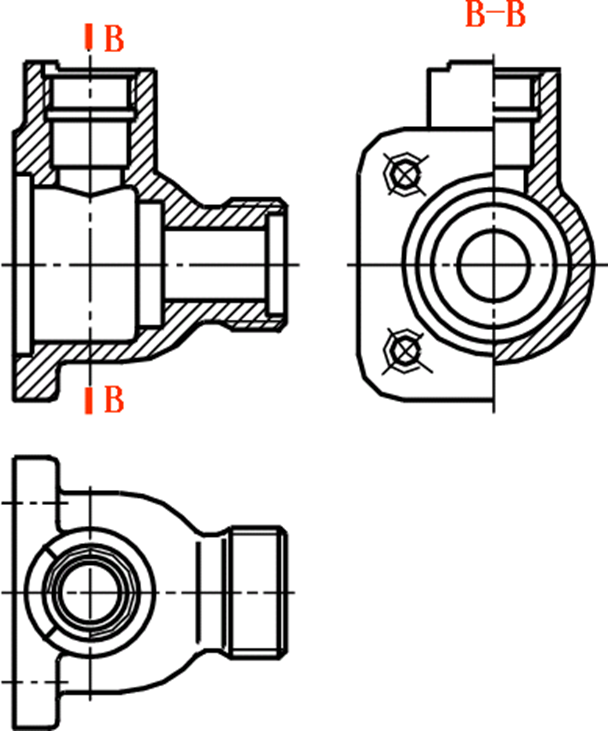

Daim duab 3-10 Kev nthuav qhia txoj kev ntawm lub cev lub cev

Daim duab 3-10 qhia txog lub cev valve.Nws muaj plaub ntu: ib lub raj kheej kheej, ib lub squareplate, thiab cov yeeb nkab txuas.Lub puab qhov ntawm lub puab kheej kheej thiab lub tog raj kheej yog txuas los ntawm kev sib tshuam ntawm ob.Lub hauv ntej saib ntawm lub valve yog npaj raws li nws qhov kev ua haujlwm tam sim no.Lub sab pem hauv ntej saib yog tag nrho sectioned los qhia lub puab puab ntawm lub valve, nws tus txheeb ze txoj hauj lwm, thiab lwm yam.

Xaiv qhov ib nrab-section saib sab laug los qhia qhov pom ntawm lub cev tseem ceeb ntawm lub valve, cov duab thiab qhov loj ntawm lub phaj square nyob rau sab laug ntawm lub valve thiab cov qauv hauv lub qhov.Xaiv lub sab saum toj-saib los qhia tag nrho cov duab thiab kiv cua-zoo li tus qauv sab saum toj ntawm lub valve.

Anebon muaj cov khoom siv ntau tshaj plaws, cov kws tshaj lij thiab cov kws tshaj lij thiab cov neeg ua haujlwm tsim nyog, lees paub cov kev tswj xyuas zoo thiab pab pawg muag khoom tus phooj ywg ua ntej / tom qab muag kev txhawb nqa rau Tuam Tshoj wholesale OEM Yas ABS / PA / POM CNC Tshuab dhos CNC Milling 4 Axis / 5 Axis CNC machining qhov chaw,CNC tig qhov chaw.Tam sim no, Anebon tab tom nrhiav ua ntej kom muaj kev koom tes loj dua nrog cov neeg siv khoom txawv teb chaws raws li kev sib koom ua ke.Thov koj xav paub dawb los tiv tauj peb kom paub meej ntxiv.

2022 Zoo siab Tuam Tshoj CNC thiab Machining, Nrog ib pab neeg ntawm cov neeg ua haujlwm paub txog thiab paub txog, Anebon lub lag luam npog South America, Tebchaws Asmeskas, Mid East, thiab North Africa.Ntau tus neeg muas zaub tau dhau los ua phooj ywg ntawm Anebon tom qab kev koom tes zoo nrog Anebon.Yog tias koj muaj qhov xav tau rau ib qho ntawm peb cov khoom, nco ntsoov tiv tauj peb tam sim no.Anebon yuav tos ntsoov hnov los ntawm koj sai sai no.

Post lub sij hawm: Sep-12-2023