Do you understand the application scope of geometric tolerance in CNC machining?

The specification of geometric tolerances is a crucial aspect of CNC machining, as it ensures accurate production of components. Geometric tolerances are the variations that can be made in the size, shape, orientation and location of a feature on a piece. These variations are crucial for the functional performance of the part.

Geometric tolerance is used in CNC machining for a variety of applications.

Dimensional control:

Geometric tolerences allow precise control of the size and dimension of machined features. It ensures that all parts are perfectly aligned and perform their intended function.

Form Control:

Geometric Tolerances ensure that the desired shape and contour is achieved for machined features. It is essential for parts which need to be assembled, or have specific mating requirements.

Orientation Control:

Geometric tolerences are used for the control of the angular alignment of features like holes, slots and surfaces. It is especially important for components which require accurate alignment or must fit precisely into other parts.

Geometric Tolerances:

Geometric tolerences are the deviations that can be made in the position of features on an item. It ensures that the critical features of a part are positioned accurately in relation to one another, enabling proper functionality and assembly.

Profile Control:

Geometric Tolerances are used to control overall shape and profile for complex features such as curves, contours and surfaces. This ensures that machined parts meet the profile requirements.

Control of Concentricity & Symmetry:

Geometric tolerances play a crucial role in achieving concentricity & symmetry for machined features. It is especially important when aligning rotating components like shafts, gears and bearings.

Runout control:

Geometric tolerances specify the allowed variation in the straightness and circularity of rotating cnc turned parts. It is designed to ensure smooth operation and reduce vibrations and errors.

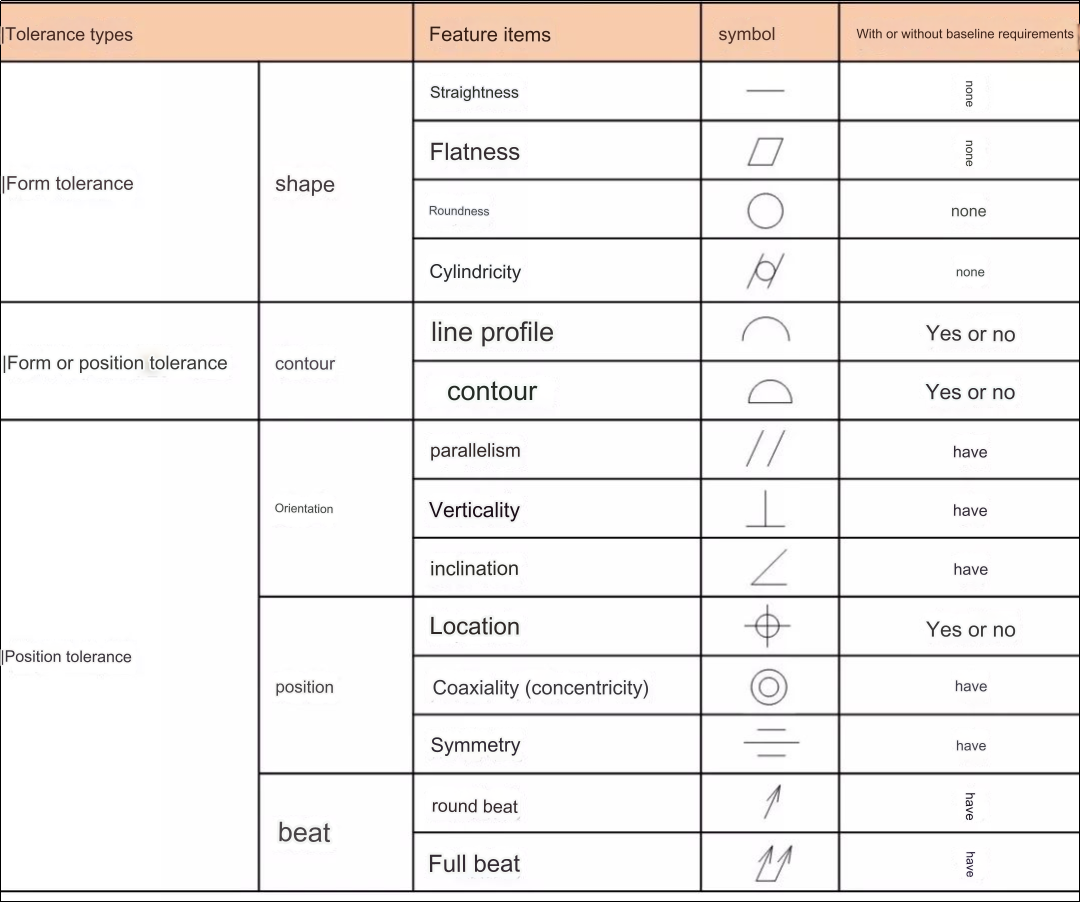

If we do not understand the geometric tolerances on the drawings in production, then the processing analysis will be off and the results of the processing may even be serious. This table contains a 14-item international standard geometric tolerance symbol.

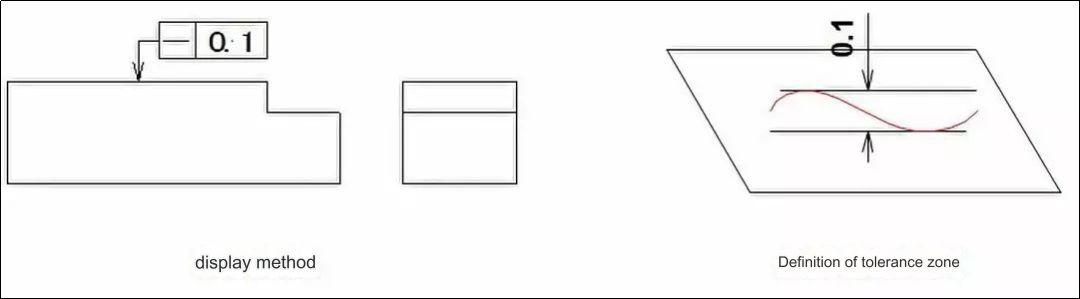

1. Straightness

Straightness is the ability of a part to maintain an ideal straightline. Straightness tolerance is defined as the maximum deviation of an actual straight line from an ideal line.

Example 1: The tolerance zone in a plane must be between two parallel straightlines with a distance 0.1mm.

Example 2: If you add the symbol Ph to the tolerance value then it must be in the area of a cylindrical surface that has a diameter 0.08mm.

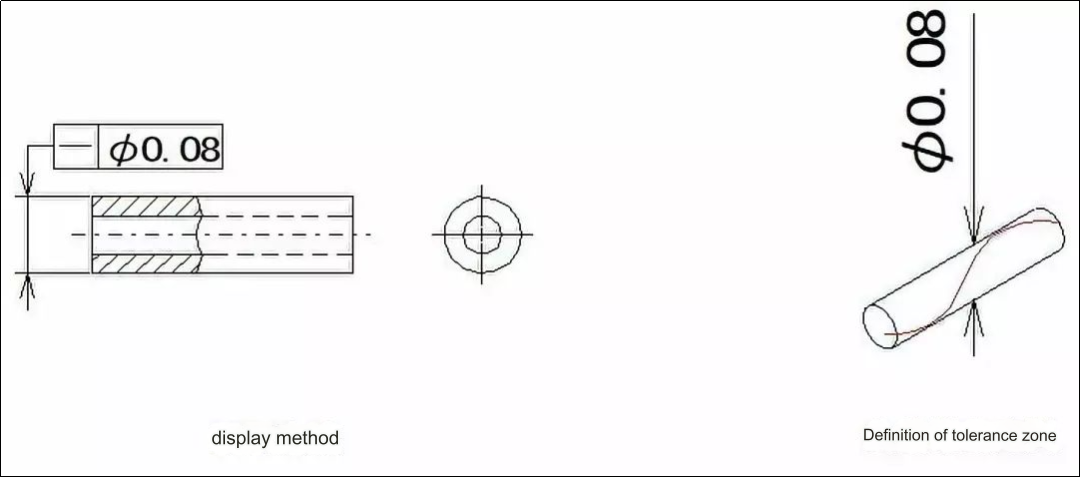

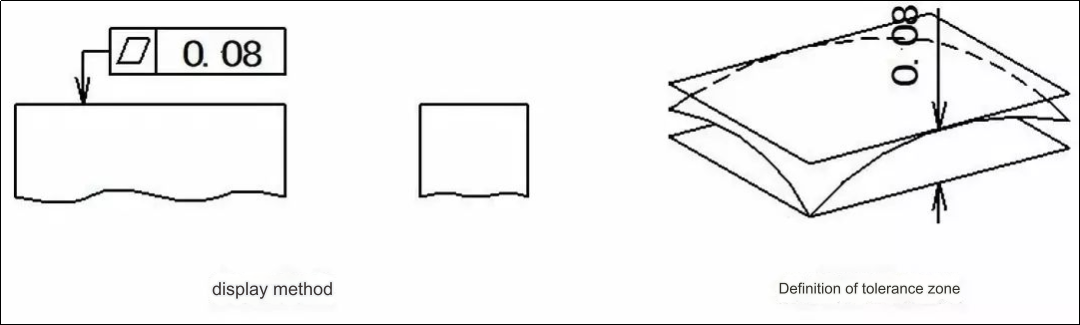

2. Flatness

Flatness (also known as flatness) is the condition in which a part maintains an ideal plane. Flatness tolerance is a measure of the maximum deviation that can be made between an ideal surface and an actual surface.

For example, the tolerance zone is defined as the space between parallel planes that are 0.08mm apart.

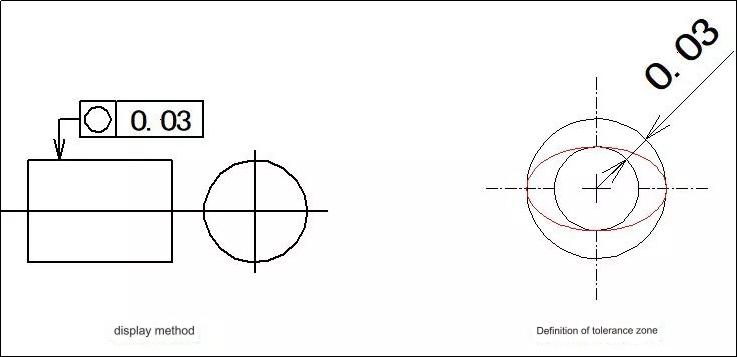

3. Roundness

The roundness of a component is the distance between the center and the actual shape. The roundness tolerance is defined as the maximum deviation of the actual circular shape from the ideal circular shape on the same cross section.

Example: Tolerance zone must be located on the same normal section. The radius difference is defined as the distance between two concentric rings with a tolerance of 0.03mm.

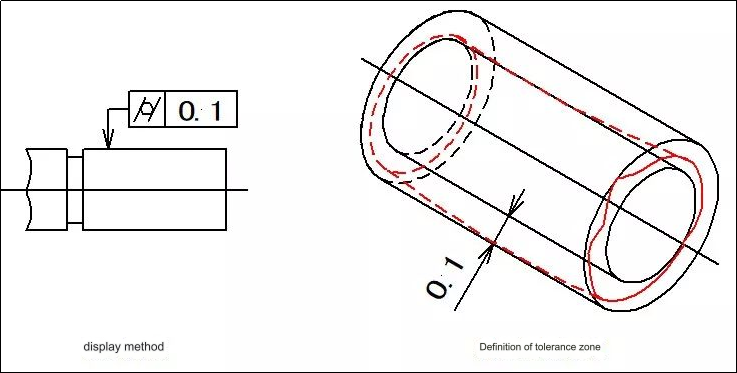

4. Cylindricity

The term ‘Cylindricity’ means that the points of the cylindrical surface of the part are all equally distant from its axis. The maximum allowed variation between an actual cylindrical surface and an ideal cylindrical is called the cylinderricity tolerance.

Example: Tolerance zone is defined as the area between coaxial cylindrical surfaces that have a difference in radius of 0.1mm.

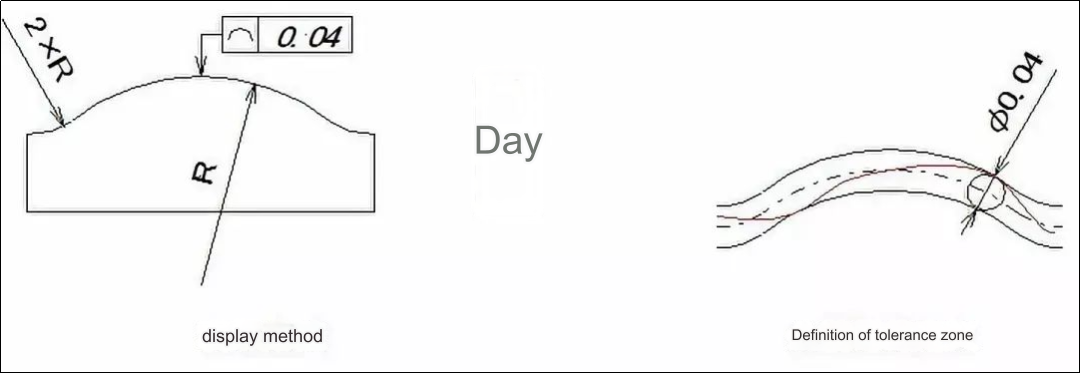

5. Line contour

Line profile is the condition where any curve, regardless of its shape, maintains the ideal shape in a particular plane of a part. Tolerance for line profile is the variation that can be made in the contour of non-circular curves.

For example, the tolerance zone is defined as the space between two envelopes that contains a series circles of diameter 0.04mm. The circles’ centers are on lines that have geometrically correct shapes.

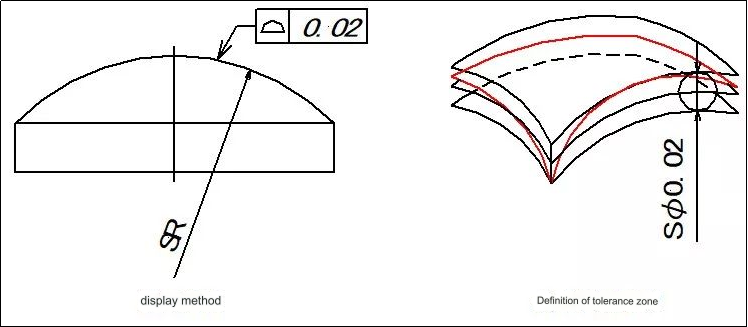

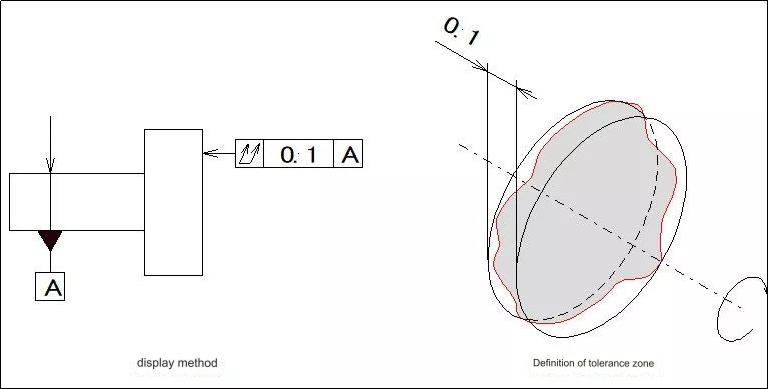

6. Surface contour

Surface contour is the condition where an arbitrary shaped surface on a component maintains its ideal form. Surface contour tolerance is the difference between the contour line and ideal contour surface of a noncircular surface.

For example: The tolerance zone lies between two envelopes lines that enclose a series balls with a 0.02mm diameter. The center of each ball should be on the surface of a geometrically correct shape.

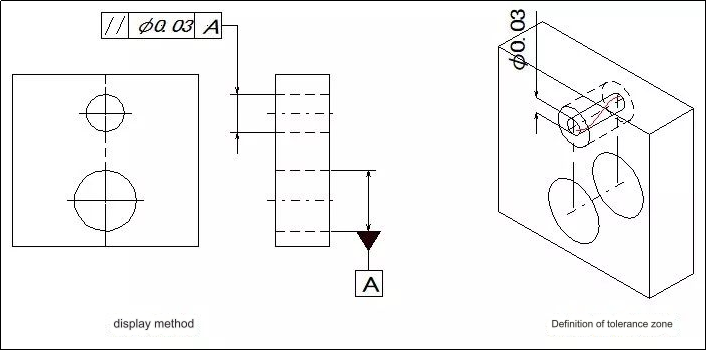

7. Parallelism

The degree of parallelism is a term used to describe the fact that the elements on a part are equidistant away from the datum. The parallelism tolerance is defined as the maximum variation that can be made between the direction in which the element being measured actually lies and the ideal direction, parallel to the datum.

Example: If you add the symbol Ph before the tolerance value then the tolerance zone will be within the cylinder surface with a reference diameter of Ph0.03mm.

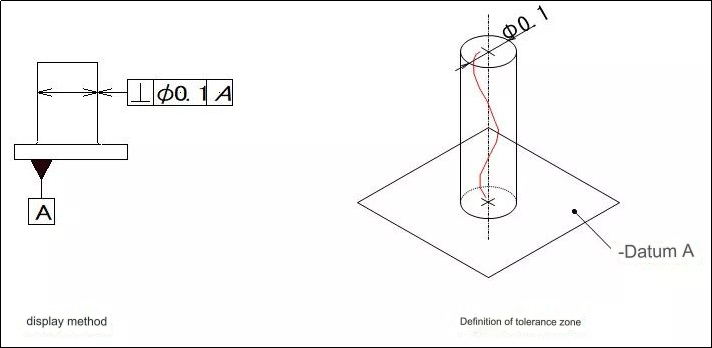

The degree of orthogonality, also known as perpendicularity between two elements indicates that the element measured on the part maintains the correct 90deg relative to the datum. Verticality tolerance is the maximum variation between the direction in which the feature is actually measured and that perpendicularly to the datum.

Example 1: The tolerance zone will be perpendicular with the cylindrical surface and a datum of 0.1mm if the mark Ph appears before it.

Example 2: Tolerance zone must be between two parallel planes, 0.08mm apart, and perpendicular the datum line.

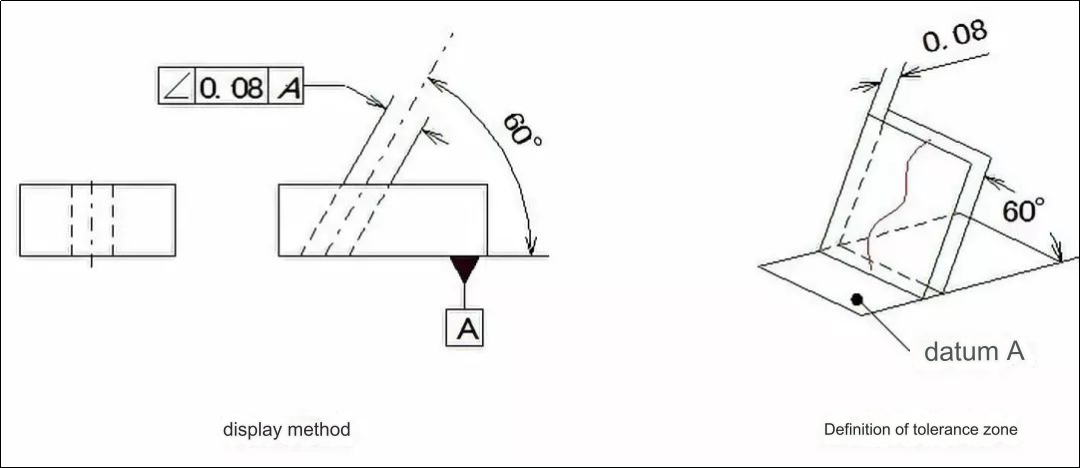

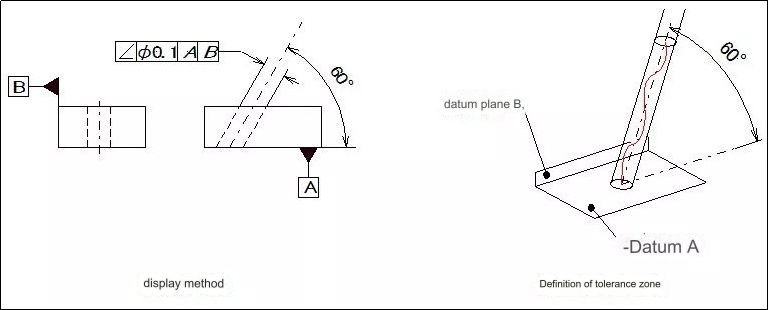

9. Inclination

Inclination is the condition that two elements must maintain a certain angle in their relative orientations. The slope tolerance is the amount of variation that can be allowed between the orientation of the feature to be measured and the ideal orientation, at any angle relative to the datum.

Example 1: Tolerance zone of the measured plane is the area between the two parallel planes that have a tolerance of 0.08mm, and an angle of theoretical 60deg to the datum plane.

Example 2: If you add the symbol Ph to the tolerance value then the zone of tolerance must be within a cylinder with a diameter 0.1mm. The tolerance zone must be parallel to plane A perpendicularly to datum B and at an angle of 60deg from datum A.

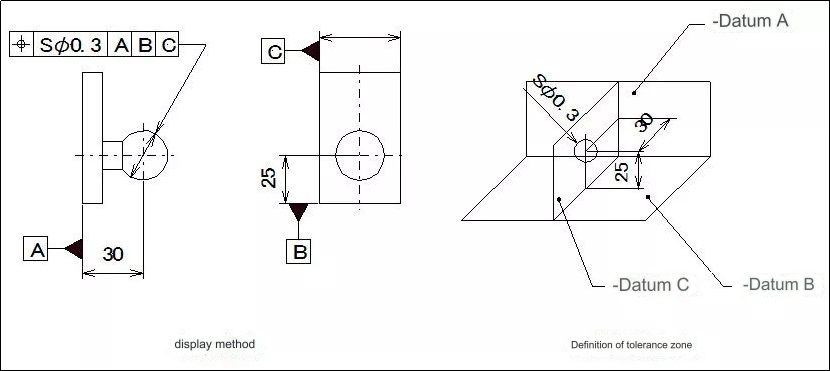

10. Location

Position is the precision of the points, surfaces, lines and other elements relative to their ideal position. Positional tolerance is defined as the maximum variation that can be allowed in the actual position relative to the ideal position.

As an example, when the SPh mark is added to the tolerance area, the tolerance is the inside of the ball that has a diameter 0.3mm. The center of the tolerance zone of the ball is the correct size in theory, relative to the datums of A, B and C.

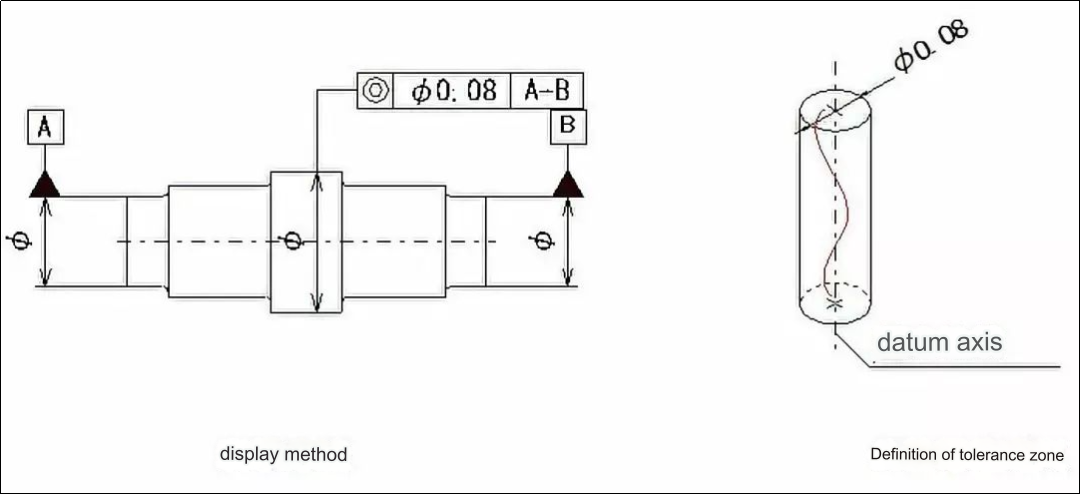

11. Coaxiality (concentricity).

Coaxiality is the term used to describe the fact that the measured axis of the part stays in the same straight-line relative to the reference axis. Tolerance for coaxiality is the variation that can be made between the actual axis and the reference axis.

For example: The tolerance zone, when marked with the tolerance value, is the space between two cylinders of diameter 0.08mm. The circular tolerance zone’s axis coincides with datum.

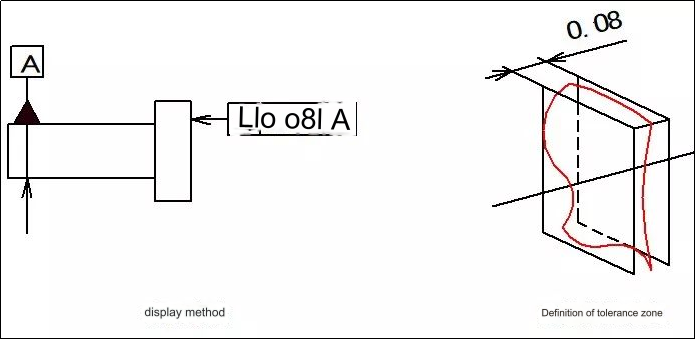

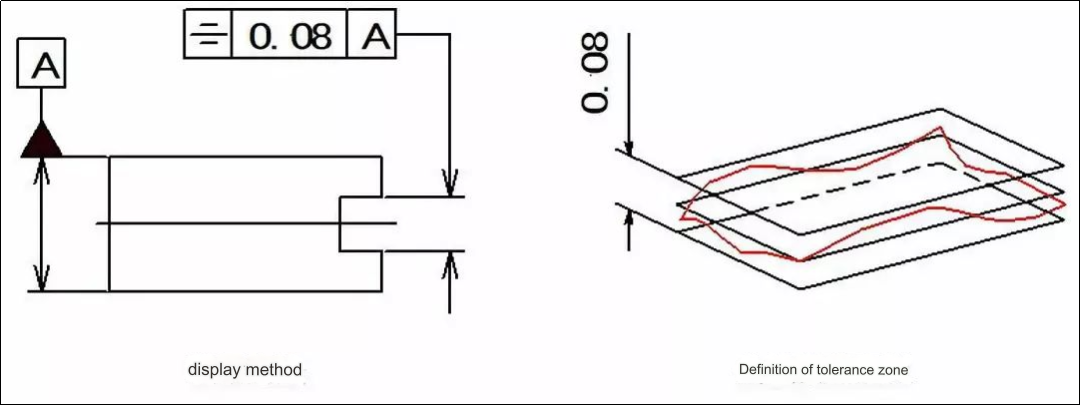

12. Symmetry

The symmetry tolerance is the maximum deviation of the symmetry center plane (or center line, axis) from the ideal symmetric plane. The symmetry tolerance is defined as the maximum deviation of the actual feature’s symmetry center plane, or center line (axis), from the ideal plane.

Example: Tolerance zone is the space between two parallel lines or planes that are 0.08mm from each other and are symmetrically aligned with the datum plane or centerline.

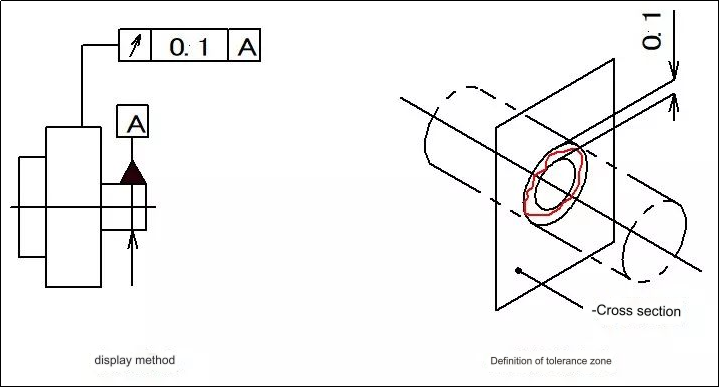

13. Circle Beat

The term circular runout refers to the fact that the surface of the revolution on the component remains fixed in relation to the datum plane within a restricted measurement plane. The maximum tolerance for circular runout is allowed in a restricted measurement range, when the element to be measured completes a full rotation around the reference axis without any axial movement.

Example 1: Tolerance zone is defined as the area between concentric circles with a difference in radius of 0.1mm and their centers located on the same datum plane.

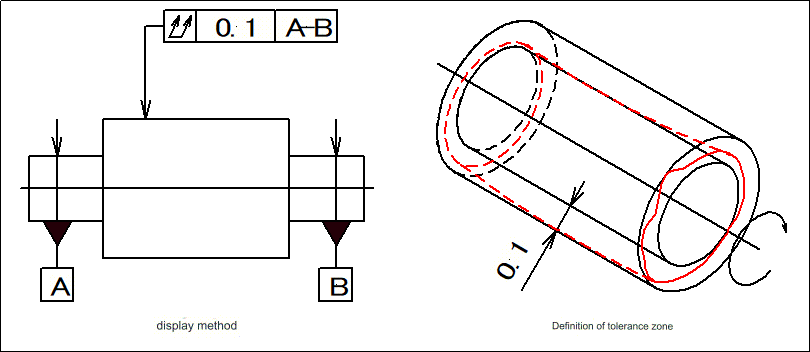

14. Full Beat

Total runout is the total runout on the surface of the measured part when it rotates continuously around the reference axis. Total runout tolerance is maximum runout when measuring the element while it rotates continuously around the datum axis.

Example 1: Tolerance zone is defined as the area between the two cylindrical surfaces that have a difference in radius of 0.1mm, and are coaxial to the datum.

Example 2: Tolerance zone is defined as the area between parallel planes that have a difference in radius of 0.1mm, perpendicular with the datum.

What impact does digital tolerance have on CNC machined parts?

Accuracy:

Digital tolerance assures that dimensions of machined components are within specified limits. It allows for parts to be produced that fit together correctly and function as intended.

Consistency:

Digital tolerance allows for consistency between multiple parts by controlling size and shape variations. This is especially important for parts which need to be interchangeable, or are used in processes such as assembly where uniformity is needed.

Fit and Assembly

Digital tolerance is used to ensure that parts can be assembled correctly and seamlessly. It prevents issues like interference, excessive clearances, misalignment and binding between parts.

Performance:

Digital tolerance is precise and allows parts to be produced that meet performance standards. Digital tolerance is crucial in industries such as aerospace and automotive where tight tolerances matter. It ensures that the parts are functionally optimal and meet strict quality standards.

Cost Optimization

Digital tolerance is important in finding the right balance between precision, cost and performance. By defining tolerences carefully, manufacturers can avoid excessive precision, which can increase costs while maintaining functionality and performance.

Quality Control:

Digital tolerance allows for rigorous quality control by providing specifications that are clear when measuring and inspecting machined components. It allows for the early detection of deviations from tolerances. This ensures consistent quality and timely corrections.

Design Flexibility

Designers have more flexibility when it comes to designing machined parts with digital tolerance. Designers can specify tolerances to determine acceptable limits and variations, while still ensuring the functionality and performance required.

Anebon can easily provide top quality solutions, competitive value and best client company. Anebon’s destination is “You come here with difficulty and we provide you a smile to take away” for Good Wholesale Vendors Precision Part CNC Machining Hard Chrome Plating Gear, Adhering to the small business principle of mutual advantages, now Anebon have won good reputation amid our buyers because of our best companies, quality goods and competitive price ranges. Anebon warmly welcome buyers from your home and overseas to cooperate with us for common results.

Good Wholesale Vendors China machined stainless steel, precision 5 axis machining part and cnc milling services. Anebon’s main objectives are to supply our customers worldwide with good quality, competitive price, satisfied delivery and excellent services. Customer satisfaction is our main goal. We welcome you to visit our showroom and office. Anebon have been looking forward to establish business relation with you.

If you want to know more, please contact info@anebon.com

Post time: Nov-17-2023