Mukudziwa chiyani za kukula kwamakina komwe kumafunikira kusamala?

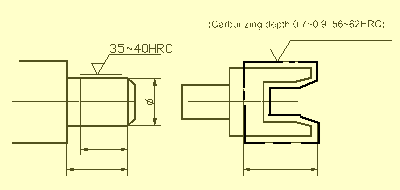

Makulidwe azinthu zonse:

Ndi miyeso yomwe imatanthawuza mawonekedwe onse ndi kukula kwa chinthu.Miyeso iyi nthawi zambiri imayimiridwa ngati manambala m'mabokosi amakona anayi osonyeza kutalika, m'lifupi ndi kutalika.

Kulekerera:

Kulekerera ndiko kusiyanasiyana kololedwa mumiyeso yomwe imatsimikizira kukwanira bwino, kugwira ntchito, ndi kusonkhana.Kulekerera kumatanthauzidwa ndi kuphatikiza kuphatikiza ndi kuchotsera zizindikiro pamodzi ndi manambala.Bowo lokhala ndi mainchesi a 10mm +- 0.05mm, mwachitsanzo, zikutanthauza kuti m'mimba mwake muli pakati pa 9.95mm mpaka 10.05mm.

Makulidwe a Geometric & Tolerances

GD&T imakupatsani mwayi wowongolera ndikutanthauzira geometry yazigawo ndi mawonekedwe agulu.Dongosololi limaphatikizapo mafelemu owongolera ndi zizindikiro kuti zitchule zinthu monga kusalala (kapena concentricity), perpendicularity (kapena parallelism), ndi zina zotero. Izi zimapereka zambiri zamawonekedwe ndi momwe zimakhalira kuposa miyeso yoyambira.

Pamwamba Pamwamba

Kutsirizitsa kwapamwamba kumagwiritsidwa ntchito kufotokoza momwe akufunira kapena kusalala kwa pamwamba.Mapeto a pamwamba amawonetsedwa pogwiritsa ntchito zizindikiro monga Ra (matanthauzo a masamu), Rz (mbiri yayitali kwambiri), ndi makulidwe ake enieni.

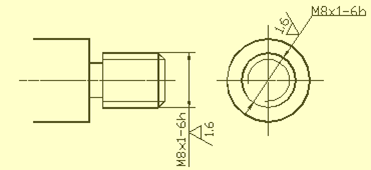

Mawonekedwe a Ulusi

Kuti muwonjezere zinthu za ulusi, monga ma bolts kapena zomangira, muyenera kufotokoza kukula kwa ulusi, phula ndi mndandanda wa ulusi.Mutha kuphatikizanso zina zilizonse, monga kutalika kwa ulusi, chamfers kapena kutalika kwa ulusi.

Mgwirizano wa Msonkhano & Kuchotsera

Tsatanetsatane wa dimensioning ndi wofunikiranso popanga magulu opangira makina kuti aganizire za mgwirizano pakati pa zigawo, komanso zovomerezeka zofunikira kuti zigwire bwino ntchito.Ndikofunikira kutchula malo okwerera, ma alignment, mipata ndi kulolerana kulikonse kofunikira kuti zigwire ntchito.

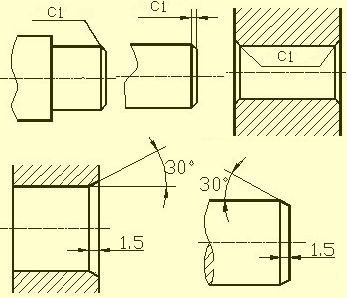

Njira zowongolerera zida zofananira

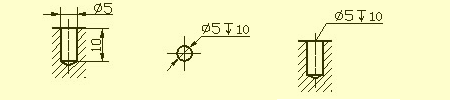

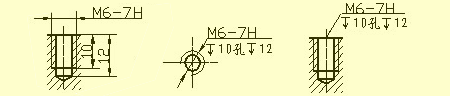

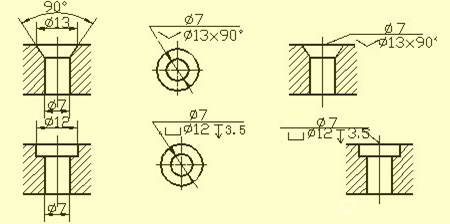

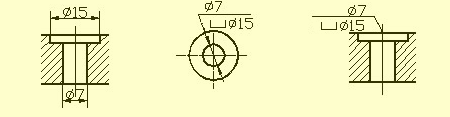

Njira zokulirapo za mabowo wamba (mabowo akhungu, mabowo a ulusi, mabowo osunthika, mabowo osunthika);njira za kukula kwa chamfers.

❖ Bowo lakhungu

❖ Bowo la ulusi

❖ Zoletsa

❖ Bowo lotsekera

❖ Chamfer

Zomangamanga pa mbali

❖ Mtsinje wa Undercut ndi grinding wheel overtravel poyambira

Kuwongolera kuchotsedwa kwa chida pagawo ndikuwonetsetsa kuti mawonekedwe a magawo omwe amalumikizana amakhala ofanana pamisonkhano, poyambira, poyambira, kapena poyambira mawilo opukutira, amayenera kugwiritsidwa ntchito pamtunda wamtunda. kukonzedwa.

Nthawi zambiri, kukula kwa njira yapansi panthaka kumatha kuwonetsedwa ngati "groove deep x diameter", kapena "groove deep x groove wide".The overtravel poyambira wa gudumu akupera pamene akupera mapeto a nkhope kapena kunja zozungulira.

❖Kubowola

Mabowo akhungu obowoledwa ndi 120deg pansi.Kuya kwa gawo la silinda ndikubowola kuya, osaphatikiza dzenje.Kusintha pakati pa dzenje lopondapo ndi chulu cha 120deg kumazindikiridwa ndi koni yokhala ndi njira yojambulira, komanso mawonekedwe.

Kuonetsetsa kubowola molondola, ndi kupewa kubowola biti kuthyoka, m'pofunika kuti axis pobowola kukhala perpendicular monga momwe angathere kumapeto pobowola.Chithunzi chili m'munsichi chikuwonetsa momwe mungapangire bwino nkhope zitatu zobowola.

❖Mabwana ndi ma dimples

Kawirikawiri, malo omwe amakhudzana ndi ziwalo zina kapena ziwalo zina amafunika kuthandizidwa.Mabwana ndi maenje pa castings nthawi zambiri amapangidwa kuti achepetse malo opangirako ndikuwonetsetsa kulumikizana kwabwino pakati pa malo.Mabwana apamwamba othandizira ndi maenje othandizira pamwamba amatsekedwa;kuchepetsa processing pamwamba, groove amapangidwa.

Common Part Structures

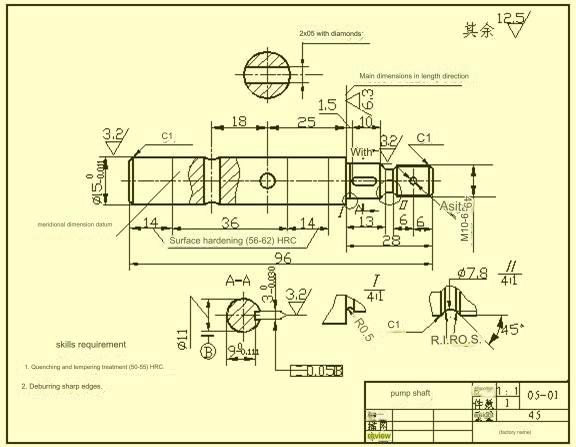

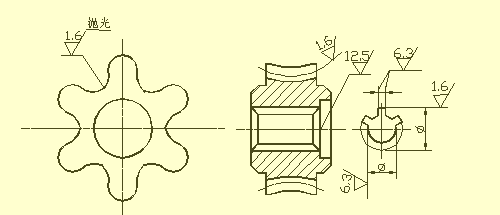

❖Zigawo za manja a shaft

Ma shafts, bushings, ndi mbali zina ndi zitsanzo za ziwalo zoterezi.Malingana ngati mawonedwe oyambira ndi magawo odutsa akuwonetsedwa, ndizotheka kufotokoza mawonekedwe ake am'deralo ndi mawonekedwe ake akuluakulu.Axis yowonetsera nthawi zambiri imayikidwa mopingasa kuti zikhale zosavuta kuwona zojambulazo.Mzere uyenera kuyikidwa pamzere woyima wambali.

Mzere wa bushing umagwiritsidwa ntchito kuyeza kukula kwa radial.Izi zimagwiritsidwa ntchito kudziwa F14, ndi F11 (onani Gawo AA), mwachitsanzo.Chithunzicho chikujambulidwa.Zofunikira pamapangidwe zimagwirizanitsidwa ndi benchmark ya ndondomeko.Mwachitsanzo, pokonza magawo a shaft pa lathe mutha kugwiritsa ntchito thimbles kukankhira dzenje lapakati la shaft.Kumbali yautali, mbali yofunika kwambiri yomaliza kapena yolumikizana (mapewa), kapena malo opangidwa ndi makina amatha kugwiritsidwa ntchito ngati chizindikiro.

Chithunzicho chikuwonetsa kuti phewa kumanja ndi roughness pamwamba Ra6.3, ndiye chofotokozera chachikulu cha miyeso yomwe imayang'ana kutalika.Ma size monga 13, 14, 1.5, ndi 26.5 akhoza kutengedwa kuchokera pamenepo.Chothandiziracho chimawonetsa kutalika kwa shaft yonse 96.

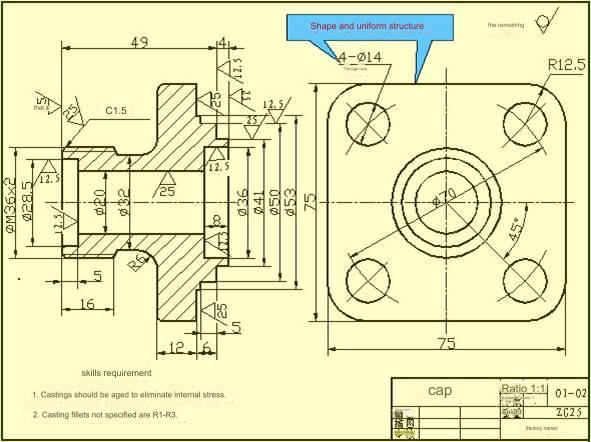

❖Zigawo za chivundikiro cha disk

Gawo lamtunduwu nthawi zambiri limakhala lathyathyathya.Zimaphatikizapo zophimba kumapeto, chivundikiro cha valve, magiya, ndi zina.Mapangidwe akuluakulu a zigawozi ndi thupi lozungulira lomwe lili ndi ma flange osiyanasiyana ndi mabowo ozungulira omwe amagawidwa mofanana.Zomanga m'deralo, monga nthiti.Monga lamulo, posankha mawonedwe muyenera kusankha mawonekedwe a chigawo pamodzi ndi axis kapena ndege ya symmetry monga lingaliro lanu lalikulu.Mukhozanso kuwonjezera mawonedwe ena pajambula (monga kumanzere, kumanja, kapena pamwamba) kuti muwonetse kufanana kwa mapangidwe ndi mawonekedwe.Pachithunzichi zikuwonetsedwa kuti mawonekedwe a kumanzere awonjezedwa kuti awonetse mawonekedwe a square flange, ndi ngodya zake zozungulira ndikugawidwa mofananamo anayi kupyolera mu mabowo.

Mukapanga miyeso ya zida zovundikira za diski, njira yoyendera kudutsa dzenje la shaft yomwe nthawi zambiri imasankhidwa ngati ma radial dimension axis ndipo m'mphepete yofunika kwambiri imasankhidwa ngati gawo loyambira lomwe limatsata kutalika kwake.

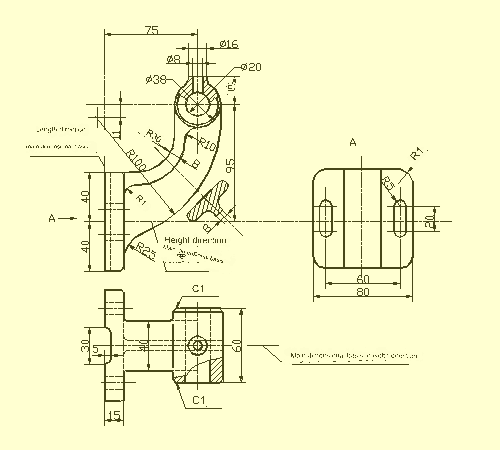

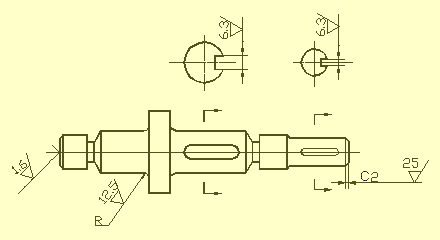

❖ Magawo a Foloko

Nthawi zambiri amakhala ndi ndodo zolumikizira ndi mafoloko osinthira, ndi zinthu zina zosiyanasiyana.Chifukwa cha malo awo osiyanasiyana opangira, malo ogwirira ntchito ndi mawonekedwe a gawolo amaganiziridwa posankha malingaliro omwe adzagwiritsidwe ntchito ngati oyambirira.Kusankhidwa kwa mawonedwe ena nthawi zambiri kumafunikira malingaliro awiri oyambira komanso magawo oyenera agawo, malingaliro ena pang'ono, ndi njira zina zofotokozera zomwe zimagwiritsidwa ntchito kuwonetsa momwe kapangidwe kake kamakhala komweko.Kusankhidwa kwa malingaliro omwe akuwonetsedwa m'magawo a chithunzi cha mpando wa pedal ndi osavuta komanso osavuta kumva.Pofuna kufotokoza kukula kwa nthiti ndi kukhala ndi maonekedwe abwino sikofunikira, koma kwa nthiti yomwe ili ndi mawonekedwe a T ndi bwino kugwiritsa ntchito gawolo.zoyenera.

Poyesa miyeso ya zigawo zamtundu wa foloko maziko a gawolo komanso ndondomeko yofananira ya chidutswacho nthawi zambiri amagwiritsidwa ntchito ngati malo owonetsera miyeso.Yang'anani chithunzichi cha njira zodziwira miyeso.

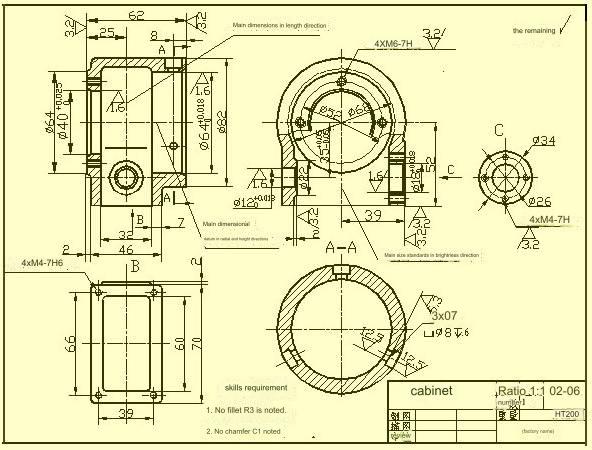

❖Magawo a bokosi

Nthawi zambiri, mawonekedwe ndi kapangidwe ka gawo ndizovuta kwambiri kuposa mitundu itatu ya magawo.Kuphatikiza apo, maudindo a processing amasintha.Nthawi zambiri amakhala ndi matupi a valve, mabokosi ochepetsera ma pampu, ndi zinthu zina zosiyanasiyana.Posankha mawonedwe a malingaliro aakulu, zodetsa nkhaŵa zazikulu ndizo malo a ntchito ndi zizindikiro za mawonekedwe.Ngati mukusankha malingaliro ena, malingaliro oyenerera othandizira zigawo zoterezi kapena malingaliro ochepa, magawo ndi malingaliro oblique ayenera kusankhidwa malinga ndi momwe zinthu zilili.Ayenera kufotokoza momveka bwino mawonekedwe akunja ndi amkati a chidutswacho.

Pankhani ya kukula, olamulira omwe amafunikira kugwiritsidwa ntchito popanga makiyi okwera pamwamba ndi malo olumikizirana (kapena malo opangira) komanso dongosolo lofananira (m'litali) la kapangidwe kake kabokosi, ndi zina zambiri zimagwiritsidwa ntchito. monga miyeso yolozera.Zikafika kumadera abokosi omwe amafunikira kudula miyeso iyenera kulembedwa ndendende momwe mungathere kuti muchepetse kuwongolera ndikuwunika.

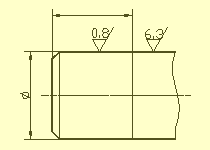

Pamwamba roughness

❖ Lingaliro la kukhwimitsa kwa pamwamba

Maonekedwe owoneka bwino a geometric okhala ndi nsonga ndi zigwa zomwe zili ndi mipata ing'onoting'ono padziko lonse lapansi zimadziwika kuti kuuma kwa pamwamba.Izi zimachitika chifukwa cha zikwapu zomwe zimasiyidwa ndi zida zomwe zili pamalopo popanga magawo, komanso kupindika komwe kumachitika chifukwa cha pulasitiki yapamtunda wachitsulo pakudula ndi kudula ndi kugawa.

Kuvuta kwa malo ndi chizindikiro cha sayansi chowunika momwe zigawozo zilili.Zimakhudza mawonekedwe a ziwalozo, kulondola kwake kofananira, kukana kukana dzimbiri, kusindikiza mawonekedwe ndi mawonekedwe.wa gawo.

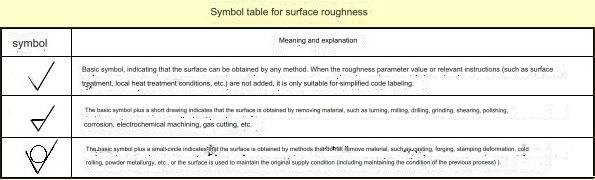

❖ Zizindikiro za makulidwe a pamwamba, zizindikiro ndi zizindikiro

Chikalata cha GB/T 131-393 chimafotokoza za makulidwe apamwamba komanso njira yake yolembera.Zizindikiro zomwe zimasonyeza kukhwimitsa zinthu za pamwamba pa zojambulazo zalembedwa pa tebulo ili pansipa.

❖ Zowunikira zazikulu za kuuma kwa malo

Magawo omwe amagwiritsidwa ntchito poyesa kuuma kwa gawolo ndi awa:

1.) Masamu amatanthauza kupatuka kwa contour (Ra)

Mtengo wa masamu wamtengo wapatali wa contour offset mu utali wake.Miyezo ya Ra komanso kutalika kwa zitsanzo zikuwonetsedwa mu tebulo ili.

2.) Kutalika kwakukulu kwa mbiri (Rz)

Kutalika kwa zitsanzo ndikuti ndi kusiyana pakati pa mizere ya pamwamba ndi pansi ya contour.

Zindikirani: Ra parameter imakondedwa mukamagwiritsa ntchito.

❖ Zofunikira pakulemba zaukali

1.) Chitsanzo cha zilembo zosonyeza kukhwima kwa pamwamba.

Miyezo yapamtunda ya Ra, Rz, ndi Ry imalembedwa ndi manambala mu code, pokhapokha ngati n'kotheka kusiya nambala ya parameter Ra sichifunika m'malo mwa mtengo woyenerera wa Rz kapena Ry iyenera kudziwika kale. pazigawo zilizonse.Onani Table chitsanzo cha momwe mungalembe.

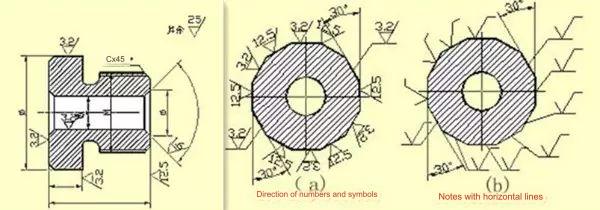

2.) Njira yolembera zizindikiro ndi manambala pamalo ovuta

❖ Kodi ndimayika bwanji kukhwimitsa kwa zilembo pazithunzi

1.) Kuvuta kwa pamwamba (chizindikiro) chiyenera kuikidwa ndi mizere yowonekera kapena mizere, kapena pamizere yawo yowonjezera.Mfundo ya chizindikirocho iyenera kuloza kuchokera kunja kwa zinthu ndi kumtunda.

2.) 2. Njira yeniyeni ya zizindikiro ndi manambala mu code ya roughness pamtunda iyenera kulembedwa motsatira malamulo.

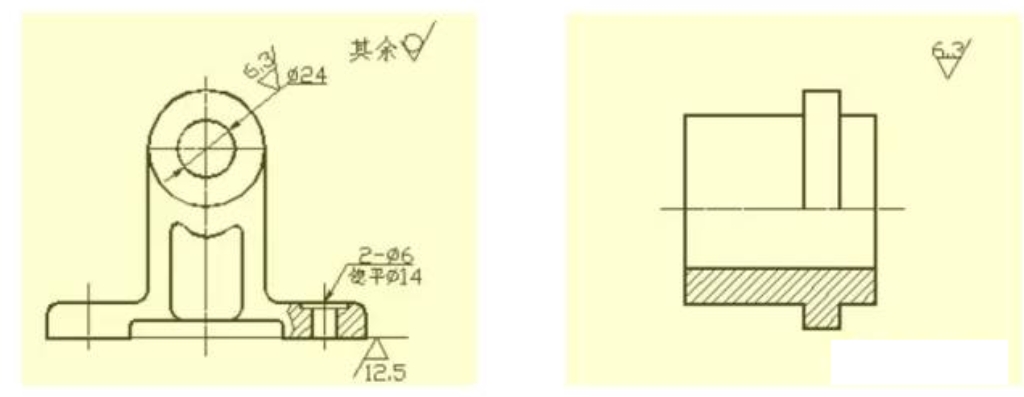

Chitsanzo chabwino chozindikiritsa makulidwe a pamwamba

Chojambula chomwecho chimagwiritsidwa ntchito pamtunda uliwonse nthawi zambiri chimalembedwa pogwiritsa ntchito mbadwo umodzi wokha (chizindikiro) komanso pafupi kwambiri ndi mzere wa dimension.Ngati malowo sali aakulu mokwanira kapena ndi ovuta kuwalemba, ndizotheka kujambula mzere.Pamene malo onse pa chinthu akwaniritsa zofunikira zomwezo kuti zikhale zolimba, zolembera zimatha kupangidwa mofanana kumtunda kumanja kwa chojambula chanu.Malo ambiri a chidutswa akamafanana ndi makulidwe a pamwamba, chizindikiro (chizindikiro) chomwe chimagwiritsidwa ntchito nthawi imodzi, lembani izi kumtunda kumanzere kwa chojambula chanu.Komanso, phatikizani "mpumulo" "mpumulo".Miyezo ya malo onse ozindikirika mofananamo chizindikiro chakukali (zizindikiro) ndi mawu ofotokozera ayenera kuwirikiza ka 1.4 kutalika kwa zolembera pachojambula.

The roughness pamwamba (chizindikiro) pa mosalekeza yokhota pamwamba pa chigawo chimodzi, pamwamba zinthu zimene mobwerezabwereza (monga mano, mabowo grooves, mabowo kapena grooves.) komanso discontinuous pamwamba ophatikizidwa ndi woonda olimba mizere okha. anaona kamodzi kokha.

Ngati pali zochulukira za kukhwimitsa kwa pamwamba kwa dera lomwelo mzere wopyapyala wolimba uyenera kujambulidwa kuti ulembe mzere wogawikanawo ndipo makulidwe oyenera ndi miyeso iyenera kulembedwa.

Zikatsimikizirika kuti dzino (dzino) silinatsatidwe pamwamba pa ulusi, magiya kapena magiya ena.Kukhwima kwa code pamwamba (chizindikiro) chikuwoneka mu fanizo.

Zizindikiro za roughness za ntchito pamwamba pa dzenje lapakati, mbali ya keyway fillets ndi chamfers akhoza kufewetsa ndondomeko kulemba.

Ngati ndicnc milled magawoziyenera kutenthedwa ndi kutentha kapena zokutidwa pang'ono (zokutidwa) malo onsewo ayenera kukhala ndi mizere yokhuthala ya mizere ya madontho, ndipo miyeso yogwirizana nayo iyenera kulembedwa bwino.Mafotokozedwewo amatha kuwoneka pamzere mopingasa m'mphepete mwakutali kwa chizindikiro chapamwamba.

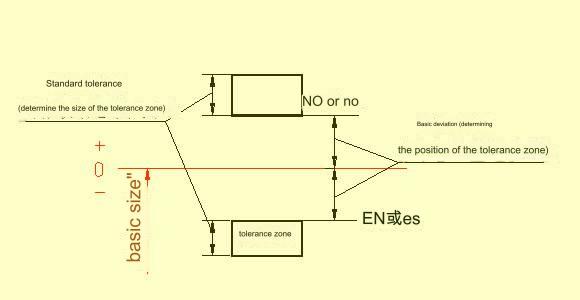

Basic tolerances ndi zopatuka muyezo

Kuti atsogolere kupanga kulola interoperability wacnc makina zigawondikukwaniritsa zofunikira zosiyanasiyana zogwiritsiridwa ntchito, muyezo wadziko lonse "Malire ndi Zokwanira" umanena kuti malo olekerera amakhala ndi zigawo ziwiri zomwe ndizololera zokhazikika komanso zopatuka.The kulolerana muyezo ndi chimene chimatsimikizira kukula kwa zone kulolerana ndi zone kupatuka kusankha dera la kulolerana zone.

1.) Kulekerera Kwambiri (IT)

Ubwino wa kulekerera kwa Standard udzatsimikiziridwa ndi kukula kwa maziko ndi kalasi.Gulu la kulolerana ndi muyeso womwe umatanthawuza kulondola kwa miyeso.Imagawidwa m'magawo 20, makamaka IT01, IT0 ndi IT1.,…, IT18.Kulondola kwa miyeso ya miyeso kumachepa mukamayenda kuchokera ku IT01 mpaka IT18.Kuti mumve zambiri za kulekerera kokhazikika, onani milingo yoyenera.

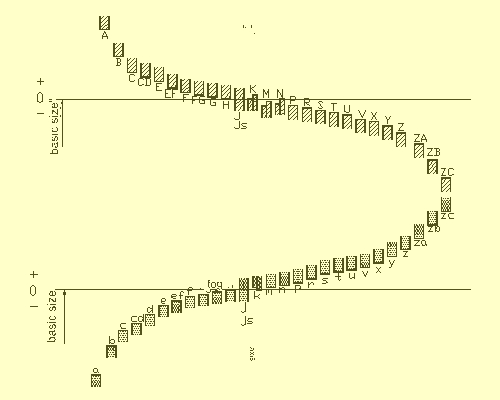

Kupatuka Kwambiri

Kupatuka koyambira ndikupatuka kumtunda kapena kutsika poyerekeza ndi ziro mu malire okhazikika, ndipo nthawi zambiri kumatanthauza kupatuka pafupi ndi ziro.Kupatuka koyambira kumakhala kotsika pamene malo olekerera ali apamwamba kuposa mzere wa zero;mwinamwake ndi chapamwamba.Mipatuko yoyambira 28 imalembedwa m'malembo achilatini okhala ndi zilembo zazikulu pamabowo ndi zilembo zing'onozing'ono kuyimira ma shafts.

Pachithunzi cha zopatuka zoyambira, zikuwonekeratu kuti bowo lopatuka AH ndi shaft yoyambira kupatuka kzc imayimira kupatuka kwapansi.Kupatuka koyambira kwa dzenje kwa KZC kumayimira kupatuka kwapamwamba.Kupatuka kumtunda ndi kumunsi kwa dzenje ndi kutsinde ndikotsatana + IT/2 ndi –IT/2.Chojambula choyambirira chopatuka sichiwonetsa kukula kwa kulolerana, koma malo ake okha.Kulekerera kokhazikika ndiko mbali ina ya kutsegula kumapeto kwa malo olekerera.

Malinga ndi tanthauzo la kulolerana kwa dimensional, njira yowerengera yapatuka koyambira ndi muyezo ndi:

EI = ES + IT

ei=es+IT kapena es=ei+IT

Khodi yololera pa dzenje ndi shaft imapangidwa ndi ma code awiri: khodi yoyambira yopatuka, ndi kalasi ya tolerance zone.

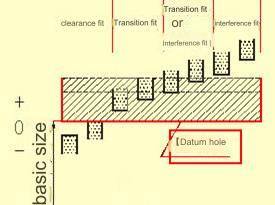

Gwirizanani

Fit ndi mgwirizano pakati pa malo olekerera mabowo ndi ma shaft omwe ali ndi gawo lofanana ndipo amaphatikizidwa pamodzi.Kukwanira pakati pa shaft ndi dzenje kumatha kukhala kolimba kapena kotayirira kutengera zomwe mukufuna.Chifukwa chake, mulingo wadziko umatchula mitundu yosiyanasiyana ya zoyenera:

1) Kukonzekera kokwanira

Bowo ndi shaft ziyenera kugwirizana ndi chilolezo chochepa cha ziro.Malo olekerera dzenje ndi apamwamba kuposa malo olekerera shaft.

2) Mgwirizano wapakati

Pakhoza kukhala mipata pakati pa tsinde ndi dzenje pamene asonkhanitsidwa.Malo olekerera dzenje amadutsana ndi shaft.

3) Kusokoneza koyenera

Posonkhanitsa shaft ndi dzenje, pali zosokoneza (kuphatikizapo kusokoneza kochepa kofanana ndi zero).Malo olekerera shaft ndi otsika kuposa malo olekerera dzenje.

❖ Dongosolo la benchmark

Popanga zamakina a cnc, gawo limasankhidwa ngati datum ndipo kupatuka kwake kumadziwika.Dongosolo la datum ndi njira yopezera mitundu yosiyanasiyana yofananira ndi zinthu zosiyanasiyana, posintha kupatuka kwa gawo lina lomwe silili datum.Miyezo ya dziko imatchula machitidwe awiri a benchmark kutengera zofunikira zenizeni zopangira.

1) Dongosolo lofunikira la dzenje likuwonetsedwa pansipa.

Basic hole system (yomwe imatchedwanso Basic hole System) ndi njira yomwe malo olekerera a dzenje ali ndi kupatuka kwina kuchokera ku muyezo ndi malo olekerera a shaft omwe ali ndi zopatuka mosiyanasiyana kuchokera ku mawonekedwe oyenera osiyanasiyana.Pansipa pali kufotokozera za dongosolo la dzenje loyambira.Onani chithunzi chomwe chili pansipa.

①Basic hole system

2) Dongosolo loyambira la shaft likuwonetsedwa pansipa.

Basic shaft system (BSS) - Iyi ndi njira yomwe madera olekerera shaft ndi dzenje, chilichonse chimakhala chosiyana, chimapanga zofananira zosiyanasiyana.Pansipa pali kufotokozera za dongosolo loyambira la axis.Datum axis ndi axis mu axis yoyambira.Khodi yake yopatuka (h) ndi h ndipo kupatuka kwake kumtunda ndi 0.

②Dongosolo loyambira la shaft

❖ Malamulo a mgwirizano

Fit code imapangidwa ndi ma tolerance zones code of the hole ndi shaft.Zalembedwa mu mawonekedwe a magawo.Khodi yololera ya dzenje ili mu nambala, pomwe code yololera ya shaft ili mu denominator.Axis yoyambira ndi kuphatikiza kulikonse komwe kumakhala ndi h ngati manambala.

❖ Kuzindikiritsa kulolerana ndi kukwanira pazithunzi

1) Gwiritsani ntchito njira yophatikizira yolembera kuti mulembe kulolerana ndikuyenererana ndi chojambula cha msonkhano.

2) Mitundu iwiri yolembapo imagwiritsidwa ntchitomakina opanga zigawozojambula.

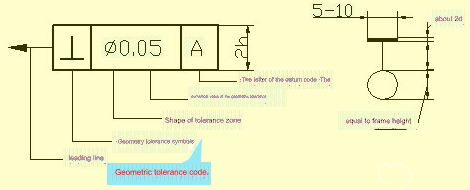

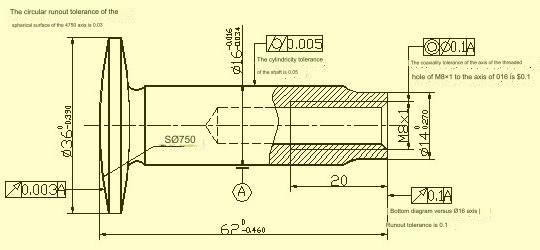

Kulekerera kwa geometric

Pali zolakwika za geometrical ndi zolakwika pazogwirizana mbali zitakonzedwa.Silinda ikhoza kukhala ndi kukula koyenerera koma kukhala yokulirapo kumapeto kwina kuposa ina, kapena yokulirapo pakati, pomwe imakhala yocheperako kumapeto kulikonse.Itha kukhalanso yozungulira pagawo lopingasa, chomwe ndi cholakwika cha mawonekedwe.Pambuyo pokonza, nkhwangwa za gawo lililonse zimatha kukhala zosiyana.Izi ndi zolakwika.Kulekerera kwa mawonekedwe ndiko kusiyana komwe kungapangidwe pakati pa mawonekedwe abwino ndi enieni.Kulekerera kwa malo ndiko kusiyana komwe kungapangidwe pakati pa malo enieni ndi abwino.Onsewa amadziwika kuti kulolerana kwa geometric.

Zipolopolo zokhala ndi Geometric Tolerance

❖ Zizindikiro zololera za mawonekedwe ndi maudindo

Muyezo wadziko lonse wa GB/T1182-1996 umatchula zizindikiro zogwiritsira ntchito kusonyeza mawonekedwe ndi kulolerana kwa malo.Pamene kulolerana kwa geometric sikungathe kuzindikirika ndi code mu kupanga kwenikweni, kufotokozera malemba kungagwiritsidwe ntchito.

Zizindikiro za kulekerera kwa geometric zimakhala ndi: mafelemu olekerera ma geometric, mizere yolondolera, kulekerera kwa geometric, ndi zizindikiro zina zofananira.Kukula kwa mafonti mu chimango kumakhala kutalika kofanana ndi mawonekedwe.

❖ Chizindikiro cha geometric tolerance

Zolemba pafupi ndi kulekerera kwa geometric zomwe zikuwonetsedwa pachithunzichi zikhoza kuwonjezeredwa kuti zifotokoze lingaliro kwa owerenga.Sichiyenera kuphatikizidwa muzojambula.

Anebon imanyadira kukwaniritsidwa kwamakasitomala komanso kuvomerezedwa kwakukulu chifukwa cha kulimbikira kwa Anebon kufunafuna zapamwamba pazogulitsa ndi ntchito za CE Certificate Customized High Quality Computer Components CNC Turned Parts Milling Metal, Anebon yakhala ikuthamangitsa WIN-WIN ndi ogula athu. .Anebon alandirirani mwachikondi makasitomala ochokera padziko lonse lapansi akubwera mopitilira kubwera kudzacheza ndikukhazikitsa ubale wachikondi wokhalitsa.

CE Certificate China cnc makina a aluminiyamu zigawo,CNC Inatembenuza Magawondi cnc lathe ziwalo.Ogwira ntchito onse mufakitale, sitolo, ndi ofesi ya Anebon akuvutika kuti akwaniritse cholinga chimodzi kuti apereke zabwino ndi ntchito zabwino.Bizinesi yeniyeni ndiyo kupeza mwayi wopambana.Tikufuna kupereka chithandizo chochulukirapo kwa makasitomala.Takulandilani ogula onse abwino kuti azilumikizana nafe tsatanetsatane wazogulitsa zathu ndi mayankho!

Ngati mukufuna kudziwa zambiri kapena mukufuna mawu, chonde lemberaniinfo@anebon.com

Nthawi yotumiza: Nov-29-2023