Yuav ua li cas dav npaum li cas qhov zoo-paub qhov tob machining system siv rau peb cov txheej txheem machining?

Phom phom thiab riam phom systems:

Kev sib sib zog nqus bore drilling ua lub luag haujlwm tseem ceeb hauv kev tsim cov phom phom, kom ntseeg tau qhov tseeb thiab qhov tseeb ntawm lub thoob qhov ntev, phom ntev, thiab qhov chaw zoo nkauj.

Aerospace kev lag luam:

Sib sib zog nqus bore machining yog ua hauj lwm nyob rau hauv kev tsim ntawm aircraft tsaws iav, qhov chaw rau lub dav hlau cav, nyoob hoom qav taub rotor shafts, thiab lwm yam tseem ceeb Cheebtsam uas xav tau tshwj xeeb precision thiab durability.

Kev lag luam roj thiab roj:

Qhov tob qhov drilling yog siv rau hauv kev tsim cov cuab yeej siv hauv kev tshawb nrhiav roj thiab roj, suav nrog cov cuab yeej drilling, lub taub dej, thiab cov tubing ntau lawm.

Automotive kev lag luam:

Kev tsim cov khoom siv cav xws li crankshafts, camshafts, txuas cov pas nrig, thiab cov roj txhaj tshuaj yuav tsum muaj kev sib xyaw ntawm qhov sib sib zog nqus.

Kev kho mob thiab kev kho mob:

Lub qhov tob machining yog qhov tseem ceeb hauv kev tsim cov cuab yeej phais, kev cog lus, thiab cov cuab yeej kho mob uas yuav tsum tau ua kom tiav cov khoom siv sab hauv thiab cov khoom tiav.

Kev lag luam pwm thiab tuag:

Qhov tob qhov drilling pom daim ntawv thov nyob rau hauv kev tsim cov pwm txhaj tshuaj, extrusion tuag, thiab lwm yam cuab yeej cuab tam uas yuav tsum tau intricate cua txias raws kom zoo dissipate tshav kub.

Tuag thiab kho pwm:

Lub qhov sib sib zog nqus machining tshuab kuj tseem siv rau kev kho lossis hloov kho cov pwm uas twb muaj lawm thiab tuag, tso cai rau qhov drilling ntawm cov cua txias, ejector pin qhov, lossis lwm yam tsim nyog.

Qhov sib sib zog nqus ua tshuab: rau feem ntau siv qauv

Dab tsi yog qhov sib sib zog nqus ua haujlwm?

Lub qhov tob yog ib qho uas nws qhov sib piv ntawm qhov ntev rau txoj kab uas hla yog ntau dua 10. Qhov tob-rau txoj kab uas hla piv rau qhov sib sib zog nqus feem ntau yog L / d> = 100.Cov no suav nrog lub tog raj kheej qhov zoo li cov roj axial, hollow spindle, thiab hydraulic li qub.Cov qhov no feem ntau xav tau qhov tseeb thiab qhov zoo ntawm qhov chaw, thaum qee cov ntaub ntawv nyuaj rau machinate, uas tuaj yeem ua teeb meem hauv kev tsim khoom.Dab tsi yog qee txoj hauv kev uas koj tuaj yeem xav txog kev ua cov qhov tob?

1. Kev xyaum Drilling

Kev xyaum twist, tsim los ntawm cov neeg Asmeskas, yog lub hauv paus ntawm kev sib sib zog nqus qhov.Lub laum me me no muaj cov qauv yooj yim, thiab nws yooj yim los qhia cov kua txiav, tso cai rau cov khoom siv tho yuav tsum tau tsim nyob rau hauv txawv diameters thiab ntau thiab tsawg.

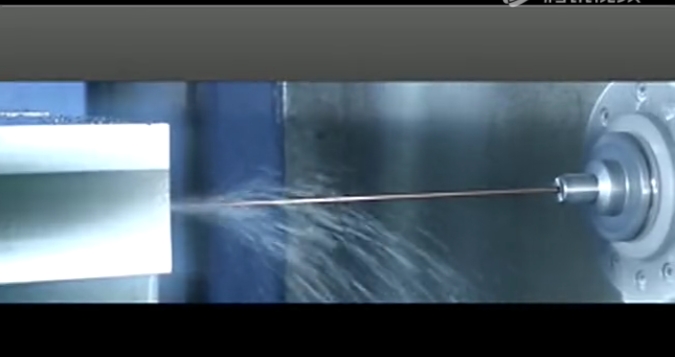

2. rab phom xyaum

Qhov sib sib zog nqus lub raj laum yog thawj zaug siv los tsim cov phom phom, tseem hu ua lub qhov tob tob.Phom laum tau muaj npe li ntawd vim hais tias cov thoob tsis seamless precision raj thiab cov txheej txheem ntau lawm raj tsis tuaj yeem ua tau raws li qhov yuav tsum tau ua.Kev sib sib zog nqus qhov ua tam sim no yog ib txoj hauv kev nrov thiab muaj txiaj ntsig ntawm kev ua haujlwm vim yog kev txhim kho ntawm kev tshawb fawb thiab thev naus laus zis thiab kev siv zog ntawm cov tuam ntxhab ntawm cov tshuab sib sib zog nqus.Lawv tau siv ntau lub teb, suav nrog: kev lag luam tsheb, aerospace, kev tsim kho, khoom siv kho mob, pwm / cuab yeej / jig, hydraulic thiab kev lag luam siab.

Phom drilling yog ib qho kev daws teeb meem zoo rau kev ua qhov tob tob.Phom drilling yog ib txoj hauv kev zoo kom ua tiav cov txiaj ntsig zoo.Phom drilling tuaj yeem ua tiav cov txiaj ntsig ua tiav.Nws muaj peev xwm ua tau ntau yam ntawm qhov sib sib zog nqus thiab tseem muaj qhov tshwj xeeb sib sib zog nqus xws li qhov muag tsis pom qhov thiab qhov hla qhov.

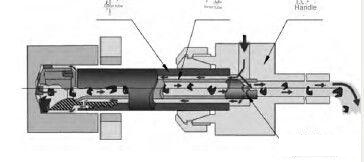

Phom Drilling System Cheebtsam

Phom laum khoom

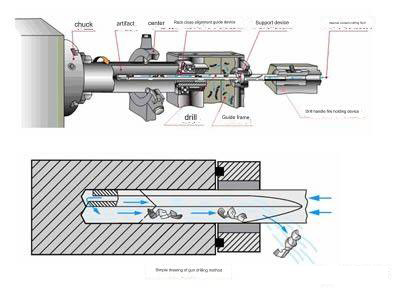

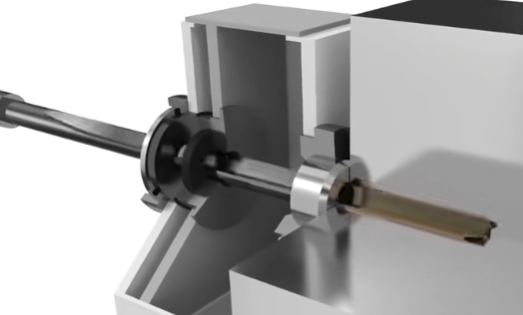

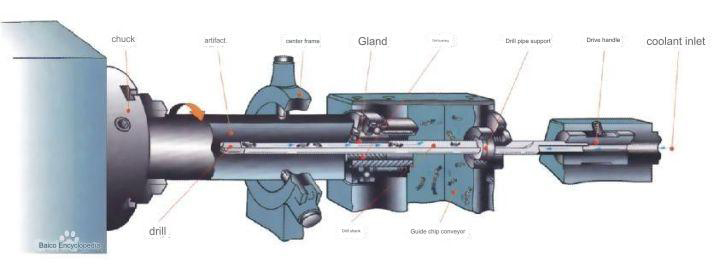

3. BTA system

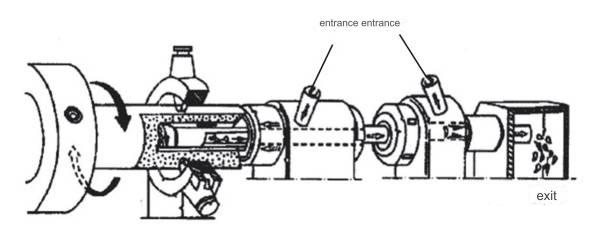

Lub Koom Haum International Hole Processing Association tau tsim ib lub qhov tob tob uas tshem cov chips los ntawm sab hauv.BTA system siv lub tog raj kheej hollow rau lub laum pas nrig thiab me ntsis.Qhov no txhim kho rigidity ntawm lub cuab yeej thiab tso cai rau kev sib dhos ceev thiab disassembly.Daim duab qhia nws txoj hauv kev ua haujlwm.Cov roj dispenser yog ntim nrog cov kua txiav hauv qab siab.

Cov kua txiav ces hla dhau qhov chaw annular tsim los ntawm cov yeeb nkab laum, lub qhov phab ntsa thiab ntws mus rau qhov chaw txiav kom txias thiab lubrication.Nws kuj tseem nias lub nti rau hauv daim ntawv ntawm lub laum me ntsis.Lub laum yeeb nkab lub puab kab noj hniav yog qhov uas cov chips raug tso tawm.BTA system tuaj yeem siv rau qhov sib sib zog nqus qhov taub nrog txoj kab uas hla ntau dua 12 hli.

BAT system muaj pes tsawg leeg ↑

BAT laum ntsis ↑

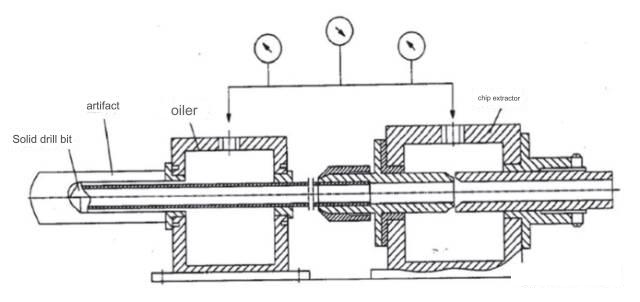

4. Txhaj thiab nqus Drilling System

Jet Suction Drilling System yog ib qho kev sib sib zog nqus qhov drilling txheej txheem uas siv ob lub raj raws li cov kua dej mechanics 'jet suction txoj cai.Cov tshuaj tsuag-suction system yog ua los ntawm ob txheej txheej raj.Tom qab raug pressurized, cov kua txiav yog txhaj los ntawm inlet.Lub 2/3 ntawm cov kua txiav uas nkag mus rau hauv qhov chaw nruab nrab ntawm cov kab laum sab nrauv thiab sab hauv ntws mus rau hauvcnc kev cai txiav qhovkom txias thiab lubricate nws.

Cov chips raug thawb mus rau hauv kab noj hniav.Qhov seem 1/3 ntawm cov kua txiav yog txau ntawm kev kub ceev mus rau hauv cov yeeb nkab sab hauv los ntawm lub crescent zoo li nozzle.Qhov no tsim ib cheeb tsam uas tsis tshua muaj siab nyob rau hauv cov yeeb nkab hauv kab noj hniav, nqus cov kua txiav uas nqa cov chips.Cov chips raug tso tawm sai sai los ntawm qhov hluav taws xob nyob rau hauv ob qho tshuaj tsuag thiab nqus.Jet suction drilling tshuab yog tsuas yog siv rau kev sib sib zog nqus qhov, nrog ib txoj kab uas hla ntau dua 18mm.

Txoj cai ntawm dav hlau suction drilling system ↑

Dav hlau suction laum ntsis ↑

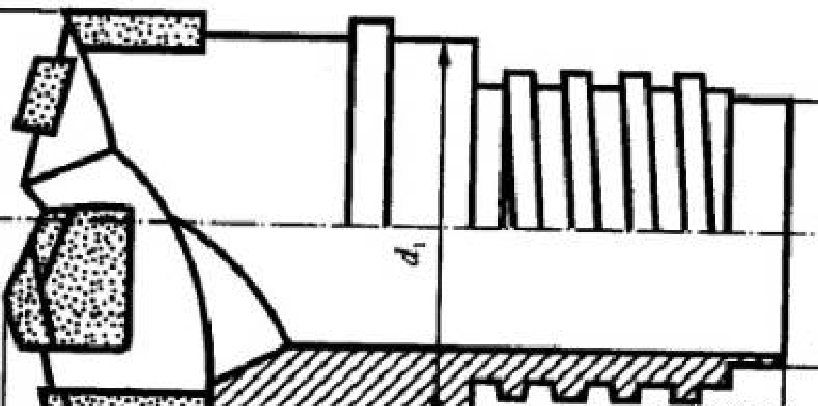

5. DF system

DF system yog ib tug dual-inlet ib leeg-tube sab hauv nti tshem tawm system tsim los ntawm Nippon Metallurgical Co., Ltd. Cov kua txiav yog muab faib ua ob sab pem hauv ntej thiab nram qab ceg, uas nkag los ntawm ob inlets feem.2/3 ntawm cov kua txiav nyob rau hauv thawj ib ntws mus rau lubcnc hlau txiav qhovlos ntawm thaj tsam annular tsim los ntawm lub laum yeeb nkab thiab phab ntsa ntawm lub qhov ua tiav, thiab thawb cov chips mus rau hauv lub qhov hluav taws xob nti ntawm lub laum me ntsis, nkag mus rau hauv lub laum yeeb nkab, thiab ntws mus rau lub chip extractor;tom kawg ib qho 1/3 ntawm cov kua txiav ncaj qha nkag mus rau hauv nti extractor thiab yog nrawm los ntawm qhov sib txawv ntawm qhov nqaim conical ntawm lub hauv ntej thiab nram qab nozzles, tsim kom muaj qhov tsis zoo siab nqus cov nyhuv kom ua tiav lub hom phiaj ntawm kev tshem tawm nti.

Cov qauv ntawm thawj ib nrab ntawm DF system uas ua lub luag haujlwm "thawb" zoo ib yam li BTA system, thiab cov qauv ntawm ib nrab thib ob uas ua lub luag haujlwm "suction" zoo ib yam li lub dav hlau nqus dej drilling. qhov system.Txij li thaum lub DF system siv ob lub roj inlet li, nws tsuas yog siv ib tug laum yeeb nkab.Lub nti thawb thiab suctioning txoj kev ua tiav, yog li txoj kab uas hla ntawm lub laum pas nrig tuaj yeem ua rau me me thiab qhov me me tuaj yeem ua tiav.Tam sim no, qhov tsawg kawg nkaus txoj kab uas hla ntawm DF system tuaj yeem ncav cuag 6 hli.

DF system ua haujlwm li cas ↑

DF sib sib zog nqus qhov laum ntsis ↑

6. SIED system

North China University invented lub SIED system, ib tug tib raj nti ejection system thiab suction laum system.Cov thev naus laus zis no yog ua raws li peb txoj hauv kev tshem tawm cov cuab yeej drilling: BTA (jet-suction laum), DF system, thiab DF System.Lub kaw lus ntxiv rau nws tus kheej adjustable nti extraction ntaus ntawv uas yog powered los ntawm lub hwj chim mov los tswj cov cua txias thiab nti tshem tawm cov kua ntws ntawm nws tus kheej.Raws li pom hauv daim duab, qhov no yog lub hauv paus ntsiab lus.Lub twj tso kua mis hydraulic tso tawm cov kua dej txiav tawm, uas tau muab faib ua ob lub kwj dej: thawj cov kua dej nkag mus rau hauv cov khoom siv roj thiab ntws los ntawm qhov sib txawv ntawm lub laum yeeb nkab phab ntsa thiab lub qhov kom ncav cuag qhov txiav, tshem cov chips.

Thawj cov kua dej yog thawb rau hauv lub qhov hluav taws xob ntawm lub laum me ntsis.Qhov thib ob txiav kua nkag los ntawm qhov sib txawv ntawm conical nozzle khub thiab ntws mus rau hauv lub nti extraction ntaus ntawv.Qhov no tsim lub dav hlau siab ceev thiab tsis zoo siab.SIED yog nruab nrog ob lub siab tswj lub siab, ib qho rau txhua qhov dej ntws.Cov no tuaj yeem hloov kho raws li qhov zoo tshaj plaws txias los yog nti rho tawm tej yam kev mob.SlED yog ib qho system uas tau maj mam nce.Nws yog ib tug ntau sophisticated system.Lub SlED system tam sim no muaj peev xwm txo qhov tsawg kawg nkaus txoj kab uas hla ntawm lub qhov drilling kom tsawg dua 5 hli.

SIED system ua haujlwm li cas ↑

Daim ntawv thov ntawm qhov sib sib zog nqus ua hauv CNC

Kev tsim cov phom thiab riam phom:

Drilling qhov tob yog siv los ua phom thiab riam phom tshuab.Nws paub tseeb qhov ntev, phom sij thiab qhov chaw tiav rau qhov tseeb thiab txhim khu kev qha phom.

Aerospace kev lag luam:

Cov txheej txheem sib sib zog nqus-qhov machining yog siv los ua qhov chaw rau tsaws iav ntawm lub dav hlau nrog rau lub cav cav qhov chaw thiab ntau lwm yam tseem ceeb hauv aerospace uas yuav tsum tau ua kom zoo thiab raug.

Tshawb nrhiav roj thiab roj:

Drilling qhov sib sib zog nqus yog siv los tsim cov khoom siv xws li cov khoom siv tho, cov kav dej, raws li qhov zoo, uas yog qhov tseem ceeb rau kev tshawb nrhiav roj thiab roj.Qhov sib sib zog nqus tso cai rho tawm cov peev txheej uas raug kaw hauv cov dej hauv av.

Automotive kev lag luam:

Kev ua haujlwm ntawm qhov sib sib zog nqus yog qhov tseem ceeb rau kev tsim cov khoom siv cav xws li crankshafts, camshafts thiab txuas cov pas nrig.Cov Cheebtsam no xav tau qhov tseeb hauv lawv cov yam ntxwv sab hauv thiab ua tiav rau qhov ua tau zoo tshaj plaws.

Kev kho mob thiab kev kho mob:

Ib txoj kev sib sib zog nqus-qhov machining yog siv los ua cov cuab yeej phais, kev kho mob cog nrog rau cov cuab yeej kho mob sib txawv.Cov khoom siv no xav tau cov yam ntxwv sab hauv thiab ua tiav kom ntseeg tau tias qhov ua tau zoo tshaj plaws thiab kev sib raug zoo.

Kev lag luam pwm thiab tuag:

Qhov sib sib zog nqus qhov laum ua lub luag haujlwm tseem ceeb hauv kev tsim cov pwm zoo li tuag.Pwm thiab tuag yuav tsum tau cov cua txias kom ua kom muaj cua sov kom zoo thaum siv cov txheej txheem xws li txhaj tshuaj molding lossis cov txheej txheem tsim khoom sib txawv.

Kev lag luam hluav taws xob:

Kev sib sib zog nqus qhov yog siv rau kev tsim khoom ntawm cov khoom siv hluav taws xob, xws li turbine blades, heat exchangers thiab fais fab kis.Cov khoom no feem ntau xav tau cov kev qhia tshwj xeeb hauv sab hauv thiab ua tiav kom ntseeg tau tias kev ua haujlwm ntawm lub zog tsim.

Kev lag luam kws muaj txuj ci:

Drilling qhov sib sib zog nqus yog siv rau hauv kev tsim cov kev tiv thaiv ntsig txogcnc milled qhov chawzoo li cov missile qhia systems thiab armor daim hlau thiab aerospace tsheb Cheebtsam.Cov nocnc machined Cheebtsamyuav tsum tau high-precision thiab kav ntev ntev los xyuas kom meej lawv cov hauj lwm zoo thiab kev ruaj ntseg.

Anebon muaj peev xwm muab cov khoom lag luam zoo, cov nqi muag khoom sib tw thiab cov neeg siv khoom zoo tshaj plaws.Anebon lub hom phiaj yog "Koj tuaj ntawm no nrog kev nyuaj thiab peb muab rau koj nrog luag nyav kom tshem tawm" rau kev cai hlau stamping kev pab cuam.Tam sim no Anebon tau them nyiaj rau kev txiav txim siab ntawm txhua qhov tshwj xeeb los lav txhua yam khoom lossis kev pabcuam txaus siab los ntawm peb cov neeg yuav khoom.

Peb kuj muab OEM anodized hlau thiab lazer txiav cov kev pabcuam uas haum rau koj cov kev xav tau tshwj xeeb thiab cov kev xav tau.Nrog pab pawg muaj zog ntawm cov kws tshaj lij engineers hauv kev tsim hose thiab kev tsim kho, Anebon ua tib zoo saib xyuas txhua lub sijhawm los muab cov khoom lag luam zoo tshaj plaws thiab cov kev daws teeb meem rau peb cov neeg siv khoom.

Yog tias koj xav paub ntau ntxiv, thov hu rau tus thawj coj saib xyuas Anebon ntawm info@anebon.com, xov tooj+86-769-89802722

Post lub sij hawm: Oct-27-2023