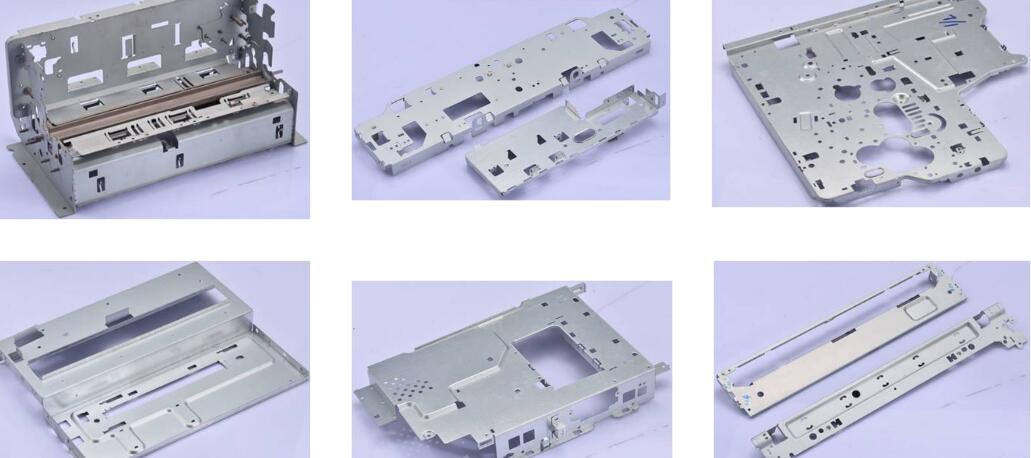

Sheet Hlau Fabrication

Raws li cov cuab yeej ua tiav thiab tuag khw, peb muaj kev txawj ntse hauv txhua qhov chaw ntawm kev tsim khoom xws li fiber ntau laser, CNC xuas nrig ntaus, CNC dabtsi yog khoov, CNC sib sau, vuam, CNC machining, kho vajtse insertion thiab sib dhos.

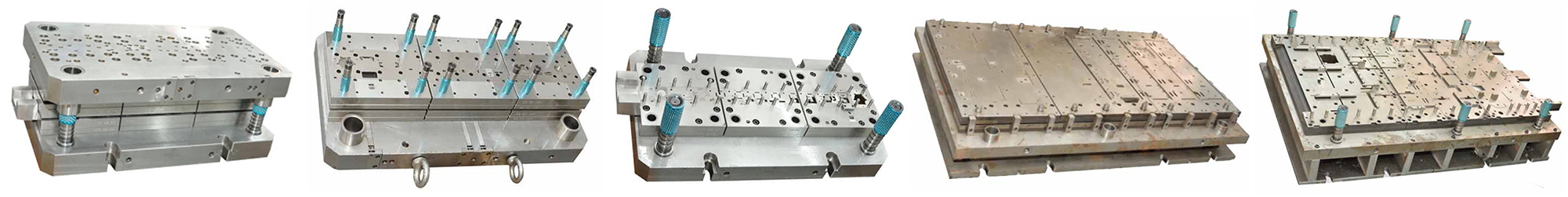

Peb lees txais cov khoom siv raw hauv cov ntawv, phaj, tuav lossis cov raj thiab muaj kev paub txog kev ua haujlwm nrog ntau yam ntaub ntawv xws li txhuas, tooj liab, stainless hlau thiab carbon steels.Lwm cov kev pabcuam suav nrog kho vajtse ntxig, vuam, sib tsoo, machining, tig thiab sib dhos.Raws li koj qhov ntim ntau ntxiv peb kuj muaj kev xaiv ntawm cov cuab yeej nyuaj rau koj qhov chaw khiav hauv peb lub tuam tsev hlau stamping.Kev tshuaj xyuas cov kev xaiv muaj los ntawm kev txheeb xyuas qhov yooj yim txhua txoj hauv kev los ntawm FAIR & PPAP.

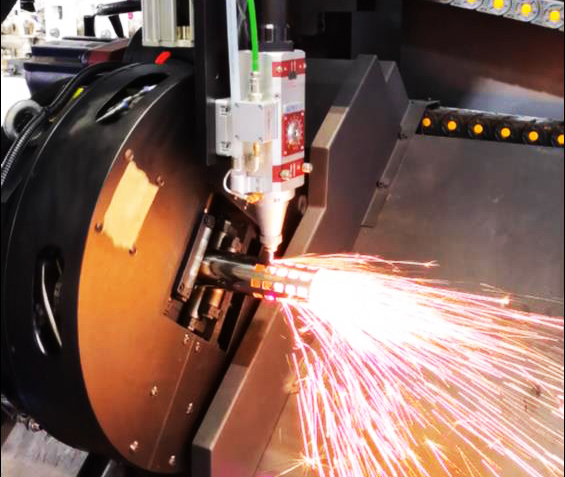

Laser Txiav

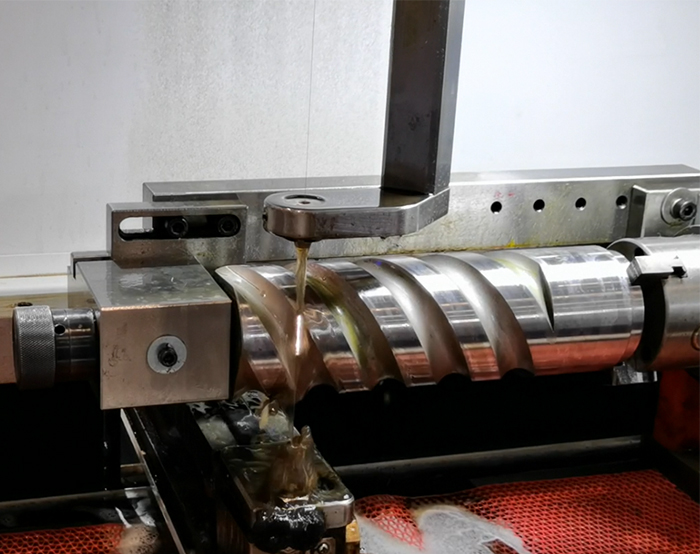

Hlau dabtsi yog khoov

WEDM

Vuam

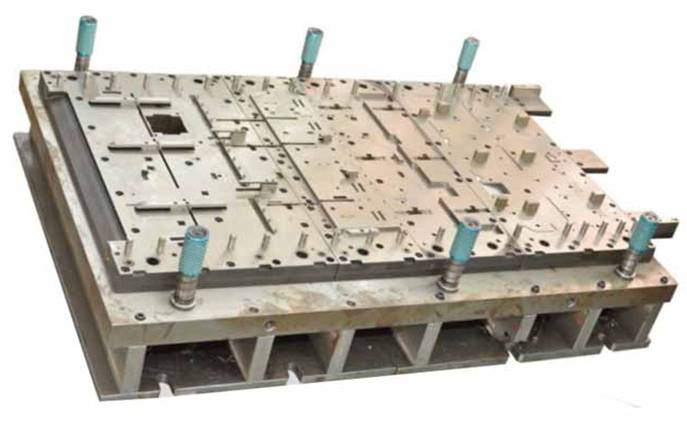

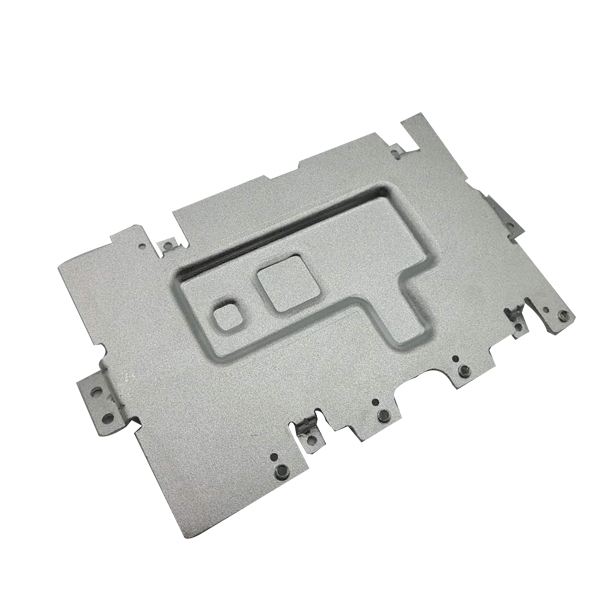

Stamping Service

Peb yuav siv peb cov cuab yeej siv siab heev thiab pab pawg neeg paub txog los kho cov khoom koj xav txog, thiab peb ntseeg tias peb tuaj yeem ua tau raws li koj xav tau ob qho tib si ntawm tus nqi thiab zoo.

Stamping yog dab tsi?

Cov ntawv hlau yog tsim rau hauv ntau yam ntawv zoo li qhov chaw thiab lub plhaub, lub thawv zoo li cov khoom ua haujlwm ntawm cov xovxwm los ntawm pwm, los yog cov raj raj yog ua rau ntau yam tubular workpieces.Hom txheej txheem no nyob rau hauv lub xeev txias yog hu ua txias stamping, hu ua stamping.

Stamping processing yog cov cuab yeej tsim khoom ntawm cov khoom lag luam nrog qee cov duab, qhov loj thiab kev ua tau zoo los ntawm lub zog ntawm cov khoom siv los yog cov khoom tshwj xeeb stamping, uas ncaj qha deforms thiab deforms daim ntawv hauv pwm.Cov ntawv, pwm thiab cov khoom siv yog peb lub ntsiab ntawm stamping.

Hom txheej txheem tseem ceeb: xuas nrig ntaus, khoov, shearing, kos duab, bulging, spinning, kho.

Daim ntawv thov: Aviation, tub rog, machinery, ua liaj ua teb machinery, electronics, ntaub ntawv, railways, post thiab telecommunications, tsheb thauj mus los, tshuaj, khoom siv kho mob, khoom vaj khoom tsev thiab lub teeb kev lag luam.

Yam ntxwv

Peb siv cov pwm precision, qhov precision ntawm lub workpiece tuaj yeem ncav cuag micron theem, thiab qhov kev rov ua dua yog siab, cov lus qhia tshwj xeeb yog tib yam, thiab lub qhov thiab cov thawj coj tuaj yeem raug punched.

(1) Peb cov txheej txheem stamping yog qhov ua tau zoo, ua haujlwm yooj yim, thiab yooj yim rau kev siv tshuab thiab automate.Tus naj npawb ntawm strokes ntawm ib qho xovxwm yog txog li ob peb kaum zaus hauv ib feeb, thiab lub siab ceev tuaj yeem yog ntau pua lossis ntau txhiab zaus hauv ib feeb, thiab punch tuaj yeem tau txais rau txhua qhov xovxwm.

(2) Txij li cov tuag tau lees paub qhov loj thiab cov duab raug ntawm qhov chaw stamping thaum lub sij hawm stamping, thiab feem ntau tsis ua rau qhov zoo ntawm qhov chaw stamping, thiab lub neej ntawm cov tuag feem ntau yog ntev, qhov zoo ntawm stamping yog ruaj khov, kev sib hloov pauv tau zoo, thiab nws muaj "zoo ib yam".Yam ntxwv.

(3) Peb tuaj yeem nias thiab ua cov txheej txheem nrog cov loj loj thiab cov duab, xws li stopwatches me me raws li lub moos, kom deb li deb ntawm lub tsheb longitudinal beams, npog qhov chaw, thiab lwm yam., ntxiv rau qhov txias deformation hardening nyhuv ntawm stamping cov ntaub ntawv, xuas nrig ntaus lub zog thiab nruj siab dua.

(4) Stamping feem ntau tsis muaj chips scraps, tsawg dua cov khoom siv, thiab tsis xav tau lwm yam khoom siv cua sov.Yog li ntawd, nws yog ib qho khoom-txuag thiab txuag hluav taws xob ua, thiab tus nqi ntawm stamping qhov chaw yog tsawg.

Cov khoom