Tuag Casting Service

Tuag casting tau tshwj xeeb ntawm Anebon rau ntau tshaj 10 xyoo.Peb cov kev pabcuam txhuas casting tau pab engineers, cov khoom tsim thiab cov kws tsim qauv coj lawv cov qauv tsim rau lub neej nrog lub xeev ntawm cov kos duab ib feem tsim thiab txhim khu kev qha zoo.Muab peb cov kev paub dhau los hauv kev lag luam, ua ke nrog peb cov khoom siv hauv lub xeev, peb cov kws tshaj lij kev tsim khoom thiab cov kws ua haujlwm zoo, thiab cov neeg ua haujlwm tsim khoom, koj tau lees paub kev tsim khoom zoo ntawm koj cov khoom thiab cov khoom ntawm tus nqi pheej yig nrog Anebon.Peb yog ib qho ISO 9001: 2015 certified tuag casting chaw tsim tshuaj paus tshwj xeeb nyob rau hauv tuag casting cov kev pab cuam rau lub ntiaj teb no txoj kev industries thiab tuam txhab uas muag.Peb cov khoom siv npog yuav luag txhua qhov tuag casting engineering, tsim thiab kev tsim kho xav tau koj lub tuam txhab yuav xav tau.

Casting cov cuab yeej thiab pwm yog kim, yog li cov txheej txheem tuag casting feem ntau tsuas yog siv los tsim cov khoom lag luam ntau.Nws yog ib qho yooj yim los tsim cov khoom siv tuag-cam khwb cia, uas feem ntau yuav tsum tsuas yog plaub kauj ruam tseem ceeb, nrog rau ib qho nqi nce qis.Tuag casting yog tshwj xeeb tshaj yog haum rau kev tsim ntawm ib tug loj tus naj npawb ntawm cov me me thiab nruab nrab-qhov loj me castings, yog li tuag casting yog feem ntau lug siv ntawm ntau yam txheej txheem casting.Piv rau lwm cov txheej txheem casting, qhov tuag-cam khwb cia saum npoo yog flatter thiab muaj qhov sib npaug siab dua.

Tuag Casting yog dab tsi?

Tuag casting yog txheej txheem hlau casting yam ntxwv los ntawm kev siv cov pwm kab noj hniav los thov kev kub siab rau cov hlau molten.Pwm feem ntau yog ua los ntawm cov hlau alloys siab dua, qee qhov zoo ib yam li kev txhaj tshuaj molding.Feem ntau cov tuag castings yog hlau tsis muaj hlau, xws li zinc, tooj liab, txhuas, magnesium, txhuas, tin, thiab txhuas-tin alloys thiab lwm yam alloys.Nyob ntawm seb hom kev tuag casting, lub tshuab txias chamber tuag casting los yog kub chamber tuag casting tshuab yog yuav tsum tau.

Yam ntxwv

Tuag casting yog ib txoj kev casting nyob rau hauv uas ib tug molten alloy kua yog poured rau hauv lub siab chamber, ib tug kab noj hniav ntawm ib tug steel pwm yog sau nyob rau hauv ib tug kub ceev, thiab cov kua alloy yog solidified nyob rau hauv siab los tsim ib tug casting.Cov yam ntxwv tseem ceeb ntawm kev tuag casting uas paub qhov txawv ntawm lwm txoj kev casting yog kev kub siab thiab kev kub ceev.

1. Cov hlau molten nyob rau hauv cov kab noj hniav nyob rau hauv siab thiab crystallizes ntawm lub siab dua.Qhov siab tshaj plaws yog 15-100 MPa.

2.Cov kua hlau ua rau cov kab noj hniav ntawm kev kub ceev, feem ntau yog 10-50 m / s, thiab qee qhov tuaj yeem tshaj 80 m / s, (kab nrawm los ntawm kev nkag mus rau hauv kab noj hniav - ingate ceev), yog li cov hlau molten lub sij hawm filling yog tsis tshua muaj. luv luv, thiab cov kab noj hniav tuaj yeem ua tiav li ntawm 0.01-0.2 vib nas this (nyob ntawm qhov loj ntawm qhov casting).

Tuag-casting yog ib txoj kev precision casting.Tuag-casting qhov chaw cam khwb cia los ntawm tuag-casting, muaj me me qhov ntev kam rau ua thiab siab precision.Feem ntau, cov khoom tuag-casting tuaj yeem sib sau ua ke yam tsis tau tig.Cov khoom tuaj yeem raug pov ncaj qha.

Dab tsi yog cov txiaj ntsig ntawm kev pabcuam tuag casting?

Peb cov txheej txheem tuag casting muaj ntau yam txiaj ntsig tseem ceeb, suav nrog:

l Customization: Nws pab kom ua tiav cov qauv tsim thiab cov ntaub ntawv uas ua rau nws yooj yim rau customize castings rau cov txheej txheem tsim tshwj xeeb.

ll Tus nqi qis

ll High efficiency

llll Multi-functional thiab corrosion-resistant

Raws li cov chaw tsim khoom tuag-casting, Anebon Die Casting muaj kev ua tiav, kev sib dhos thiab kev sim ntawm txhua qhov tuag-casting thiab cov khoom.Txawm hais tias koj txaus siab rau cov khoom tshwj xeeb xws li txhuas tuag casting lossis lub tshuab nqus tsev tuag casting, lossis tsuas yog xav ua tus qauv ntawm qhov tshiab, koj tuaj yeem tau txais kev pabcuam tag nrho hauv peb lub hoobkas.

Material

Cov hlau peb siv rau kev tuag casting feem ntau suav nrog zinc, tooj liab, txhuas, magnesium, txhuas, tin, thiab txhuas-tin alloys, thiab lwm yam. Txawm hais tias cam khwb cia hlau tsis tshua muaj, nws kuj tseem ua tau.Cov yam ntxwv ntawm ntau yam hlau thaum tuag casting yog raws li nram no:

•Zinc: Qhov yooj yim tshaj plaws tuag-cam khwb cia hlau, kev lag luam thaum tsim khoom me me, yooj yim rau lub tsho loj, siab compressive zog, siab plasticity, thiab lub neej ntev casting.

•Aluminium: High quality, complex manufacturing and thin-walled castings with high dimensional stability, siab corrosion kuj, zoo mechanical zog, siab thermal conductivity thiab hluav taws xob conductivity, thiab siab zog ntawm kub kub.

•Magnesium: Yooj yim rau tshuab, siab zog rau qhov hnyav piv, lub teeb ntawm cov khoom siv feem ntau siv cov hlau tuag.

•Tooj: High hardness thiab muaj zog corrosion kuj.Feem ntau siv cov hlau tuag-cam khwb cia muaj cov khoom siv zoo tshaj plaws, tiv thaiv hnav thiab lub zog ze rau cov hlau.

•Lead thiab tin: High density thiab high dimensional precision rau tshwj xeeb corrosion tiv thaiv qhov chaw.Rau cov laj thawj ntawm kev noj qab haus huv rau pej xeem, cov hlau no tsis tuaj yeem siv los ua khoom noj thiab chaw cia khoom.Lead-tin-bismuth alloys (qee zaum kuj muaj me ntsis tooj liab) tuaj yeem siv los ua cov ntawv ua tiav tes thiab kub stamping hauv letterpress printing.

Aluminium Casting

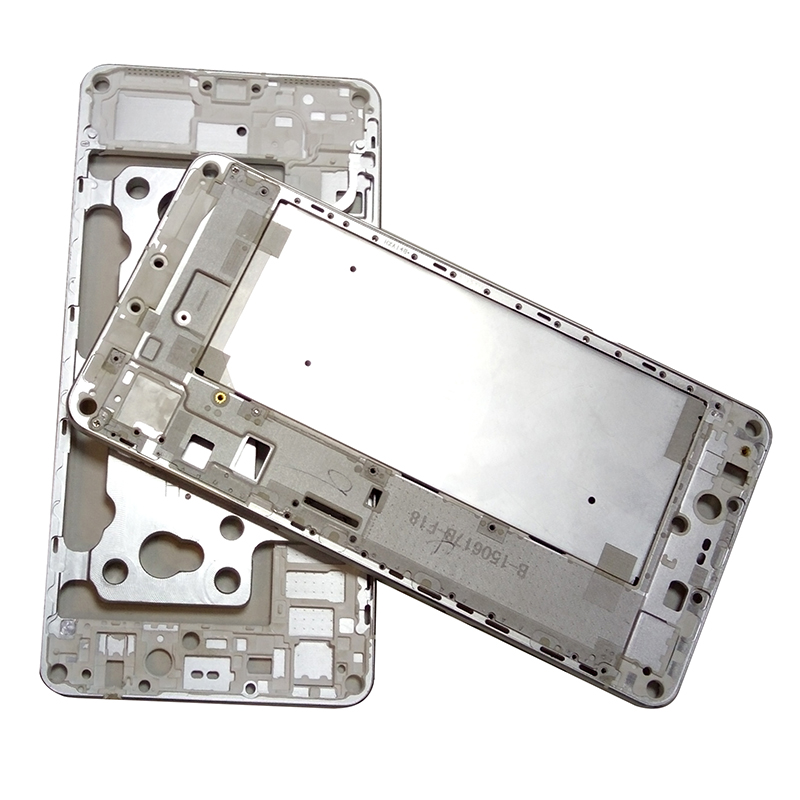

Casting Txawb Xov Tooj Accessories

Aluminium Tuag Cast