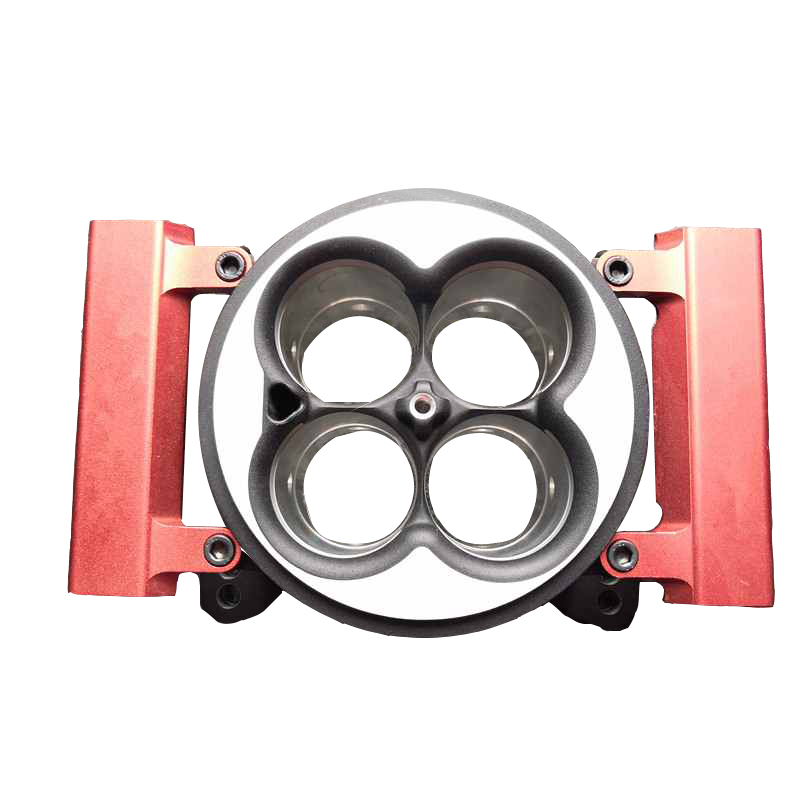

CNC Component

CNC machining auto spare part

precision custom aluminum cnc machining part/cnc machine part/stainless steel machining part

| Product Name | CNC machining auto spare part |

| Material | Aluminum, copper, brass, stainless steel, steel, iron, alloy, zinc etc. |

| Finish | Polishing; Anodized; Sanding Powder coating; Vacuum Plating; Nickel, Zinc, Tin, Silver plating etc. |

| Tolerance | +/-0.01mm |

| Packing | Inner-Plastic Bag; Outer -Standard Carton Box. |

① Usage: All kinds of cars, machinery, home appliance, electronic products, electric appliance, stationery, computers, power switches, miniature switches, architecture, commodity and A/V equipment, hardware and plastic molds, sports equipment and gifts, and more

② Applications:auto,motorcycle,industry,agriculture,mine,furniture,elevator,etc

③ Machining equipment: CNC milling turning machine, general milling turning machine, grinding machine.

④ Service: Warm and quick response service provided by the professional Export Sales Team with many years' experience in handling exports to the US, Europe, Japan and other countries and regions.

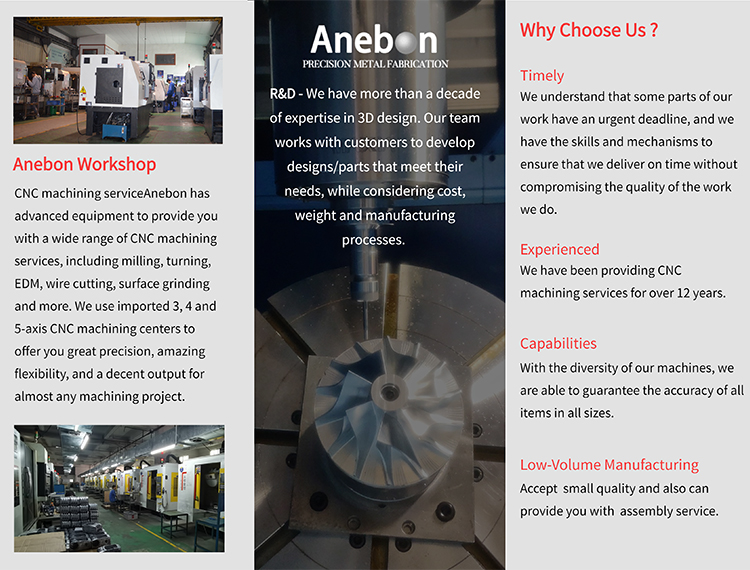

Why choose us:

1,Experience:more than ten years manufacturing history;

2,Price : Reasonable and competitive according to your drawings;

3,quality assurance: To ensure correct standard and choose equivalent standard for material and technique requirements, before running ,we would like to provide formal material certificate

showing chemical compositions and property, also if you need ,we can provide control plan, showing processing and inspection tooling;

4,quanlity control: In house, coming inspection, first off, spotcheck in processing ,final inspection, 100% inspection for critical dimension;

5,Small order accepted;

6,packing:carton box or iron can or depend on your requirements;

7,Delivery:20-30days after confirming order, according to your requirements and production quantity:

8,Payment:By T/T, for samples 100% with the order: for production,50%paid for deposit by T/T before production arrangement, the balance to be paid before shipment. or negotiation;

9,honesty and professional services;

10,Product application: Home appliance equipment, Auto parts, Industrial equipment, Electrical equipment, mechanical parts, hardware parts.

Packaging Details

precision casting part Inner Packing: bubble paper

precision casting part Outer packing: wooden boxes, carton, cardboard box with foam, standard carton box, standard Export Carton.-Customer's Packing Requirement is Acceptable-Box Size