CNC Milling Carbon Fiber Parts

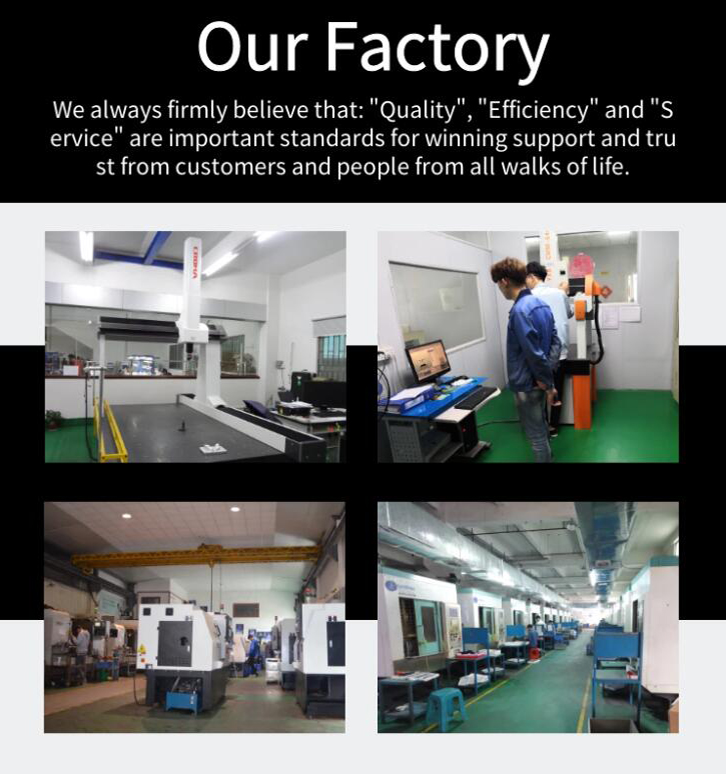

With our leading technology at the same time as our spirit of innovation,mutual cooperation, benefits and growth, we're going to build a prosperous future together with your esteemed firm for High definition Custom Made Carbon Firber and Bronze Machining Made Precision Cnc, Be sure to deliver us your specifications and requirements.

High definition Machining Made Precision Cnc, With the development of the society and economy, our company will continue the "loyalty, dedication, efficiency, innovation" spirit of enterprise, and we will always adhere to the management idea of "would rather lose gold, do not lose customers heart".

| Size | Custom per customer's request |

| Material | carbon fiber sheets |

| Color | Black or customized |

| Finish | Glossy/Matte |

| Pattern | 3K Twill/Plain, UD |

| Process way | carbon fiber forming+CNC Machining |

| Packgae | Standard export carton with foam protective inside |

| Lead time | Generally 10-15 working days |

| cnc lathe | cnc precision machining parts | cnc milling accessories |

| cnc lathe axis | cnc precision milling | cnc milling aluminium |

| cnc lathe services | cnc precision parts | cnc milling aluminum |

Write your message here and send it to us