Stainless Steel Cnc

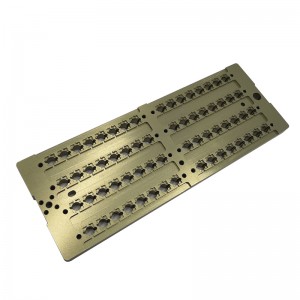

CNC milling is made up of several steps in the process:

CAD model is drawn on a computer by an engineer or designer.

The CAD file is transferred into a CNC-readable program, also known as G-code. This G-code is used to set up the CNC milling machine.

Material is removed from the workpiece using specialized tools rotating has extremely speeds. Accuracy is achieved after initial passes are made and precise amounts of material are removed in the finishing passes.

After milled, the part is deburred, which is a manual process of removing small defects from sharp blade edges by hand. The component is inspection and ready to use.

Words:CNC Milled Parts/ Milling Part/ Milling Accessories/ Milled Part/ 4 axis cnc mill/ axis milling/ cnc milling parts/ cnc milling products

Features:

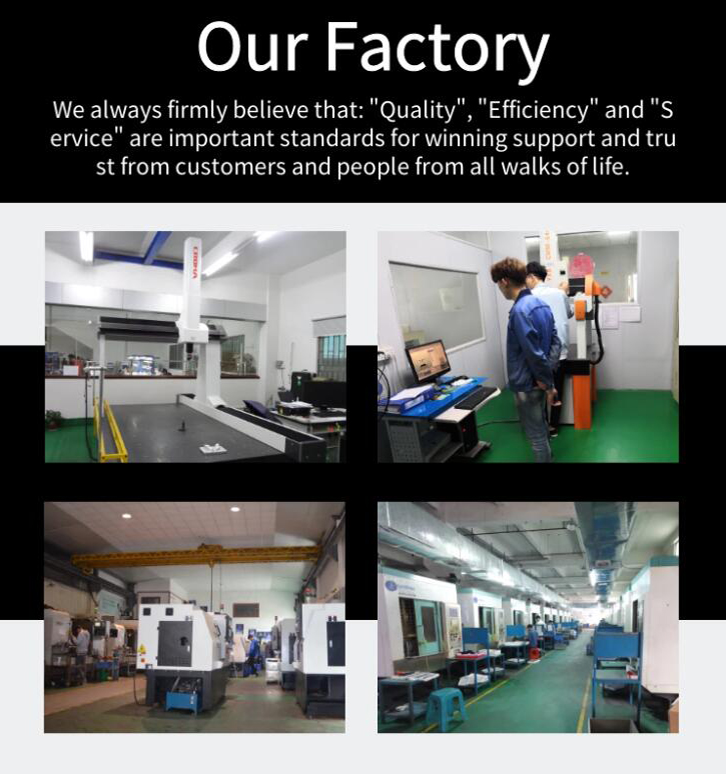

We specialize in CNC turning, CNC Milling, CNC grinding machining services for more than 10 years! Our factory passed ISO9001 certification and our main market is USA, Italy, Japan, Korea, Russia and Belgium.

Packing & Delivery

1. With plastic bag,with pearl-cotton package.

2. To be packed in cartons.

3. Use glues tape to seal cartons.

Or according to customers' requirement.

CNC milling is made up of several steps in the process:

CAD model is drawn on a computer by an engineer or designer.

The CAD file is transferred into a CNC-readable program, also known as G-code. This G-code is used to set up the CNC milling machine.

Material is removed from the workpiece using specialized tools rotating has extremely speeds. Accuracy is achieved after initial passes are made and precise amounts of material are removed in the finishing passes.

After milled, the part is deburred, which is a manual process of removing small defects from sharp blade edges by hand. The component is inspection and ready to use.

Words:CNC Milled Parts/ Milling Part/ Milling Accessories/ Milled Part/ 4 axis cnc mill/ axis milling/ cnc milling parts/ cnc milling products

Features:

We specialize in CNC turning, CNC Milling, CNC grinding machining services for more than 10 years! Our factory passed ISO9001 certification and our main market is USA, Italy, Japan, Korea, Russia and Belgium.

Packing & Delivery

1. With plastic bag,with pearl-cotton package.

2. To be packed in cartons.

3. Use glues tape to seal cartons.

Or according to customers' requirement.

CNC milling is made up of several steps in the process:

CAD model is drawn on a computer by an engineer or designer.

The CAD file is transferred into a CNC-readable program, also known as G-code. This G-code is used to set up the CNC milling machine.

Material is removed from the workpiece using specialized tools rotating has extremely speeds. Accuracy is achieved after initial passes are made and precise amounts of material are removed in the finishing passes.

After milled, the part is deburred, which is a manual process of removing small defects from sharp blade edges by hand. The component is inspection and ready to use.

Words:CNC Milled Parts/ Milling Part/ Milling Accessories/ Milled Part/ 4 axis cnc mill/ axis milling/ cnc milling parts/ cnc milling products

Features:

We specialize in CNC turning, CNC Milling, CNC grinding machining services for more than 10 years! Our factory passed ISO9001 certification and our main market is USA, Italy, Japan, Korea, Russia and Belgium.

Packing & Delivery

1. With plastic bag,with pearl-cotton package.

2. To be packed in cartons.

3. Use glues tape to seal cartons.

Or according to customers' requirement.