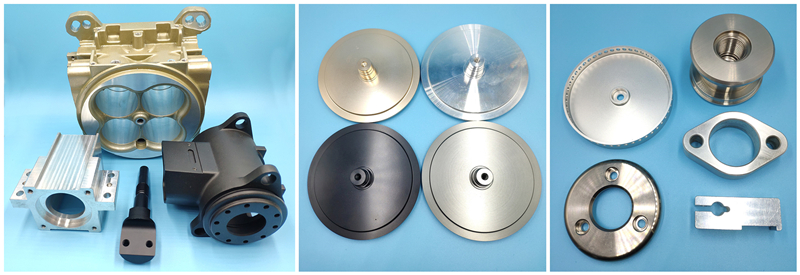

Cnc Machining Titanium

Why choose Anebon?

The production difficulty and processing technology of titanium alloy CNC machining parts are very difficult.

Because of the large cutting force, high cutting temperature, small elastic modulus, uneven initial residual stress, CNC machining deformation, difficult processing, and poor surface quality in the CNC machining of titanium alloys.

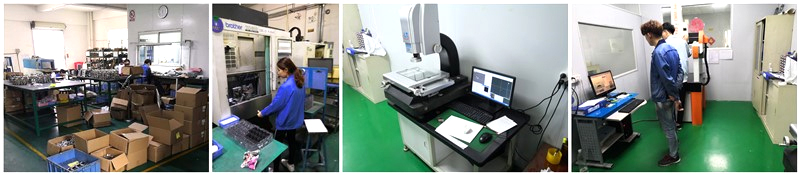

Anebon uses advanced equipment and high-tech engineers to realize the development and production of highly efficient, stable and lean professional titanium alloy parts.

Processing requirements:

Slower cutting speed

Higher cutting feed rate

Hardware settings

Good coolant flow

Very sharp tool

Avoid feed interruption

Good chip maintenance

| Machining Steel | Cnc Production Machining | 3d Milling |

| Medical Machining | Stainless Steel Cnc Machining | Custom Metal |

| Metal Machining | Amazing Cnc Machining | Cnc Milling Process |

Write your message here and send it to us