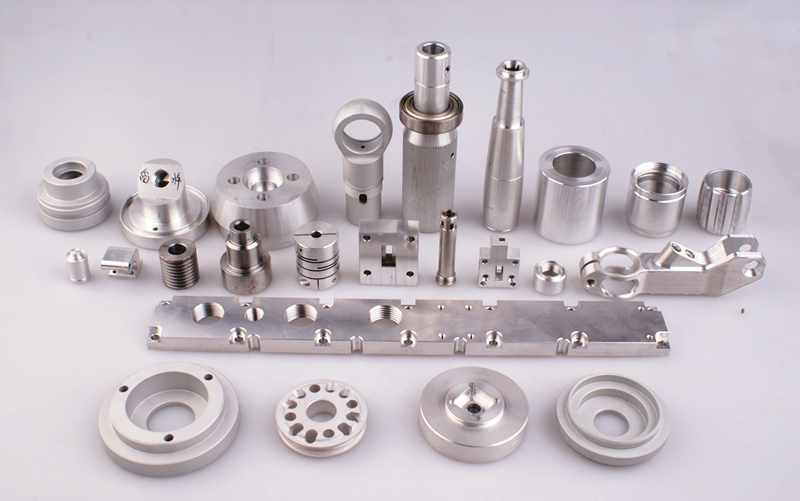

Brass Precision Turned Components

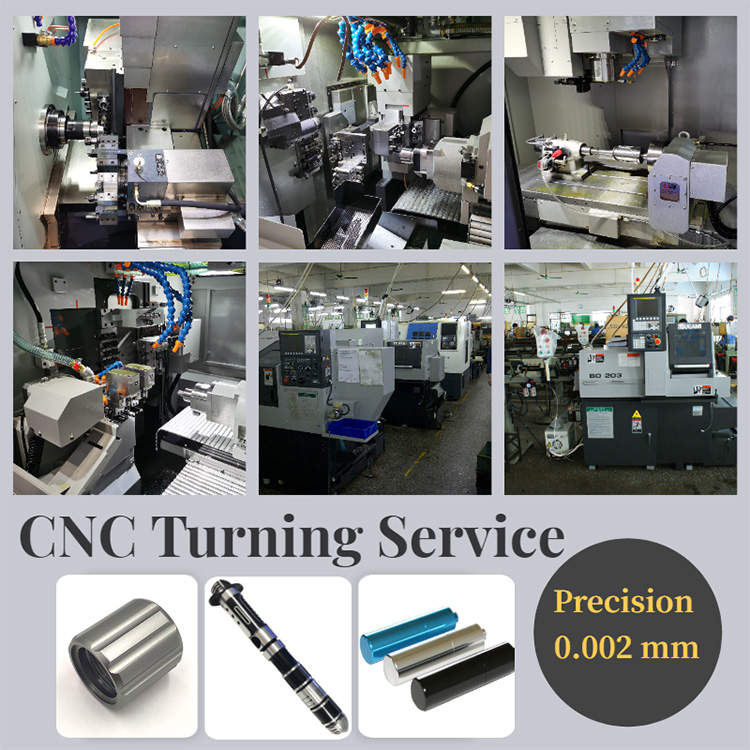

Compared with traditional machining, the cutting speed and feed speed are greatly improved, and the cutting mechanism is different. So far, efficient processing is to ensure the quality of processing at the same time using high spindle speed, large feed, deep cutting for efficient processing.

Tag:cnc lathe accessories/ CNC Lathe Part/ CNC lathe products/ CNC lathe services/ Turning Part/ cnc cutting/ cnc lathe components/ cnc lathe parts

| Product name | custom CNC machining parts |

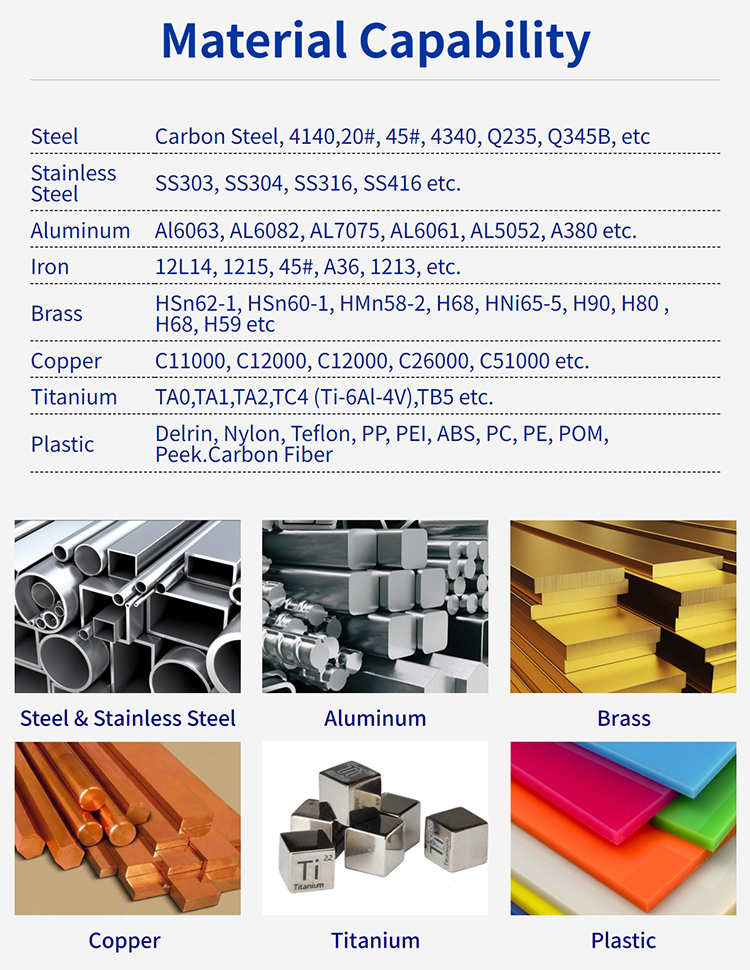

| Material | metal ,plastic or you want material |

| Color | customized |

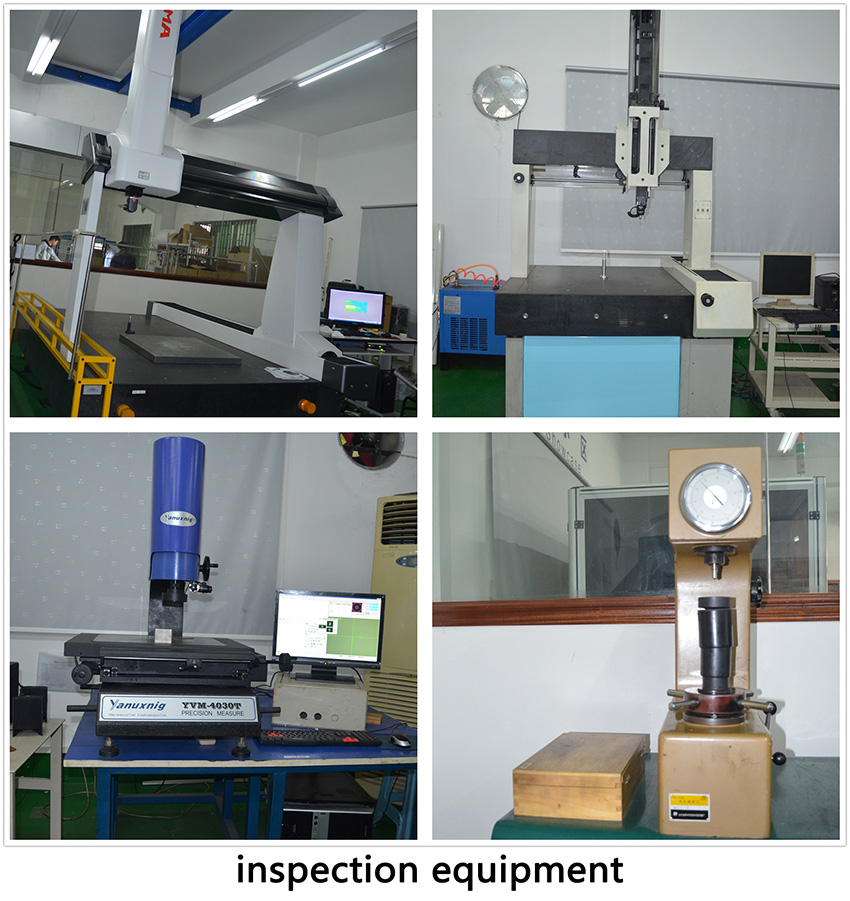

| Certification | ISO 9001:2015&SGS |

| Processing | CNC milling/turning and automatic lathe |

| Size | customized |

| Surface treatment | depend on the requirements of customer |

| Package | PP bag + carton + pallet or depend on the requirements of customer |

| Drawing format | JPEG,PDF,AI,PSD,DWG,DXF,IGS,STEP.CAD |

| Shipment | sea,air or express |

| Application | Automotive,Motorcycle, medical and various mechanical accessories |

About delivery

Write your message here and send it to us