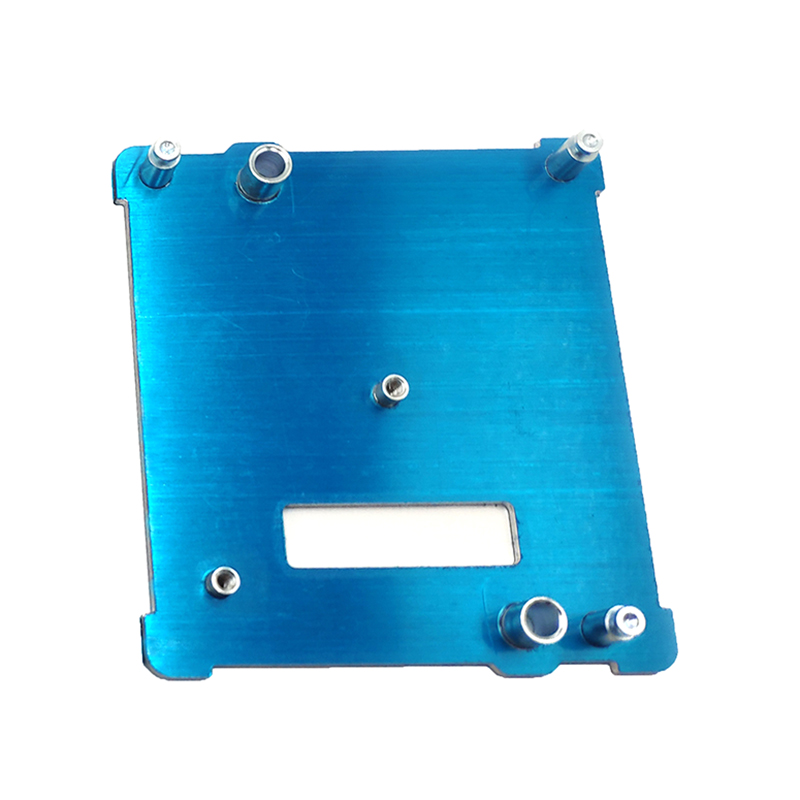

Precision Sheet Metal Stamping Parts

Applied in different industries

The products range is continuously being broadened

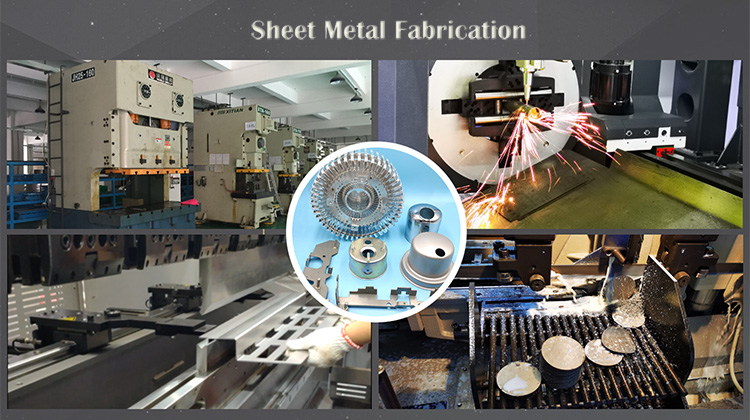

Machine max tonnage is 200T

Average monthly output is 17,500,000 pieces

Various revolving shapes such as tubular, stepped, reverse drawing, spherical, tapered and parabolic are available

In house progressive tooling design and manufacturing

Specific type of surface treatment could help the parts resist more than 400H in salt spray test

Parts could be customized

Our Advantages:

1. Direct factory=competitive price

2. Many years' sheet metal stamping customization history=rich OEM experience

3. Professional technical team = Impeccable products

| Making process | Laser cutting, Stamping, cnc turning and milling ,bending, punching ,threading, welding, tapping, riveting, grinding |

| Thickness | 0.5mm ~12mm, or other special available |

| Inspection | 0.5mm ~12mm, or other special available |

| Mould | Depend on customer's require to make the mould |

| Sample confirmation | Before start mass production we will send the pre-production samples to customer for confirmation.We will modify the mould until customer satisfied |

| Products Scope | Furniture hardware, machine parts, construction hardware, sheet metal processing,machinery parts, hydraulic fitting |

| Packing | According to customer's requirements |

| Certificate | ISO 9001, ROHS |

| Drawing File | 2D:DWG,DXF,PDF 3D:ASM,IGS,STEP,STP .ETC |

Write your message here and send it to us