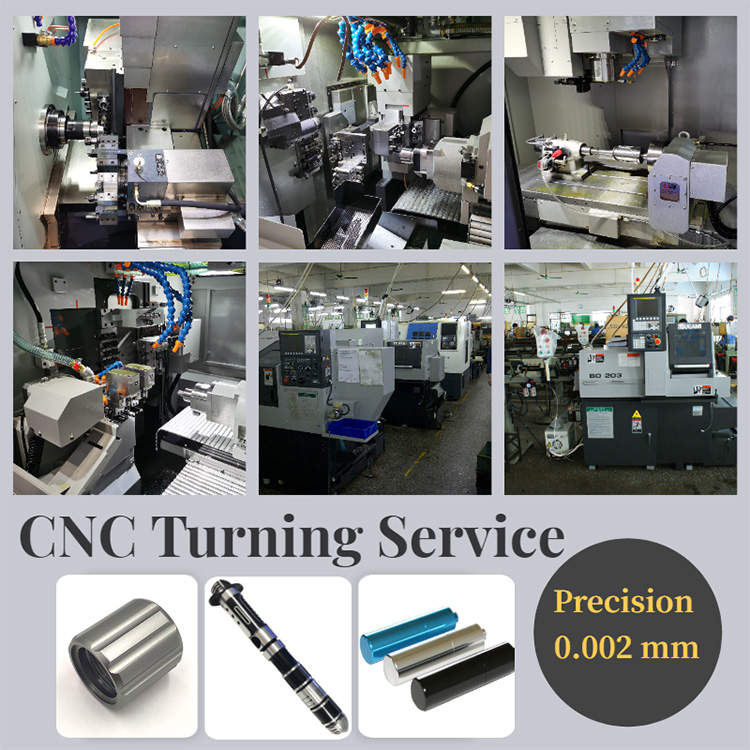

CNC Turned part precision customized plastic part

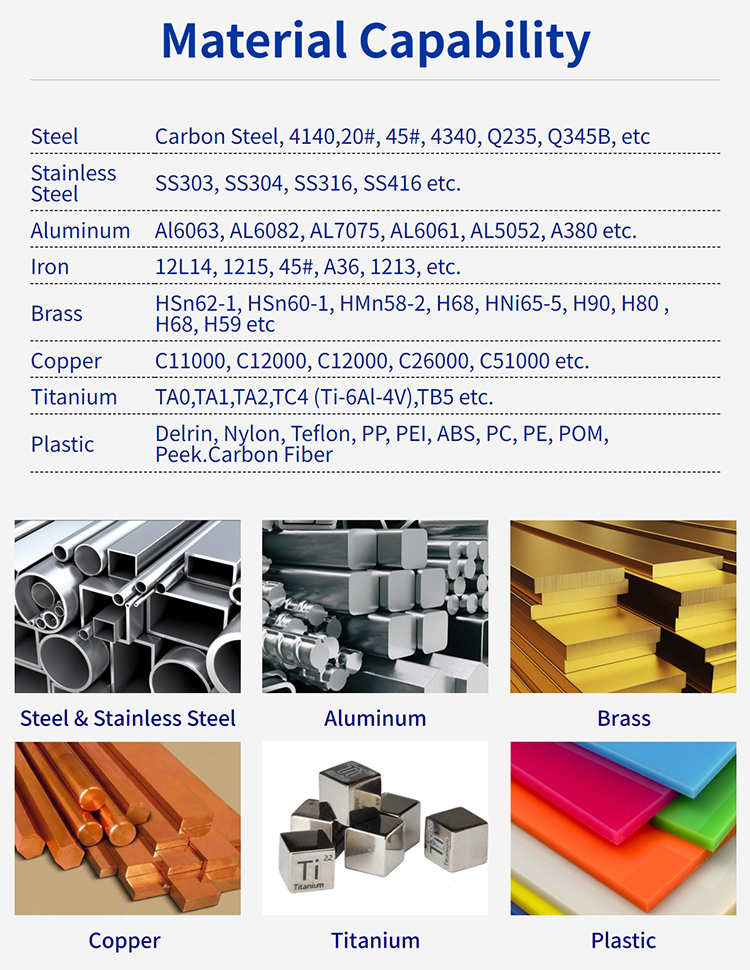

Product Detail:

Capacity:

| CNC Turning | φ0.5 - φ300 * 750 mm | +/-0.005 mm |

| CNC Milling | 510 * 1020 * 500 mm(max) | +/-0.01 mm |

| CNC Stamping | 1000 * 1000 mm(max) | +/-0.05 mm |

| Drawing Format | IGS,STP,X_T ,DXF,DWG , Pro/E, PDF | |

| Test Equipment | measurement instrument, Projector, CMM, Altimeter, Micrometer, Thread Gages, Calipers, Pin Gauge etc. | |

1. CNC Plastic/Metal Prototypes

2. Plastic Injection molding & Plastic Injection mould

3. Vacuum casting/vacuum forming(Silicon Mould)

4. Low Volume Production

5. Rapid Hardware/Sheet Metal Prototypes

6. CNC Aluminum/Brass/Copper/Bronze CNC machining

7. Automotive and medical equipment Prototypes

8. SLA/SLS prototype

9. Metal Stamping & NCT Stamping

10. 3D Printing

11. Die-casting, hardware machining

12. Electronic Manufacturing Service

13. Lathing parts

|

Machining |

Milling |

Turning |

|

Cnc Machining Products |

Cnc Milling Qualifications

|

Cnc Turning Pdf

|

|

Cnc Machining Processes

|

Cnc Milling Prototype

|

Cnc Turning Parts

|

|

Cnc Machining Process

|

Cnc Milling Project

|

Cnc Turning Parts Manufacturer

|

Write your message here and send it to us