Machining Steel CNC metal part

We are able to guarantee our comprehensive cost competitiveness and high quality advantages at the same time for large discount Oem Odm metal products Yolanda Cnc processing services, custom aluminum CNC machining, precision CNC machining parts.

Targeting "zero defects". Take the social responsibility of employees as their responsibility. We welcome friends from all over the world to visit and guide us to achieve a win-win goal.

| Item | Specification |

| Material | Aluminum Alloy:5052 /6061/ 6063 / 2017 / 7075 / etc. |

| Brass Alloy:3602 / 2604 / H59 / H62 / etc. | |

| Stainless Steel Alloy:303 / 304 / 316 / 412 /316/212/316/SUS400, etc. | |

| Steel Alloy:Carbon Steel / Die Steel / etc. | |

| Other Special Materials::Bronze/ Copper alloys/ Lucite / Nylon / Bakelite / Non Metallic Material Parts etc. | |

| We handle many other type of materials. Please contact us if your required material is not listed above. | |

| Surface Treatment | Nickel plating. Zinc plating, Chrome plating, EDM, Black, Nitrogenation. |

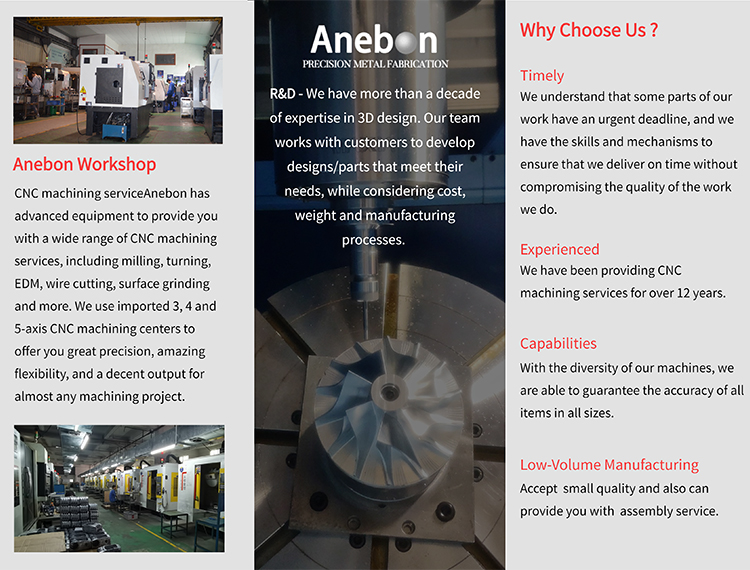

| Machining Equipment | 4-axis CNC Machining Center, CNC Lathe, High Speed Electric Spark Puncher, Milling Machine ,Grinding Machine, CNC Lathes , Wire-cuts , Laser Cuts , CNC Shearing Machines ,CNC Bending Machines, etc. |

| Quality Control and Detection Equipment | Our QC department work is inspection and final inspection. We promise you as below:1. Check the raw material before the production..2. Have inspection during the production.

3. Make 100% inspection before the shipment. Coordinate Measuring Machine, Calipers, Microscope, Micrometer, DEM, Height Meter and 00 Level Marbel Panel, Ring Gauge, Three Pin, Thread Gauge. |

| Quality Assurance | ISO9001:2015 |

Write your message here and send it to us