Aluminum Cnc Turning Parts

Product Detail:

|

Category |

CNC machined components, Graphite products, Shaft collar series etc... |

|

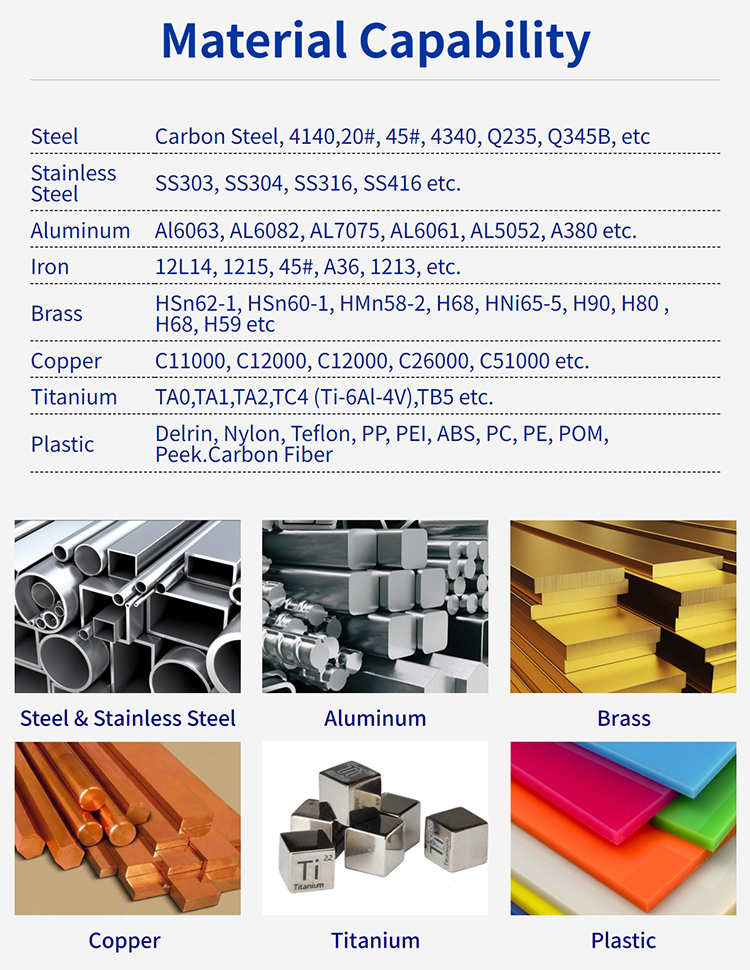

Materials |

Stainless steel, Brass, Bronze, Aluminum, Steel, Copper, Graphite ,Plastic... |

|

Surface treatment |

Zinc, Nickel, Chromate, Copper Tin plating, Passivate, Anodize, Paint... |

|

Metal Fabrication |

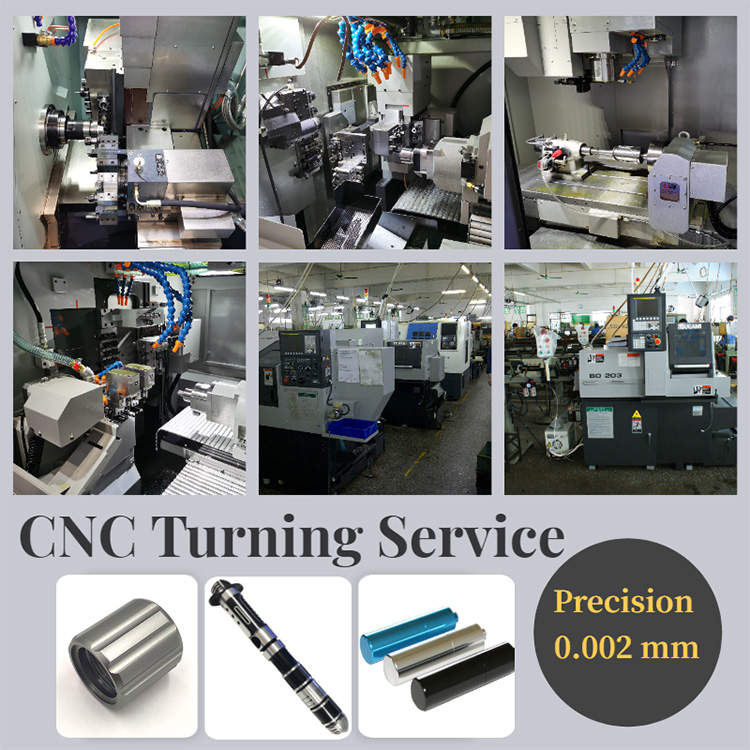

Lathe, Turning, Millling, Engraving, Grinding, Cutting. |

|

Testing Tools |

Projecting profile, Roughness tester, Hardness tester, Concentricity tester |

| CMM, 2D projector, Digital Micrometers, Salt spray tester, all kinds of gages | |

|

Characteristic |

Cnc machining |

|

Package |

Generally carton or wooden case or plastic foam, or as per consumer's requirements |

|

Products Usage |

1. Medical devices |

| 2. Car & Motorcycle parts | |

| 3. Auto accessories | |

| 4. Mechanical components | |

| 5. Hardware parts | |

| 6. Home appliance equipment | |

| 7. Industrial equipment | |

| 8. Electrical equipment etc. | |

|

Price |

Reasonable competitive and negotiable. |

|

Payment Terms |

T/T; L/C, Western Union |

Company Advantages

| 1) Service advantage We provide all kinds of OEM, design services, buyer label services. We have a complete foreign trade service team providing 24-hour online service. We provide life-long service, as long as you are our customers, we will do our best to help you to solve the problem. |

2) Product advantages Quality assurance: Our company strict implementation of ISO quality management. |

| 3) Technical advantage We have our own R & D team. We total have 7 technical engineers including 2 senior engineers who have 20 years working experience and 5 engineers who have the working experience all over 5 years. |

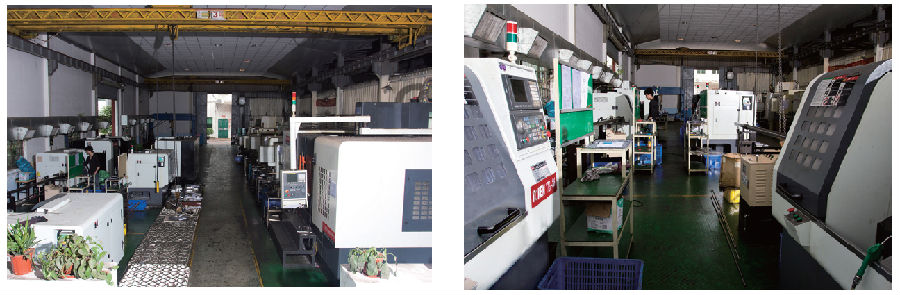

4) Company advantages We specialize in CNC turning service over 11 years of experience, our factory is located in Dongguan, Guangdong, China, near Shenzhen and Guangzhou. We have the confidence to become one of your long-term partners if you can give me a chance to service you. |

|

Machining |

Milling |

Turning |

|

Cnc Machining Tips

|

Cnc Milling Tool Offset

|

Cnc Turning Tool Holders

|

|

Cnc Machining Time Calculation

|

Cnc Milling Tool Holder

|

Cnc Turning Tool Holder Types

|

|

Cnc Machining Time Calculation Formula

|

Cnc Milling Tool Holder Types

|

Cnc Turning Tapping Program

|

Write your message here and send it to us