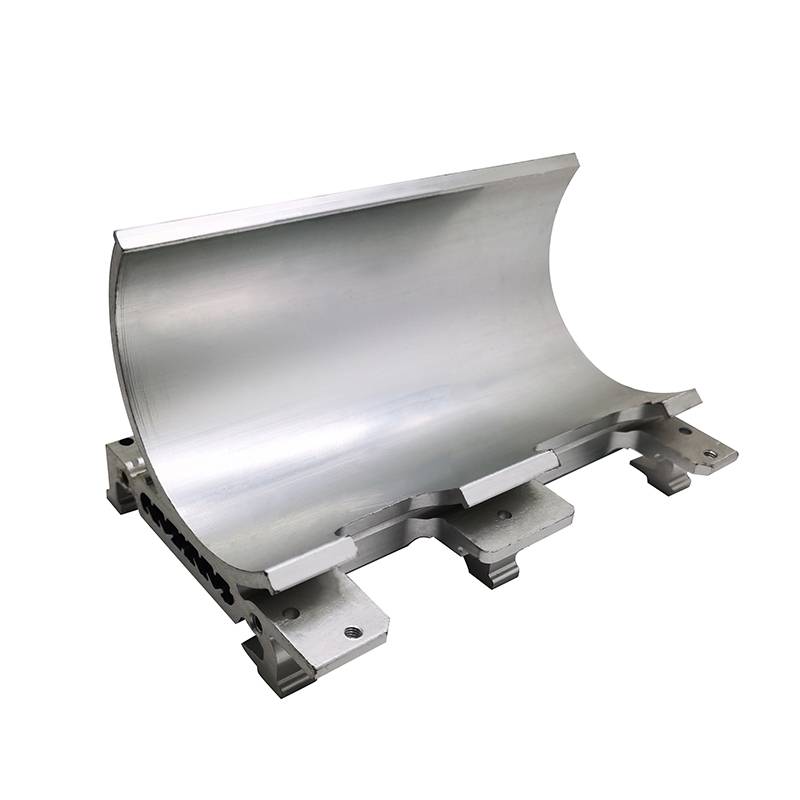

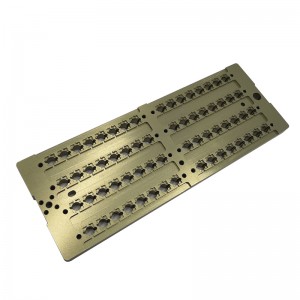

Axis Milling

CNC Milling classified by spindle position:

CNC vertical milling machine CNC vertical milling machine has occupied the majority of CNC milling machines in quantity, and the application range is also the widest. From the point of view of the number of coordinates of the CNC control of the machine tool, the current 3-axis CNC vertical milling still accounts for the majority; generally, 3 coordinate processing can be performed, but some machines can only perform coordinate processing of any two of the three coordinates ( Often referred to as 2.5 coordinate processing). In addition, there are four-coordinate and 5-coordinate NC vertical milling of the machine tool spindle for one or two axes of the X, Y, and Z axes.

Words:cnc milling service/ cnc precision milling/ high speed milling/ mill parts/ milling/ precision milling