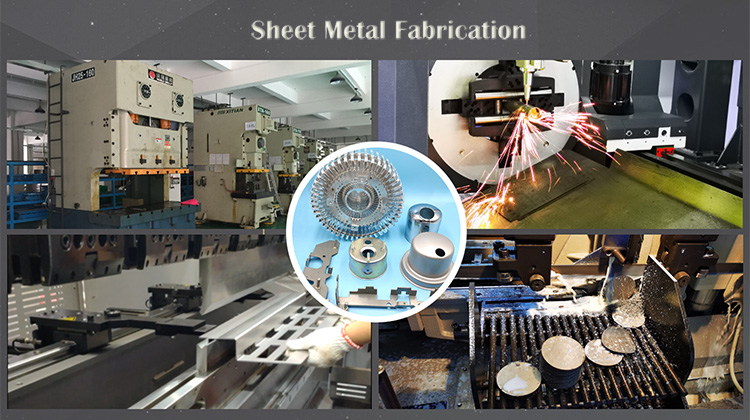

Best Metal Stamping Parts

We are able to provide high quality merchandise, competitive selling prices and the best customer support. For the custom precision deep-drawn metal stamping parts purchased by the factory, we adhere to the business philosophy of "customer first, forge ahead".

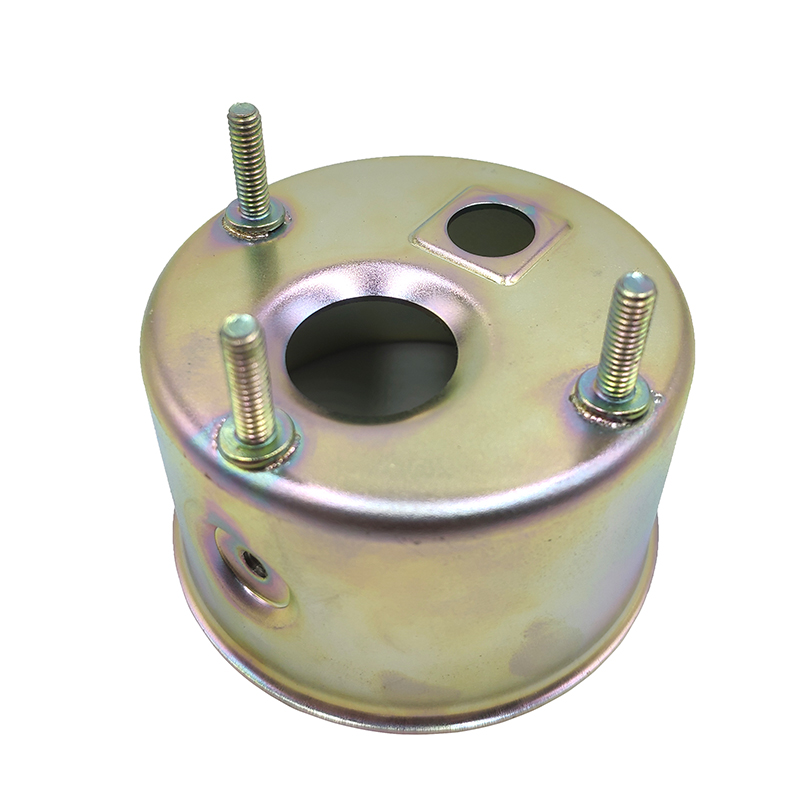

The factory's supply of deep-drawn stamping parts, deep-drawn stamping parts, stamping parts, and parts have passed the national qualification certification, and have been well received in our major industries. We care about every step of our service, from factory selection, product development and design, price negotiation, inspection, transportation to aftermarket. We have implemented a strict and complete quality control system to ensure that each product can meet the customer's quality requirements. Our professional engineering team is always available to provide you with advice and feedback.

|

cnc milling service |

custom cnc aluminum |

aluminum stamping |

|

custom cnc milling |

cnc turning service |

metal sheet stamping |

|

aluminum cnc milling service |

cnc turning services |

sheet metal stamping |