Cheapest Price Sheet Metal Manufacturing Process - Metal Stamping Parts Gasket – Anebon

Specifications:

1. High class metal material gasket 2. Professional work team

3. Good material gasket 4. OEM standard

Description:

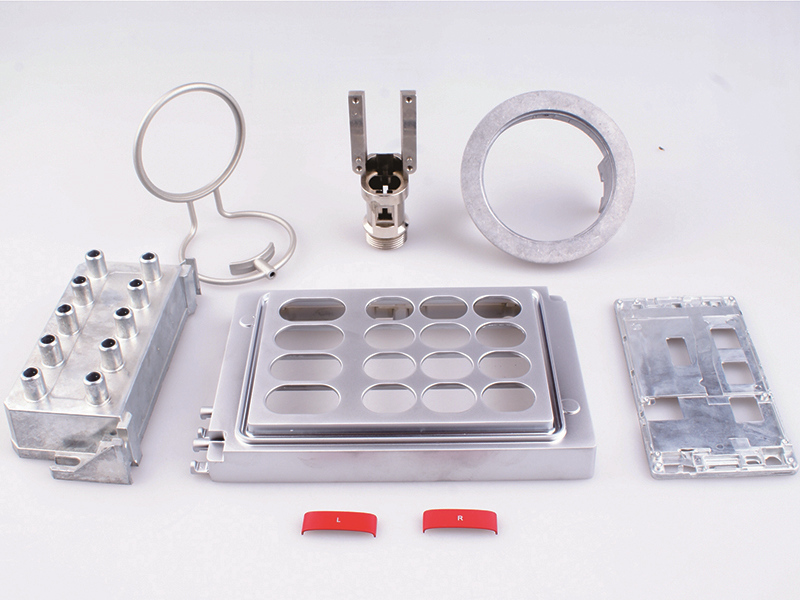

We can produce and process the stamping parts according to your any requirements of materials,

specifications, shapes, surfaces, packaging (and so on).

Equipment

1) Stamping Machine, Oil Hydraulic Pressing Machines, Riveting Machine, Welding Machine

2) CNC Milling and Turning, Grinding, Honing, Lapping, Broaching and other secondary Machining, Meter

Lathes

3) Line-cutting Machine, Laser-cutting Machine

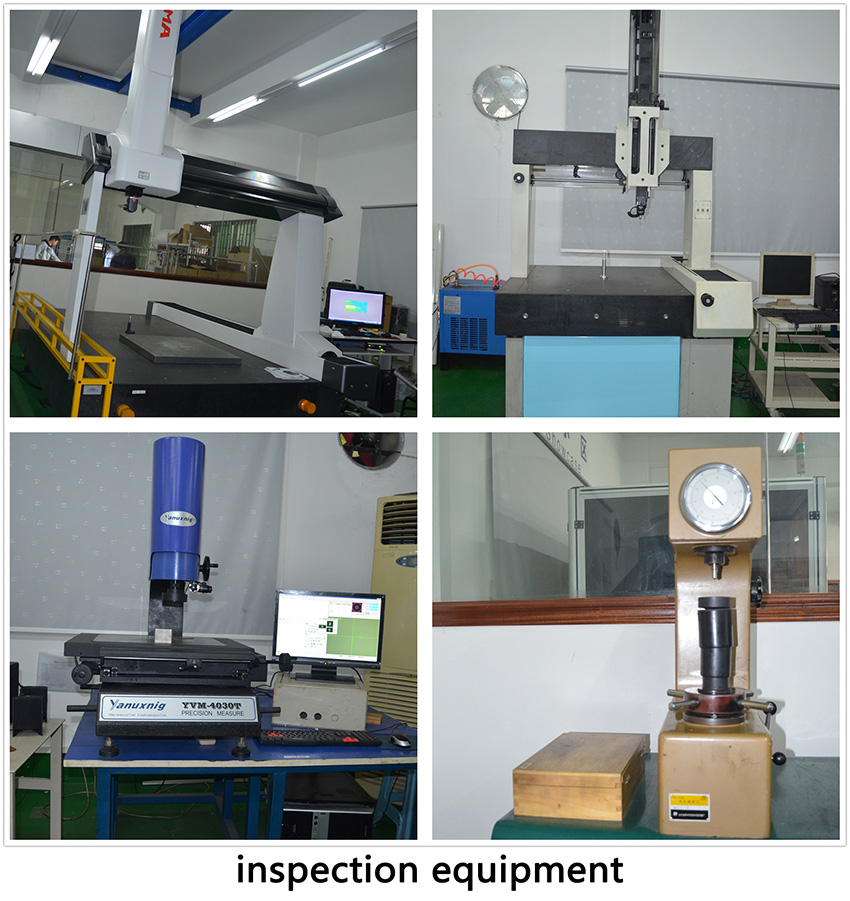

Test Equipment: Hardness tester, Chemical analysis, Digital Measuring Projector, Dynamic Balancing

Tester, Plating Tester

Material Available: Copper, Brass, Carbon Steel, Stainless Steel, Aluminum, Zinc, Bronze, Steel, etc.

Surface Treatment: Silver/Zinc/Nickel/Tin/Chrome Plating, Pickling, Powder Coating, Hot Galvanized,

Polishing, Brushing, etc.

Production Process: Laser/Line cutting, Stamping, CNC Punching, CNC Bending, Welding, Assembling

Standard: IEC ANSI API BS DIN JIS GB etc

R&D Capacity: Professional Tooling development & process & design

Inspection: IQC, IPQC, FQC, QA

Features: Customized Design, Small Order Allowed, Sample Product Available, Competitive Price

Delivery time: 7-30 days after get the deposit

Packing: Carton, Wooden Case, Pallet etc.

OUR PRODUCING PROCESS

1. Tooling (Mold) design and Manufacture.

2. Manufacture the parts according to the Stamping Machine.

3. Riveting, Welding or Screw tap according to Customer’s require.

4. After finish manufacture process we will test the parts by the Image measurement instrument, Caliper,

Angel Gage etc.

5. After make sure all the dimension can reach customer demand. We will make the surface treatment

process.

6. After finish surface treatment we will test all the parts by worker so that we can make sure the parts

which we sell is 100% qualified.

7. After finishing test, we will pack the parts by Vacuum Package Machine.

Applications:

Hardware Industry: Metal stamping molds and parts.

Automotive industry: all kinds of parts (stampings).

The construction industry: steel connectors and a variety of hardware accessories.

Transportation industry: Railway Turnout accessories and all kinds of rail transportation accessories.

Home decoration: furniture hardware such as connecting pieces, handles, household decorative

hardware such as a variety of pendants.

Electronics: Lug and Terminal and other metal connectors, chassis cabinets and instrument housing, and

other sheet metal products.

Solar energy: Solar aluminum bracket.

Other industries: sports equipment, accessories, wind Dust panels and metal crafts, such as bottle racks

and so on.

Quality Control

1. ISO approved.

2. Inspection at site.

3. Inspection before shipping.

4. Testing machine.