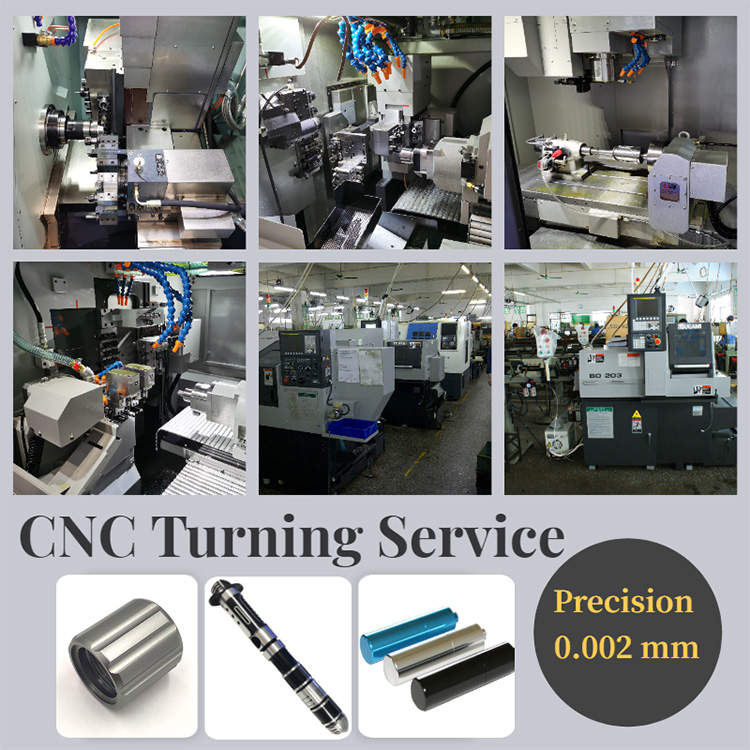

Precision Turned Components

The tool can be changed automatically during processing, so the processing efficiency is very high.You don't have to worry about the problem of not being able to deliver on time.

Words: cnc lathe process/ cnc lathe services/ cnc precision turning/ cnc turned components/ cnc turning/ turn services/ turned partslathe services

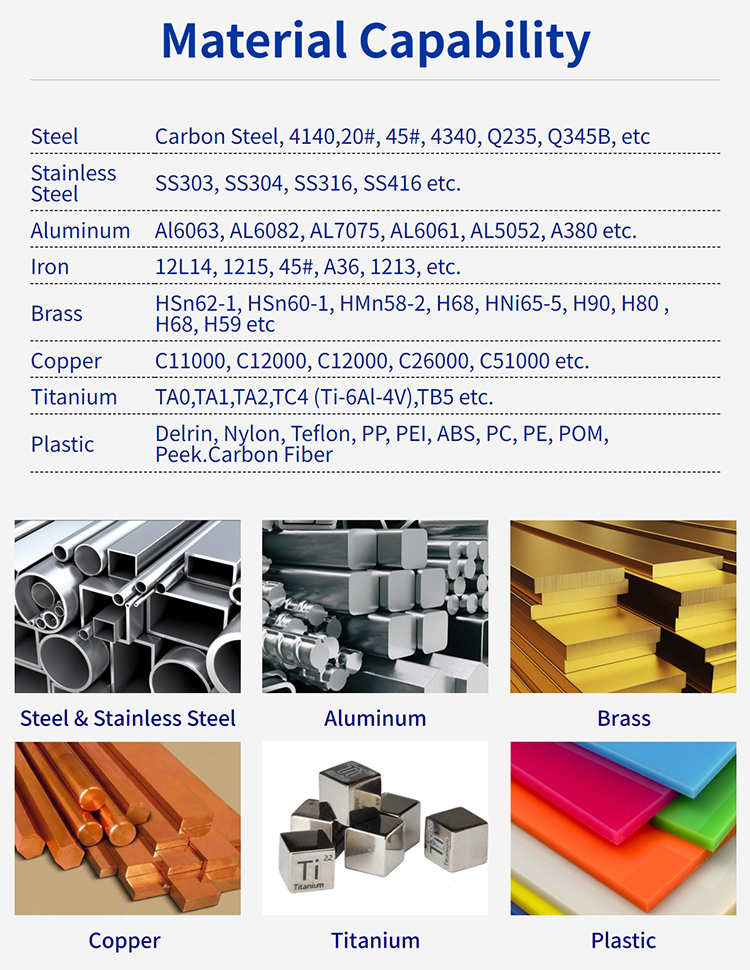

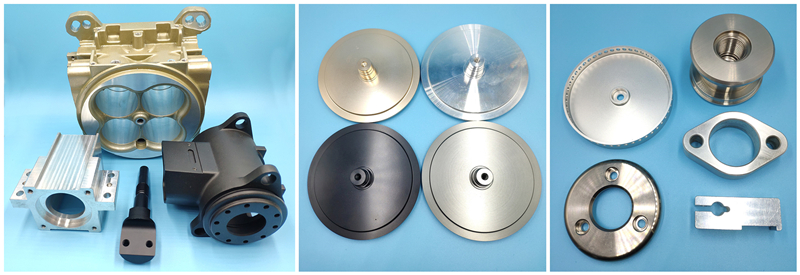

The products are processed in a wide range and reliable quality, covering clocks, electronics, automobiles, toys, communications, office supplies and other industries. Miscellaneous parts such as car parts and precision shafts, all kinds of products with length of 0.5MM-600MM can be processed. We can manufacture all kinds of fixtures, jigs, special knives, etc., excellent products and services, so that our products serve at home and abroad. A number of companies and industries have won the praise of our customers.

Advantage

• CNC processing equipment, powerful products, high quality, fast shipping

• Engineering R&D team with outstanding comprehensive strength and fast response

All kinds of drawing is acceptable.