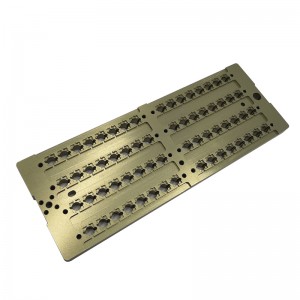

Custom Precision CNC Turning Milling

Because of our professionalism and maintenance awareness, our company has won the favor of consumers everywhere in the environment, and we believe that this makes us stand out from the competition and win customers' choice and trust in us.

Our products have earned an excellent reputation in every relevant country. Because our company was established. We have always insisted on our production process innovation and the latest modern management methods to attract a large number of talents in the industry. We believe that the good quality of the solution is our most important essence.

| Capabilities | CNC center machining, Milling, drilling, turning, grinding, tapping,

mould design and processing, casting, sheet metal working etc. |

Tolerances | +/-0.005mm------+/-0.02mm |

| Secondary Operations | Bending, Brazing, Cross Drilling, Grinding, Knurling, Laser Cutting, Milling,

Slotting, Surface Grinding, Tapping, Threading, Ultrasonic Welding, |

Finishing Services | Anodizing Bead Blasting Hard Coat Anodizing Heat-treating Induction Heat Treating Laser Etching Pad Printing Painting Parkerizing Plating Polishing Powder Coating Precious Metal Plating |

| Other Services | Assembly, Cam Design, Cam Making, Design Assistance ,Inspection, Packaging,

Rapid Prototyping, Reverse Engineering, Tool Design, Tool Grinding, |

Applications | Fasteners, Housings, Inserts, Pinions, Pins, Pistons, Shafts, etc. |

| Industries Served | Aerospace, Automotive, Electronics, Medical, Oil and Gas, | Professional Associations | China Hardware Processing Alliance, Precision Machined Products Association, CNC processing association, Aluminum Custom Precision Cheap CNC Parts |

| cnc micro machining | cnc plastic | cnc steel |

| rapid precision machining | cnc plastic parts | cnc watch parts |

| 5 axis machining center | cnc process | copper and brass fittings |