Die Casting Part With Aluminum

Our Services:

1. Provide customized Sevice: could make product for customer according to customer samples or drawings.

2. Can deal with various drawings soft wares: PRO/E, Auto CAD, Slid Work, UG, etc

3. Could offer samples for free .

4. Submit samples with official inspection reports including Material chemical compsition report, Mechanical Property report and dimensional report.

5.We could supply storage service for customer if required.

6. Lead time: 20days for samples, 30days for production.

Packaging Information:

1. Put light oil onto product.

2. VCI packaging is available with desiccant.

3. Pack product individually by bubble bag or Foam packaging.

4. Good quality carton pack by Grade A carton, each carton is no more than 35lbs.

5. Pallet or wooden case.

Why Choose Us?

1. We are a direct manufacturer have 16 years experience in aluminum die casting with very low piece price.

2. All kinds of surface treatments are available: Polishing, zinc plating, nickel plating, powder coating, e-coating, DIP coating, phosphate coating, anodizing, painting, etc.

3. We can provide fabrication, deep drawing, machining, welding and assembly.

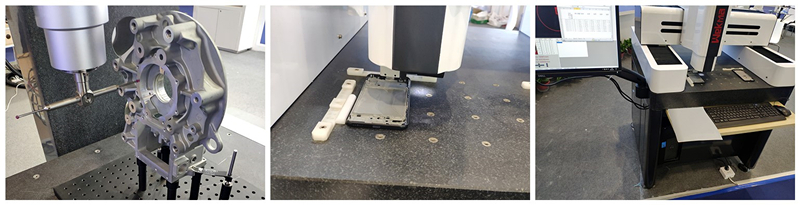

4. Roviding samples with inportant dimensions and customizing inspection report, material certification to customer for validation and verification.

5. We offer unique solutions to your profucts with reasonable price, good quality and best service.

6. We specialize in fast turn around with low volume orders. Please forward your specification for quoting.