Wannan shi ne taƙaitaccen mutanen da ke cikin masana'antu lokacin da aka taƙaita ƙirar ƙirar, amma yana da nisa daga sauƙi.A cikin tsarin tuntuɓar tsare-tsare daban-daban, mun gano cewa koyaushe akwai wasu matsalolin matsawa da matsawa a cikin ƙirar farko.Ta wannan hanyar, duk wani sabon tsari zai rasa mahimmancinsa.Ta hanyar fahimtar ainihin ilimin sakawa da ɗaurewa kawai za mu iya tabbatar da amincin ƙirar ƙira da tsarin sarrafawa.

Ilimin wuri

1. Basic manufa na sakawa daga gefen workpiece

Lokacin da aka sanyawa daga gefen aikin aikin, ka'idar ma'auni uku ita ce mafi mahimmancin ka'ida, kamar yadda goyon baya.Wannan daidai yake da ka'idar goyon baya, wanda ake kira ka'idar ma'auni uku, wanda aka samo daga ka'idar "maki uku ba a kan layi daya suna ƙayyade jirgin sama ba".Uku daga cikin maki hudu na iya tantance fuska, don haka ana iya tantance jimlar fuskoki hudu.Duk da haka, ko ta yaya za a gano, yana da wuya a sami maki na huɗu a cikin jirgin guda ɗaya.

▲ Ka'ida ta uku

Misali, lokacin amfani da madaidaicin madaidaicin tsayi 4, maki 3 kawai a wuri ɗaya na iya tuntuɓar kayan aikin, kuma sauran maki 4 har yanzu suna da yuwuwar tuntuɓar kayan aikin.

Don haka, lokacin da ake daidaita ma'aunin wuri, gabaɗaya yana dogara ne akan maki uku, kuma ya kamata a ƙara nisa tsakanin waɗannan maki uku gwargwadon yiwuwa.

Bugu da ƙari, lokacin saita matsayi, wajibi ne don tabbatar da jagorancin nauyin aikin da aka yi amfani da shi a gaba.Jagoran nauyin sarrafawa kuma shine jagorancin kayan aiki / kayan aiki na tafiya.An saita mai sakawa a ƙarshen jagorar ciyarwa, wanda zai iya tasiri kai tsaye gabaɗayan daidaiton aikin aikin.

Gabaɗaya, ana amfani da nau'in nau'in aron ƙarfe daidaitacce positioner don sakawa blank surface na workpiece, da tsayayyen nau'in (daCNC Juya Sassanlamba surface ne kasa) positioner da ake amfani da sakawa da machining surface na workpiece.

2. Basic manufa na sakawa daga workpiece rami

Lokacin amfani da rami da aka sarrafa a cikin tsarin da ya gabata na workpiece don sakawa, dole ne a yi amfani da fil ɗin haƙuri don sakawa.Ta hanyar daidaita daidaiton ramin aikin aiki tare da daidaiton bayanin martabar fil da haɗawa gwargwadon haƙurin dacewa, daidaiton matsayi na iya saduwa da ainihin buƙatun.

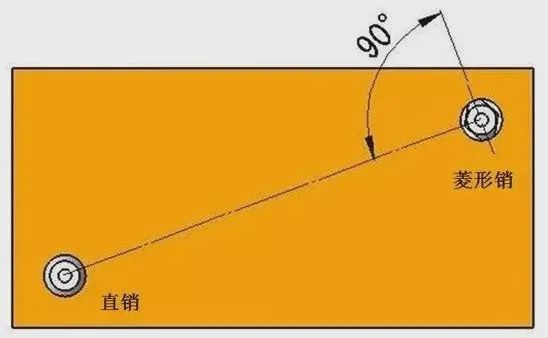

Bugu da kari, lokacin amfani da fil don sakawa, gabaɗaya ɗaya yana amfani da madaidaicin fil ɗaya kuma yana amfani da fil ɗin lu'u-lu'u, don haka zai fi dacewa don haɗawa da kwakkwance kayan aikin.Yana da wuya aikin aikin ya makale da fil.

▲ Matsayi da fil

Tabbas, yana yiwuwa kuma a yi amfani da madaidaiciyar fil don duka fil biyu ta hanyar daidaita juriyar dacewa.Don ƙarin daidaiton matsayi, yawanci yana da inganci don amfani da madaidaicin fil da fil ɗin lu'u-lu'u.

Lokacin da ake amfani da madaidaicin fil da fil ɗin lu'u-lu'u, layin haɗin kai a cikin jagorar daidaitawa (inda fil ɗin lu'u-lu'u ya haɗu da aikin aikin) na fil lu'u-lu'u yawanci 90 ° daidai da layin haɗin tsakanin madaidaiciya fil da fil ɗin lu'u-lu'u.Wannan saitin shine don matsayi na kusurwa (madaidaicin juyawa na workpiece).

Ilimin da ya dace na manne

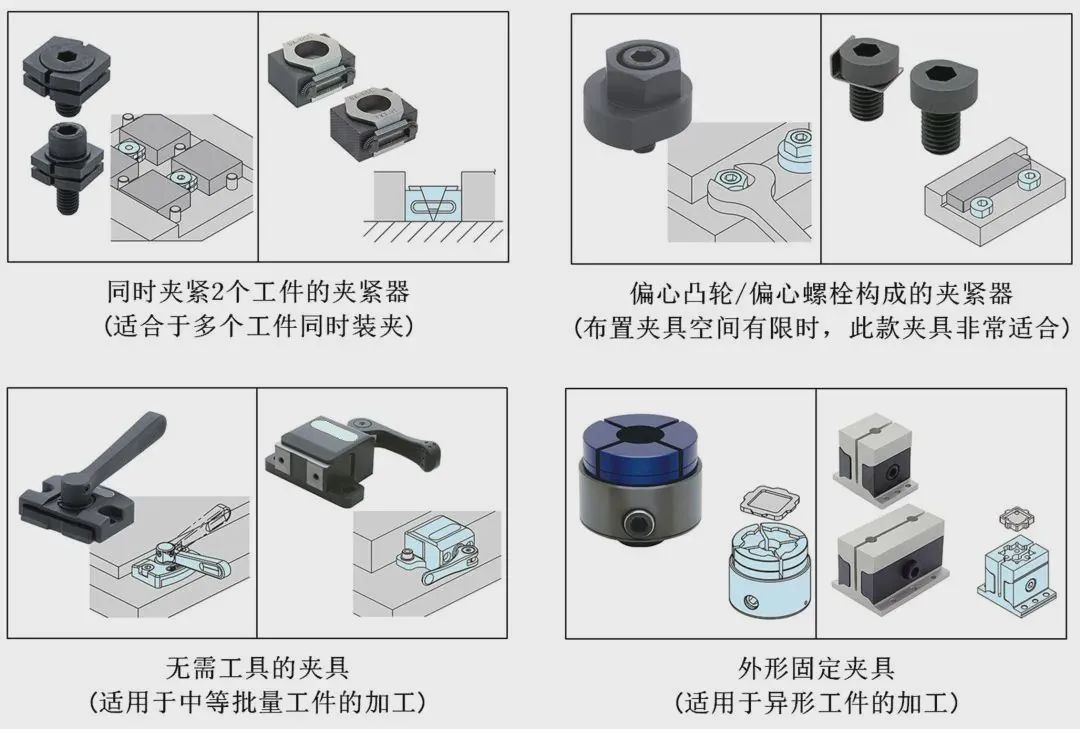

1. Rarrabewa na grippers

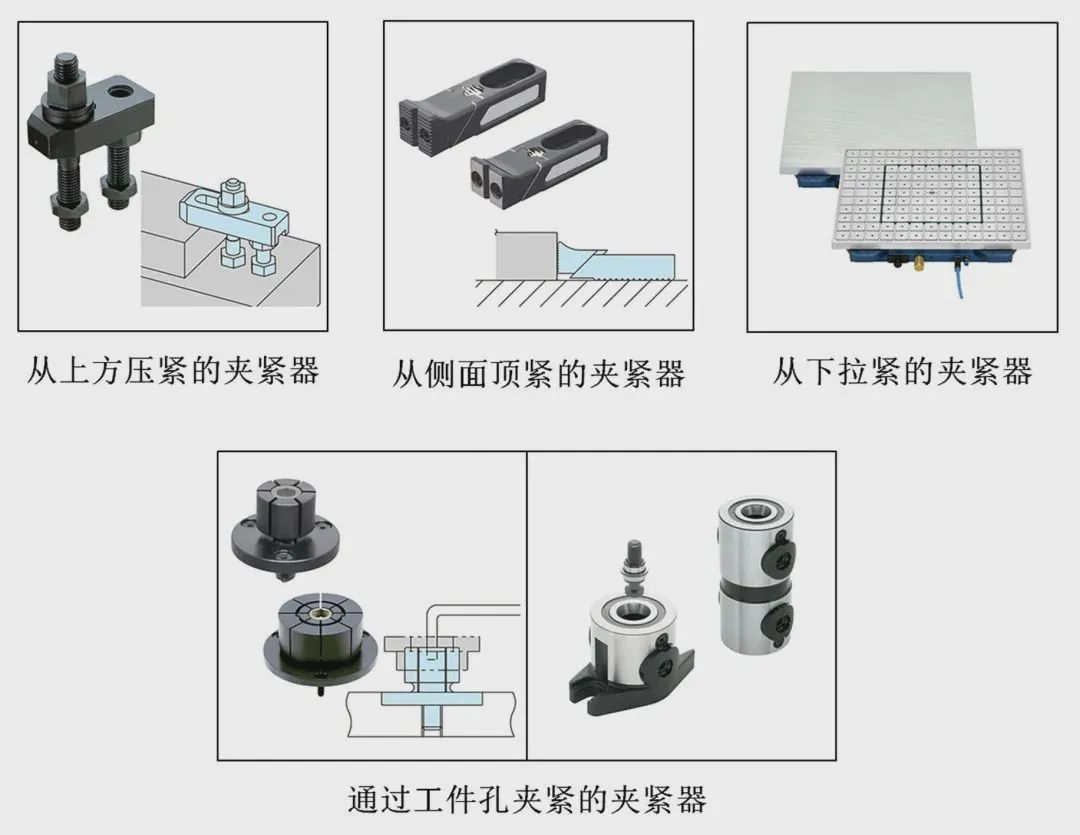

Dangane da jagorar matsawa, gabaɗaya an raba shi zuwa rukuni masu zuwa:

Gaba, bari mu dubi halaye na daban-daban clamps.

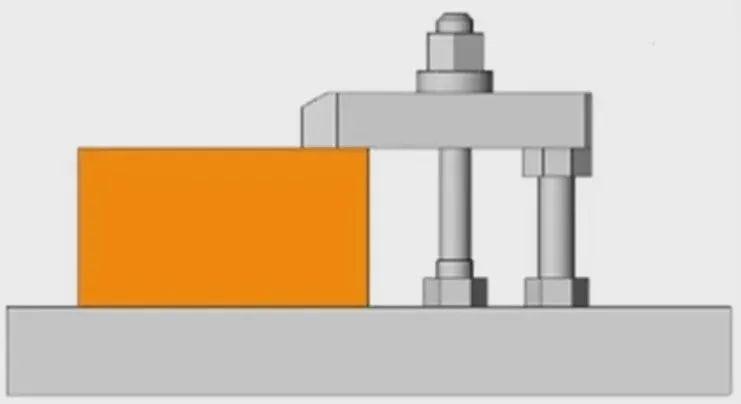

1. Matsala daga sama

Na'urar matsawa da aka danna daga saman kayan aikin tana da mafi ƙarancin nakasu yayin matsewa, kuma ita ce mafi kwanciyar hankali yayin sarrafa kayan aikin.Sabili da haka, gabaɗaya, la'akari na farko shine don matsawa daga saman kayan aikin.Mafi na kowa kayan aiki don latsawa daga sama kayan aiki shine kayan aikin injina na hannu.Misali, siffa mai zuwa ana kiranta “nau’in leaf mai sako-sako”.Matsi da aka haɗe ta hanyar latsa farantin karfe, sandar ingarma, jack da goro ana kiranta matsi "leaf sako-sako".

Bugu da ƙari, ana iya zaɓar faranti tare da siffofi daban-daban bisa ga siffar aikin aiki.KamarCNC Machining Parts, Juya Sassan da Niƙa Sassan.

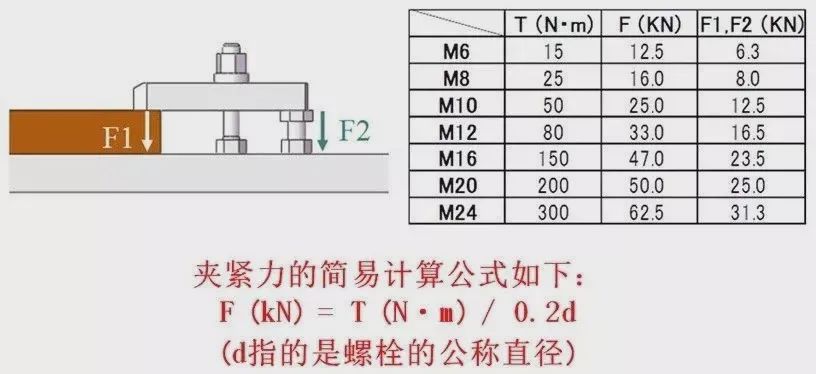

Dangantakar da ke tsakanin jujjuyawar juzu'i da matsewar nau'in nau'in nau'in ganye mara kyau ana iya ƙididdige shi ta hanyar turawa na aron.

Baya ga matse ganyen da ba a kwance ba, ana samun nau'ikan matsi iri ɗaya masu zuwa don matsawa daga saman kayan aikin.

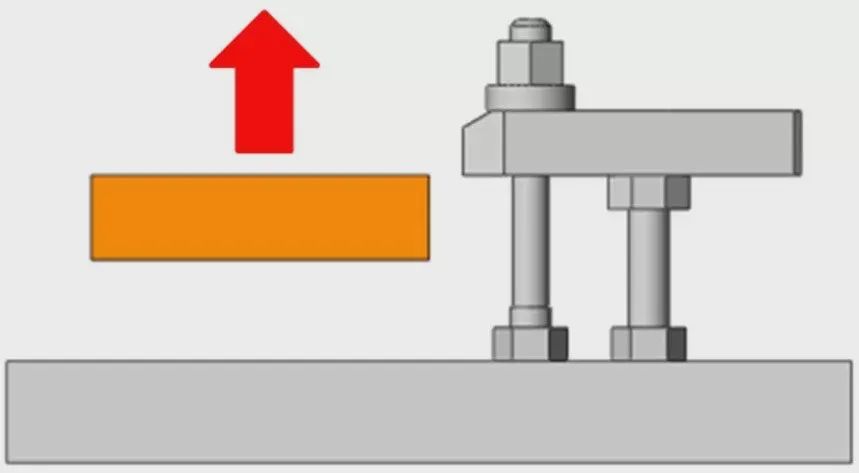

2. Matsa matse daga gefe

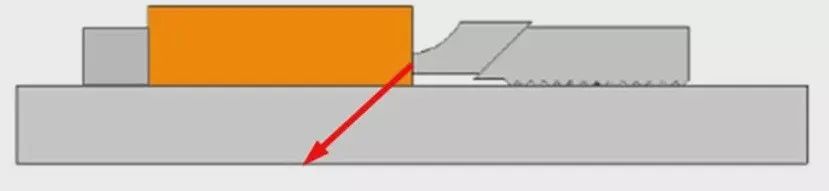

Asali, hanyar ƙwanƙwasa kayan aiki daga sama shine mafi kwanciyar hankali da daidaito kuma mafi ƙarancin sarrafa kayan aikin.Duk da haka, lokacin da ya zama dole don aiwatar da aiki a sama da kayan aiki, ko kuma bai dace ba don matsawa daga sama da kayan aiki, wanda ya sa ba zai yiwu ba daga sama da kayan aiki, za ka iya zaɓar don matsawa daga gefen aikin.Duk da haka, in mun gwada da magana, lokacin da workpiece aka clamped daga gefe, shi zai samar da wani iyo da karfi.Yadda za a kawar da wannan karfi dole ne a kula da shi lokacin zayyana kayan aiki.

Kamar yadda aka nuna a cikin hoton da ke sama, matsi na gefe shima yana da ƙarfin da ba a taɓa gani ba yayin samar da tuƙi, wanda zai iya hana aikin aikin daga iyo sama yadda ya kamata.

Matsakan da ke manne daga gefe suma suna da manne makamancin haka.

3. Clamping na'urar ga tightening workpiece daga ja-saukar

A lokacin da machining na sama surface na bakin ciki farantin workpiece, shi ne ba kawai ba zai yiwu ba don matsa shi daga sama, amma kuma m damfara shi daga gefe.Hanya madaidaiciya madaidaiciya ita ce ta ƙarfafa aikin aikin daga ƙasa.Lokacin da workpiece ne tensioned daga kasa, idan an yi shi da baƙin ƙarfe, da wani maganadisu manne yawanci za a iya amfani da.Don kayan aikin ƙarfe mara ƙarfe, za a iya amfani da kofuna na tsotsa gabaɗaya don tayar da hankali.

A cikin shari'o'i biyun da ke sama, ƙarfin matsawa ya yi daidai da wurin tuntuɓar da ke tsakanin kayan aiki da maganadisu ko vacuum chuck.Idan nauyin sarrafawa ya yi girma yayin sarrafa ƙananan kayan aiki, tasirin sarrafawa ba zai zama mai kyau ba.

Bugu da kari, lokacin amfani da maganadisu ko vacuum suckers, wuraren tuntuɓar masu magana da maganadisu da injin tsotsa suna buƙatar sanya su zuwa wani matakin santsi kafin a yi amfani da su cikin aminci da al'ada.

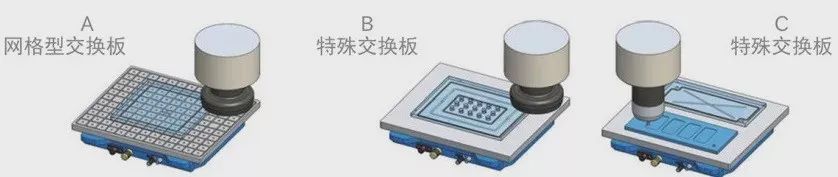

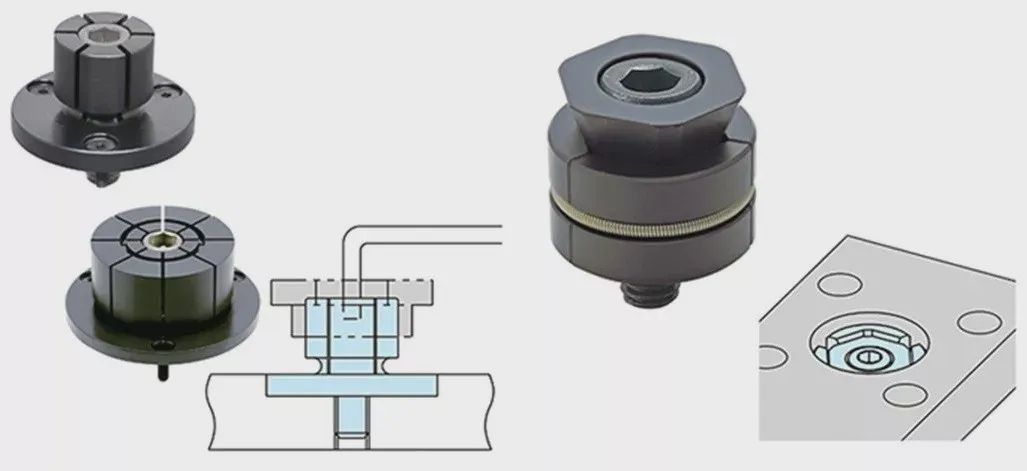

4. Na'urar matsawa tare da ramuka

Lokacin amfani da injin injin 5-axis don aiwatar da fuskoki da yawa a lokaci guda ko sarrafa gyare-gyare, don hana tasirin kayan aiki da kayan aiki akan sarrafawa, gabaɗaya ya dace a yi amfani da hanyar ƙulla rami.Idan aka kwatanta da hanyar clamping daga sama da gefen aikin aikin, hanyar ƙulla rami yana da ƙarancin nauyi akan kayan aikin kuma yana iya lalata aikin aikin yadda ya kamata.

▲ Gudanar da kai tsaye tare da ramuka

▲ Saita rivet don matsawa

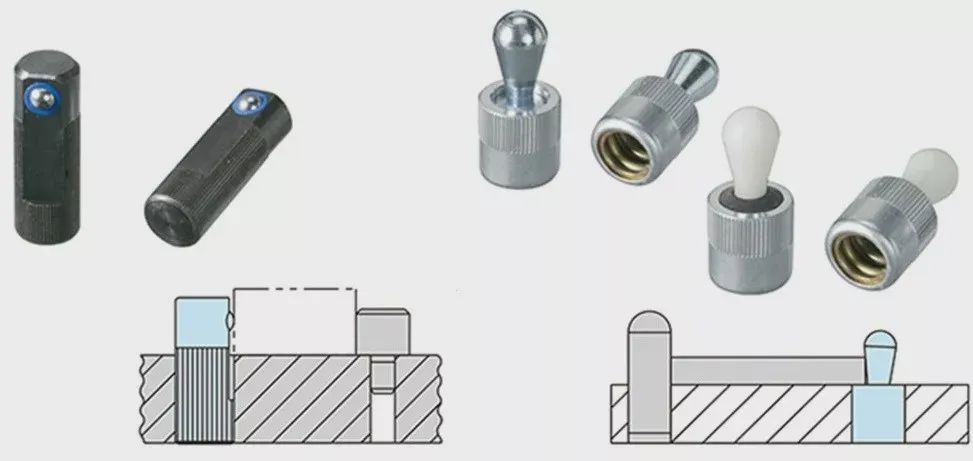

2. Pre clamping

Abubuwan da ke sama musamman game da clamping fixture na workpiece.Yadda ake haɓaka aiki da amfani da pre clamping shima yana da mahimmanci.Lokacin da workpiece aka kafa a tsaye a kan tushe, da workpiece zai fadi saboda nauyi.A wannan lokacin, dole ne a yi amfani da gripper yayin riƙe da kayan aiki da hannu.

▲ Pre clamping

Idan kayan aikin sun yi nauyi ko kuma yawancinsu an matse su a lokaci guda, aikin zai ragu sosai kuma lokacin matsawa zai yi tsayi sosai.A wannan lokacin, amfani da wannan samfurin pre clamping nau'in bazara na iya ba da damar aikin aikin don yin aiki da gripper a cikin wani tsayayyen yanayi, yana haɓaka aiki sosai da rage lokacin clamping na workpiece.

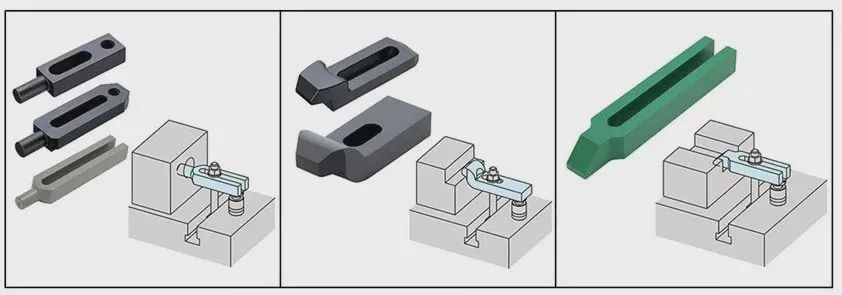

3. Tsare-tsare yayin zabar gripper

Lokacin da aka yi amfani da nau'ikan manne da yawa a cikin kayan aiki iri ɗaya, kayan aikin matsewa da sassautawa dole ne a haɗa su.Misali, kamar yadda aka nuna a cikin adadi na hagu, lokacin amfani da kayan aiki iri-iri don aiki tare, nauyin mai aiki gabaɗaya zai zama mafi girma, kuma jimlar lokacin clamping na workpiece shima zai yi tsayi.Misali, a cikin hoton da ke hannun dama na ƙasa, maƙallan kayan aiki da girman kusoshi sun haɗu don sauƙaƙe masu aikin filin.

v Workpiece clamping operability

Bugu da kari, a lokacin da saita gripper, shi wajibi ne don la'akari da operability na workpiece clamping kamar yadda zai yiwu.Idan aikin aikin yana buƙatar karkatar da shi yayin clamping, aikin ba shi da daɗi sosai.Wannan yanayin yana buƙatar kaucewa lokacin da za a tsara kayan aiki.

Lokacin aikawa: Oktoba-24-2022