Lub fixture tsim feem ntau yog ua raws li cov kev cai ntawm ib tug tej yam txheej txheem tom qab lub machining txheej txheem ntawm qhov chaw yog formulated.Hauv kev tsim cov txheej txheem thev naus laus zis, qhov muaj peev xwm ntawm fixture realization yuav tsum tau txiav txim siab tag nrho, thiab thaum tsim lub fixture, nws muaj peev xwm tawm tswv yim hloov kho rau cov txheej txheem thev naus laus zis yog tias tsim nyog.Kev tsim cov cuab yeej siv tau zoo yuav tsum ntsuas los ntawm seb nws puas tuaj yeem lav qhov kev ua haujlwm zoo ntawm cov khoom ua haujlwm, kev ua haujlwm siab, tus nqi qis, yooj yim tshem tawm nti, kev ua haujlwm nyab xeeb, kev txuag hluav taws xob, kev tsim khoom yooj yim, thiab kev saib xyuas yooj yim.

1. Lub hauv paus ntsiab lus ntawm fixture tsim

1. Txaus siab rau kev ruaj ntseg thiab kev cia siab ntawm workpiece positioning thaum siv;

2. Muaj txaus load bearing los yog clamping quab yuam los xyuas kom meej cov kev ua ntawm lub workpiece ntawm lub fixture;

3. Txaus siab rau kev ua haujlwm yooj yim thiab nrawm hauv cov txheej txheem clamping;

4. Cov khoom tawg yooj yim yuav tsum yog cov qauv uas tuaj yeem hloov tau sai, thiab nws yog qhov zoo tshaj plaws kom tsis txhob siv lwm yam cuab yeej thaum cov xwm txheej txaus;

5. Txaus siab rau qhov kev cia siab ntawm qhov rov ua qhov chaw ntawm lub fixture thaum hloov lossis hloov;

6. Zam cov qauv tsim thiab cov nqi siab kom ntau li ntau tau;

7. Xaiv cov khoom siv raws li cov khoom sib xyaw kom ntau li ntau tau;

8. Tsim lub systemization thiab standardization ntawm lub tuam txhab cov khoom sab hauv.

2. Kev paub yooj yim ntawm kev tsim kho

Lub tshuab cuab yeej zoo fixture yuav tsum ua tau raws li cov hauv qab no:

1. Xyuas kom meej machining qhov tseeb ntawm lub workpiece.Tus yuam sij kom ntseeg tau qhov tseeb ntawm machining yog kom raug xaiv qhov chaw datum, txoj kev muab tso rau thiab cov khoom siv.Yog tias tsim nyog, kev txheeb xyuas qhov yuam kev yog qhov yuav tsum tau ua.Tsis tas li ntawd xyuam xim rau cov qauv ntawm lwm qhov chaw nyob rau hauv lub fixture rau lub machining raug Lub cawv ntawm qhov no los xyuas kom meej tias lub fixture yuav ua tau raws li lub machining qhov yuav tsum tau ntawm lub workpiece.

2. Qhov nyuaj ntawm qhov tshwj xeeb fixture rau kev txhim kho ntau lawm efficiency yuav tsum tau yoog raws li lub peev xwm ntau lawm.Ntau yam ceev thiab zoo clamping mechanisms yuav tsum tau saws kom deb li deb tau los xyuas kom meej lub lag luam yooj yim, txo lub sij hawm pab, thiab txhim kho ntau lawm efficiency.

3. Cov qauv ntawm qhov tshwj xeeb fixture nrog cov txheej txheem kev ua tau zoo yuav tsum yog qhov yooj yim thiab tsim nyog, uas yooj yim rau kev tsim khoom, sib dhos, hloov kho, tshuaj xyuas, tu, thiab lwm yam.

4. Kev siv tau zoo.Lub fixture yuav tsum muaj lub zog txaus thiab rigidity, thiab kev ua haujlwm yuav tsum yooj yim, txuag zog, nyab xeeb thiab txhim khu kev qha.Raws li qhov kev pom zoo tias lub hom phiaj tau tso cai thiab muaj kev lag luam thiab siv tau, pneumatic, hydraulic thiab lwm yam khoom siv clamping yuav tsum tau siv ntau npaum li qhov ua tau los txo qis kev siv zog ntawm tus neeg teb xov tooj.Tooling fixtures kuj tseem yuav yooj yim rau kev tshem tawm nti.Thaum tsim nyog, cov txheej txheem tshem tawm cov nti tuaj yeem raug teeb tsa los tiv thaiv cov chips los ntawm kev puas tsuaj ntawm qhov chaw ua haujlwm thiab ua rau lub cuab yeej ua kom tsis zoo, thiab tiv thaiv cov khoom ntawm cov chips los ntawm kev nqa cov cua sov ntau thiab ua rau deformation ntawm cov txheej txheem.

5. Qhov tshwj xeeb fixture nrog kev lag luam zoo yuav tsum tau txais cov qauv tsim thiab cov qauv tsim kom ntau li ntau tau, thiab siv zog ua kom yooj yim hauv cov qauv thiab yooj yim rau kev tsim khoom, thiaj li txo cov nqi tsim khoom ntawm lub fixture.Yog li ntawd, qhov tsim nyog technical thiab economic tsom xam ntawm lub fixture lub hom phiaj yuav tsum tau ua raws li qhov kev txiav txim thiab muaj peev xwm ntau lawm thaum lub sij hawm tsim los txhim kho lub economic efficiency ntawm fixture nyob rau hauv ntau lawm.aluminium qhov

3. Txheej txheem cej luam ntawm standardization ntawm tooling thiab fixture tsim

1. Cov txheej txheem thiab cov kauj ruam ntawm kev tsim kho

Kev npaj ua ntej tsim.Cov ntaub ntawv qub ntawm kev siv cuab yeej thiab kev tsim kho fixture muaj xws li hauv qab no:

a) Cov ntawv ceeb toom tsim, cov khoom tiav tiav, kos duab kos duab thiab cov txheej txheem kev ua haujlwm thiab lwm yam khoom siv, nkag siab txog cov txheej txheem kev ua haujlwm ntawm txhua tus txheej txheem, qhov chaw thiab clamping schemes, cov ntsiab lus ntawm cov txheej txheem dhau los, cov xwm txheej ntawm qhov khoob, cov cuab yeej siv tshuab thiab cov cuab yeej siv hauv kev ua, Kev tshuaj xyuas cov cuab yeej ntsuas, cov nyiaj siv ua haujlwm thiab txiav nyiaj, thiab lwm yam .;

b) Nkag siab txog cov khoom tsim khoom thiab qhov kev thov rau cov khoom siv;

c) Nkag siab txog cov ntsiab lus tseem ceeb, kev ua haujlwm, kev qhia tshwj xeeb, qhov tseeb ntawm cov cuab yeej siv lub tshuab siv, thiab qhov sib txuas loj ntawm cov qauv ntawm qhov kev sib txuas nrog lub fixture, thiab lwm yam;

d) Cov khoom siv raw khoom ntawm cov khoom siv.cnc machining hlau qhov

2. Cov teeb meem suav nrog hauv kev tsim cov khoom siv

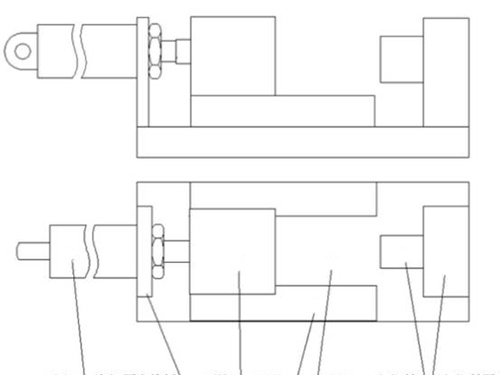

Lub fixture tsim feem ntau muaj ib tug qauv, uas ua rau tib neeg xav tias tus qauv tsis nyuaj heev, tshwj xeeb tshaj yog tam sim no hais tias qhov nrov ntawm hydraulic fixtures zoo heev simplifies tus thawj mechanical qauv, tab sis yog hais tias tus txheej txheem tsim tsis xav nyob rau hauv kom meej, tsis tsim nyog teeb meem. yuav inevitably tshwm sim:

a) Qhov khoob khoob khoob ntawm qhov chaw ua haujlwm.Qhov luaj li cas ntawm qhov khoob yog loj heev thiab cuam tshuam tshwm sim.Yog li ntawd, daim duab ntxhib yuav tsum tau npaj ua ntej tsim.Cia qhov chaw txaus.

b) Unblocked nti tshem tawm ntawm lub fixture.Vim qhov chaw ua haujlwm tsawg ntawm cov cuab yeej siv lub tshuab thaum lub sij hawm tsim, lub fixture feem ntau yog tsim los kom compact.Nyob rau lub sijhawm no, nws feem ntau tsis quav ntsej tias cov ntaub ntawv hlau tsim tawm thaum lub sijhawm ua cov txheej txheem yog khaws cia rau hauv qhov chaw tuag ntawm cov khoom siv, suav nrog cov dej tsis zoo ntawm cov kua nti, uas yuav ua rau kev ua haujlwm yav tom ntej coj teeb meem ntau.Yog li ntawd, thaum pib ntawm qhov teeb meem tiag tiag, peb yuav tsum xav txog cov teeb meem hauv kev ua haujlwm.Tom qab tag nrho, lub fixture yog raws li kev txhim kho efficiency thiab yooj yim ua hauj lwm.

c) Tag nrho qhov qhib ntawm lub fixture.Tsis quav ntsej qhov qhib ua rau nws nyuaj rau tus neeg teb xov tooj rau nruab daim npav, siv sijhawm ntev thiab siv zog, thiab tsim kev txwv.

d) Lub hauv paus ntsiab lus theoretical ntawm fixture tsim.Txhua qhov kev sib tw yuav tsum tau ua ntau yam clamping thiab loosening, yog li nws tuaj yeem ua tau raws li cov neeg siv khoom xav tau thaum pib, tab sis lub fixture yuav tsum muaj nws qhov tseeb tuav, yog li tsis txhob tsim ib yam dab tsi uas tsis sib haum nrog lub hauv paus ntsiab lus.Txawm hais tias koj muaj hmoo tam sim no, yuav tsis muaj kev ruaj ntseg mus ntev.Ib tug zoo tsim yuav tsum sawv ntawm temper ntawm lub sij hawm.

e) Replaceability ntawm positioning Cheebtsam.Cov khoom siv ntawm qhov chaw yog hnyav hnyav, yog li kev hloov pauv sai thiab yooj yim yuav tsum tau xav txog.Nws yog qhov zoo tshaj kom tsis txhob tsim rau hauv qhov loj.

Kev sib sau ntawm kev tsim kho fixture yog qhov tseem ceeb heev.Qee zaum kev tsim qauv yog ib yam, tab sis nws yog lwm yam hauv kev siv tswv yim, yog li kev tsim qauv zoo yog cov txheej txheem ntawm kev sib sau ua ke thiab kev sib sau ua ke.

Feem ntau siv fixtures feem ntau muab faib ua hom hauv qab no raws li lawv cov functionality:

01 clamp

02 Drilling thiabmilling cuab yeej

03 CNC, ntsuas chuck

04 Gas and water test tooling

05 Trimming thiab xuas nrig ntaus tooling

06 vuam tooling

07 Polishing fixture

08 Cov cuab yeej sib dhos

09 Pad printing, laser engraving tooling

Anebon Hlau Khoom Limited tuaj yeem muab CNC Machining, Tuag Casting, Sheet Hlau Fabrication kev pabcuam, thov koj xav tiv tauj peb.

Tel: +86-769-89802722 E-mail: info@anebon.com URL: www.anebon.com

Post lub sij hawm: Mar-29-2021