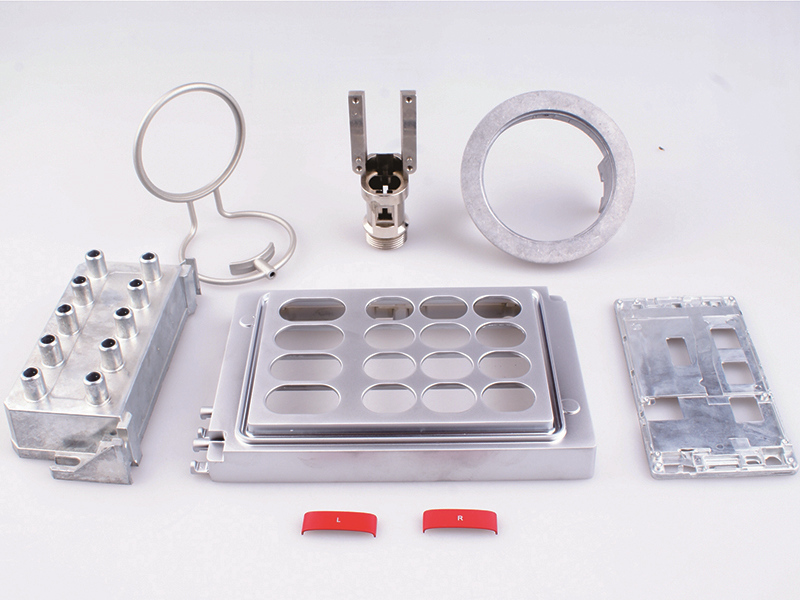

Metal Stamping Part

The stamping part is a production technology of a product part which is deformed by a deformation force in a mold by means of power of a conventional or special stamping apparatus, thereby obtaining a shape, a size and a performance. Sheets, molds and equipment are the three elements of stamping. Stamping is a method of cold deformation of metal. Therefore, it is called cold stamping or sheet stamping, referred to as stamping. It is one of the main methods of metal plastic processing (or pressure processing) and is also part of material forming engineering technology.

Words:Metal stamping part/ Metal stamping parts/ aluminium stamping/ Steel Stamping Parts/ all metal stamping/ aluminum stamping

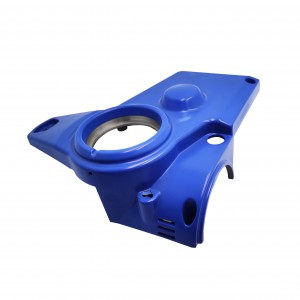

CNC milling plastic parts custom precision machining prototypes

| Service | CNC MachiningTurning and MillingLaser CuttingOEM Parts |

| Material | 1). Aluminum\Aluminum alloy 2). Steel\Stainless steel 3). Copper\Brass 4). Plastic 5).Die casting CNC |

| Finish | Sandblasting, Anodize color, Blackenning, Zinc/Nickl Plating, Polish, etc. |

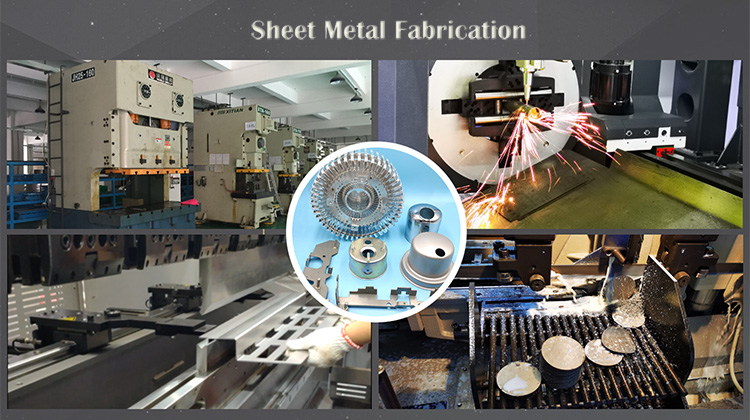

| Main Equipment | CNC Machining center(Milling), CNC Lathe, Grinding machine, Cylindrical grinder machine, Drilling machine, Laser Cutting Machine,etc. |