Milling process

Processing Equipments: cnc machining center, cnc lathe, grinding machine, automatic lathe machine, conventional lathe machine, milling machine, drilling machine, EDM, wire-cutting machine, CNC bending.

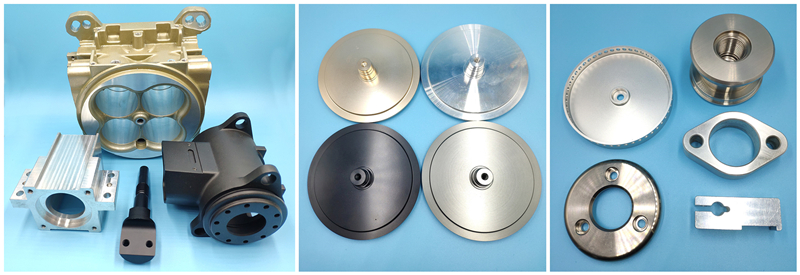

Product Detail:

Product name: CNC Milling Services Custom milling part

Material: aluminum, steel, brass ,plastic, carbon steel, nylon, PP

Dimensions: according to customer’s drawing

Surface treatment: Heat treatment, polishing, PVD/CVD coating, galvanized, electroplating, spraying, and painting.

Packing: PE bag, carton, wooden box

Very glad to know you are interested in our CNC machining service.

Delivery

Write your message here and send it to us