Precision Turning Components

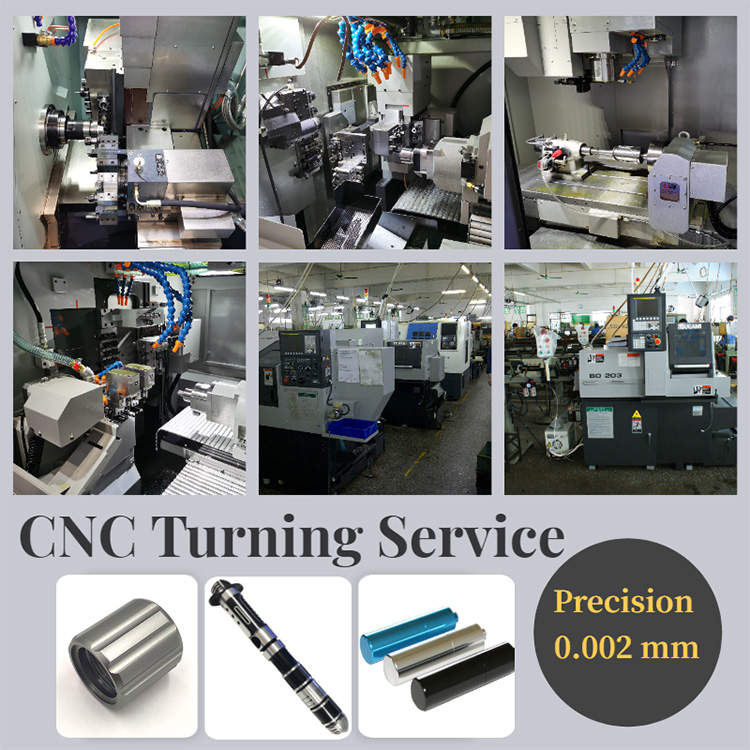

We have more than 30 precision machining equipments such as computer boring, CNC, milling machine, grinding machine, wire cutting, EDM machine, CNC, etc. It has strong comprehensive supporting ability and also we can provide mold design and manufacturing, injection molding, stamping workpiece or mechanical parts processing.

Applications: Cameras, communication chambers, consumer electronics,medical equipment accessories, mechanical equipment parts, automobiles, household appliances

Hot Tags: Turning part / Turning machining part / Turning milling part/Brass turning part / Brass gear part / Brass worm gear / Brass spur gear

Write your message here and send it to us